Modular 3D Printing for Research and Education

3D printing is an exciting technology that offers many advantages for education, both for pedagogical purposes and to fuel university research and development projects.

It can be utilized in universities, research laboratories, and fablabs in collaboration with academic authorities and companies.

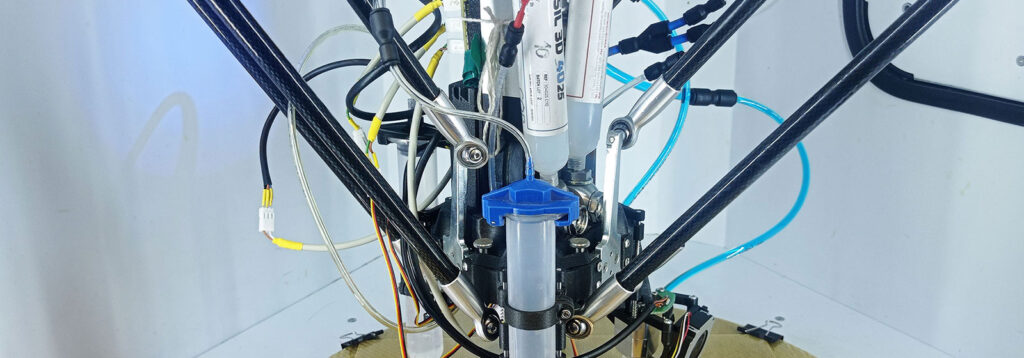

The S600D modular 3D printer in the research center of Sigma Clermont

WHY USE 3D PRINTING FOR EDUCATION?

The benefits of 3D printing for universities and research are numerous.

Today, 3D printing is used in universities for various applications and sectors such as engineering, art, research, and architecture. The modular nature of a 3D printer, like the S600D, which can print filaments, pastes, and liquids, provides a wider range of possibilities for both applications and printed materials. In particular, it can be used to fulfill different functions for a multitude of projects.

– Create prototypes and models : 3D printing is an excellent way to create physical models of complex shapes and designs. It allows researchers and engineers to quickly and easily create prototypes of new products or other parts, helping them better understand the performance of these new designs, identify potential defects or areas for improvement, and reduce development costs.

– Develop new materials : 3D printing enables the development of new materials for industry. Researchers and engineers explore and test new formulations or combinations of materials that can be used in 3D printing. The S600D makes it possible to print any material by combining “open source” bricks with an efficient industrial solution. This leads to the creation of new products and components with unique properties and capabilities, stimulating innovation in sectors such as aerospace, automotive, and healthcare.

– Customize: : 3D printing offers the possibility to create “highly” customized parts and components. This is relevant for the realization of single parts, such as for medical purpose with the making of prostheses and ortheses specific to a patient thanks to 3D silicone printing.

– Create tools : it is widely used to create specialized tools or molds for manufacturing processes. This reduces the cost and time required for tooling and makes manufacturing processes more efficient.

– Reverse engineering: : 3D printing is a perfect solution for reverse engineering existing products or parts. This is particularly useful in industries such as automotive or aerospace, where replacement parts may be lost, hard to find or simply no longer produced. It can also be used when existing parts need to be improved.

Thomas Batigne, Roland Lescure, Minister Delegate for Industry, and Karim Sinno during the French Industry Week.

In addition to these numerous applications, it has real individual benefits through its educational assets:

– Develop creativity and innovation : it encourages these values by allowing students and research labs to design and create their own objects, fostering an entrepreneurial and innovative spirit.

– Provide hands-on, agile learning : 3D printing gives students a practical learning experience that allows them to design, create, and test objects in real physical conditions. Modularity helps develop better agility skills and fosters their ability to design projects without limits, juggling from one technology to another.

– Develop problem-solving skills : additive manufacturing requires students to think critically and solve problems to create their products and have them be functional. It develops a logical mindset, where the student must experiment, question, evaluate, optimize, and iterate a product or object to serve a given problem or specification.

– Foster collaboration : 3D printing is a collaborative process that stimulates teamwork and communication skills. Students can work together to design and create objects, learning to share ideas, skills, and work together toward a common goal.

– Build your career : 3D printing is an increasingly important technology in many sectors, from industrial to medical. By acquiring additive manufacturing skills at school or university on an industrial machine like the S600D, students learn about additive manufacturing, modularity, and the use of an industrial machine. The young generation can then better prepare for the challenges of the future.

The drawbacks of 3D printing for universities.

Despite the numerous benefits to research and teaching, 3D printing also seems to have its limits…

3D printing can be seen as time-consuming : Some prints take several hours or even days to be complete, which can be frustrating for those who are accustomed to getting immediate results. However, it is important to note that production in general takes time, and compared to traditional manufacturing methods, 3D printing offers a much faster and cheaper solution.

Materials to print are limited : While the range of materials available for 3D printing is expanding, it remains limited compared to traditional manufacturing methods. This means that some designs cannot be produced, or require additional post-processing steps. However, the S600D is a revolutionary printer that can print filaments, pastes, and liquids, making it one of the few printers on the market today that can print all types of materials, from homemade to high-performance industrial off-the-shelf materials, regardless of brand and source.

3D printing is too complicated: : Some people find 3D printing to be a complex process that requires specialized software and business expertise, making it difficult to implement without the necessary skills or resources. However, Lynxter offers an additive manufacturing training program, an ergonomic software suite, and partners to develop business skills, making it easier for universities to adopt 3D printing technology.

3D printing uses plastic materials : 3D printing can generate a significant amount of waste, which can have negative environmental impacts. However, 3D printing is now one of the few economical manufacturing solutions for small and medium-sized series, which allows for greater control over the quantity to be produced. This means that it is possible to manufacture on demand and not in series, which significantly limits the generation of useless copies.

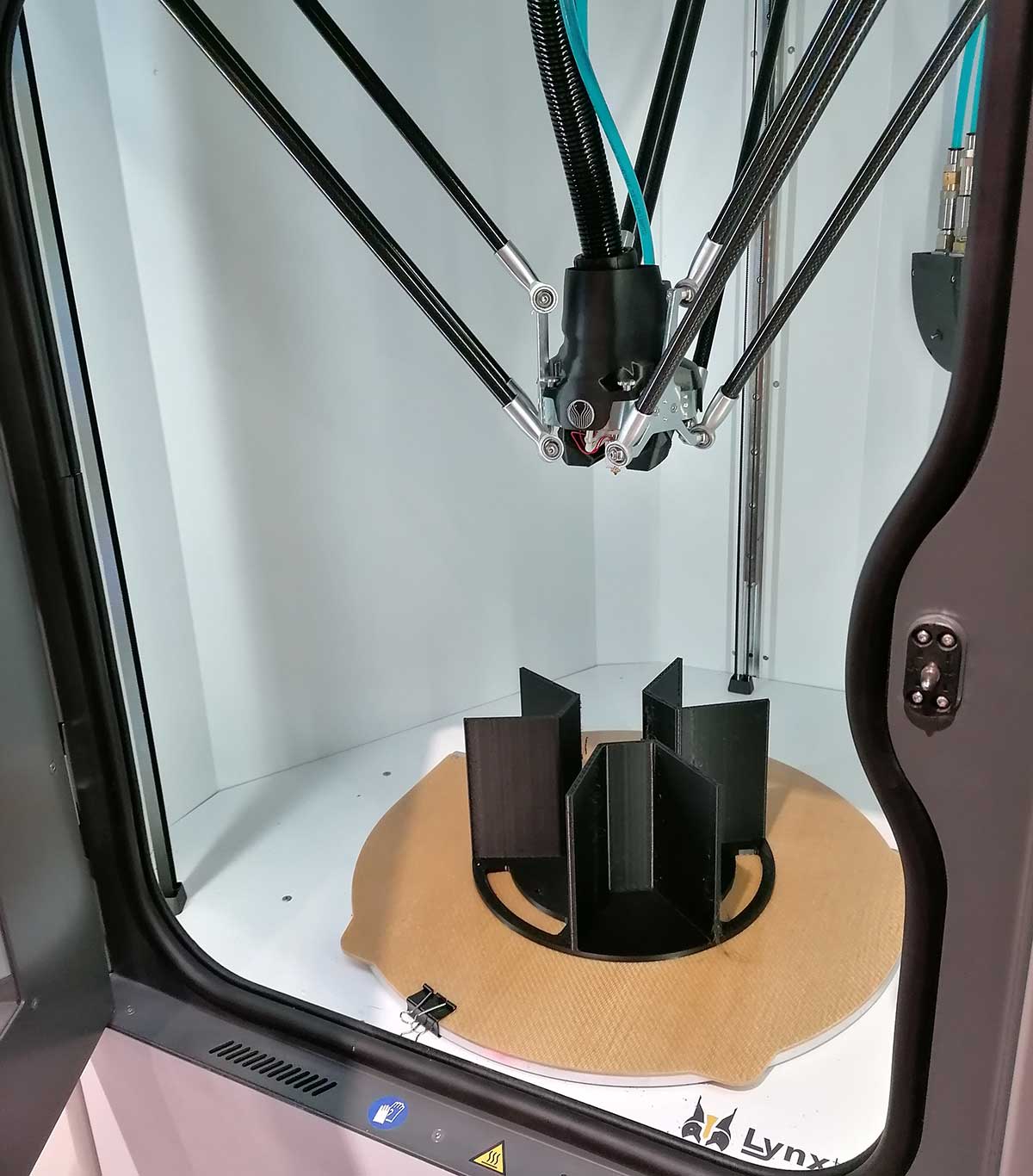

Project: Effect of wind on Gothic cathedrals by ENSAM – Model printed by the S600D – Source: ENSAM

Which universities in France are equipped with the S600D, a modular 3D printer by Lynxter?

Many universities in France are already using the S600D and its modularity for education and research and development (R&D) projects.

For example, as part of the PERSEUS project (Projet Étudiant de Recherche Spatiale Européen Universitaire et Scientifique), students from SIGMA Clermont were asked to work on a project related to launchers with the objective of projecting the students into a future of discoveries, science, and technology. They were required to create a rocket of about 2.5 m in length to test new technologies. As part of this project, the students used the S600D printer to make a large ejection chamber in PLA.

This project allowed the students to develop a collaboration with other schools, work as a team towards a common goal, and increase their skills in the field of launchers. They also had the opportunity to participate in the creation of a project step by step, from preparation to follow-up, progress, order, additive manufacturing, and finally, the launch of the rocket.

Ejection compartment made on the S600D – Source: Sigma Clermont

While we cannot disclose confidential projects and customers, many universities in France that are equipped with the professional 3D printer S600D are using the modularity of our solution to develop their research and teaching projects.

3D Printing for research and development :

– ADDIMADOUR works on various research and development projects on the theme of metal additive manufacturing. https://www.compositadour.com/

– Centrale Lyon uses the S600D to produce tools and prototypes for parts made of technical filaments (PA6-CF and PC) for aerodynamic and acoustic studies. https://www.ec-lyon.fr/

– COMPOSITIC BRETAGNE SUD tSUD works on material and process development projects in the field of polymers and composites. The S600D is also available to industrialists for research projects in the region. https://compositic.fr/

– CHU NÎMES works on the development of 3D printing of medicines. https://www.chu-nimes.fr/

– ENSAM / AEROPSACE VALLEY uses the S600D to print architectural models of different materials to measure the effects of wind on French historical heritage such as Notre-Dame de Paris. https://www.artsetmetiers.fr/fr

– ESILV aims to develop new intelligent materials integrating electronics at the heart of the material using the S600D. https://www.esilv.fr/

– ICMCB is developing research projects on the printing of metallic pastes with the S600D. https://www.icmcb-bordeaux.cnrs.fr/

– LMCPA CERAMATH UPHF éis studying the 3D printing of technical ceramic filaments in additive manufacturing using the S600D. https://www.uphf.fr/ceramaths

– POLYTECHNIQUE uses the S600D to manufacture functional prototypes as part of its support for entrepreneurial projects in the X-FAB Fablab. https://www.polytechnique.edu/

– SIGMA CLERMONT tworks on the development of new biosourced and/or biodegradable polymer materials for additive manufacturing (filaments and silicones). https://www.sigma-clermont.fr/fr

– Université Paris Diderot Diderot is printing various medical training materials (organs) on the S600D using several materials (thermoplastics, silicones, and hydrogels) https://u-paris.fr/

X-FAB, Industrial Prototyping and Development Centre of Polytechnique

3D printing for pedagogical teaching :

– CESI NANTERRE uses the S600D in filament configuration as part of the engineering curriculum to produce parts for student projects. https://paris.cesi.fr/

– ENSCM uses the S600D in paste configuration for student projects involving ceramic paste printing. https://www.enscm.fr/fr/

– ESTIA uses the S600D in filament configuration to teach the practice of additive manufacturing and the use of an innovative industrial tool as part of the engineering curriculum. https://www.estia.fr/

– UNIVERSITÉ PAUL SABATIER – INSTITUT CLEMENT ADER uses the S600D in filament configuration for student projects in the engineering curriculum. https://www.univ-tlse3.fr/

– LYCÉE GUSTAVE EIFFEL uses the S600D for student projects as part of the engineering curriculum – SSI industry / BTS. https://www.eiffel-bordeaux.org/

– INP TOULOUSE – ENSIACET uses the S600D in filament configuration as part of the engineering curriculum to produce parts for various student projects and to teach the practice of additive manufacturing. https://www.ensiacet.fr/fr/index.html

– PLASTINNOV LORRAINE works on application development projects for industrialists in the region and uses the S600D in a pedagogical framework for students who wish to discover liquid and paste additive manufacturing. https://plastinnov.univ-lorraine.fr/

*Non-exhaustive list

3D printing offers numerous benefits for research and development. The ability to create complex and customized prototypes, parts, and models rapidly and effortlessly has transformed the design and manufacturing process.

The S600D is an open and modular 3D printer that eliminates the limitations of other 3D printers, providing aspiring engineers and designers with a cost-effective and rapid means to test and refine their ideas with great flexibility. This fosters innovation and reduces the time required for product development cycles, enabling more efficient progress and greater success.