Using 3D printing for heritage preservation: the example of Notre-Dame de Paris

Scientific research is increasingly driven by environmental issues such as climate change, which are posing a growing threat to the preservation of emblematic buildings. This is notably the case for tall buildings such as the Notre-Dame de Paris cathedral. The preservation of architectural heritage is a major issue and links to our basic social and intellectual values.

Notre-Dame de Paris Cathedral in situ in the CRIACIV wind tunnel

This case study describes research carried out in the field of heritage preservation. This term describes activities that aim to identify, protect and highlight the most valued elements of the man-made environment such as buildings, monuments and sites created throughout the evolution of our land.

Several recent projects show the significant correlation between architectural and cultural heritage and climate change. Paolo Vannuci, Professor at the University of Versailles, is the man behind the Notre-Dame de Paris project. This experimental study, which has brought together an international and multidisciplinary team, focuses on the effects of wind pressure on the spire of the Notre-Dame de Paris cathedral and aims to provide a detailed assessment of the wind load that can be expected on different parts of the structure

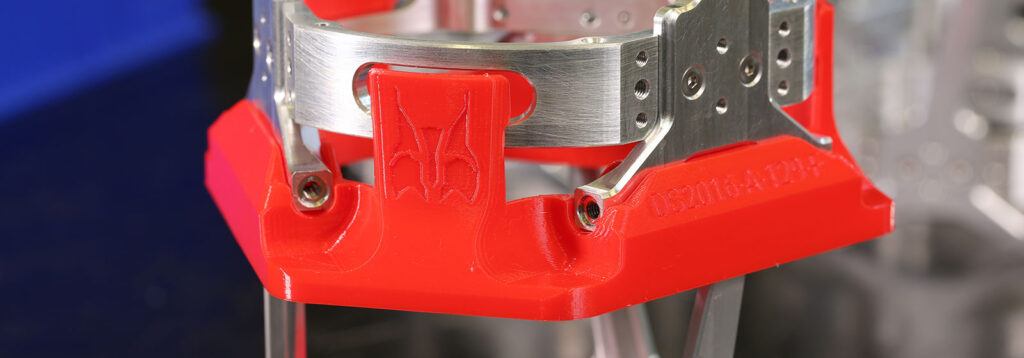

For the study, a model of the cathedral was 3D printed using the Lynxter S600D printer at the Arts & Métiers Institute of Technology (ENSAM).

3D printing is indeed an ideal tool for creating models for architectural projects.

The research process

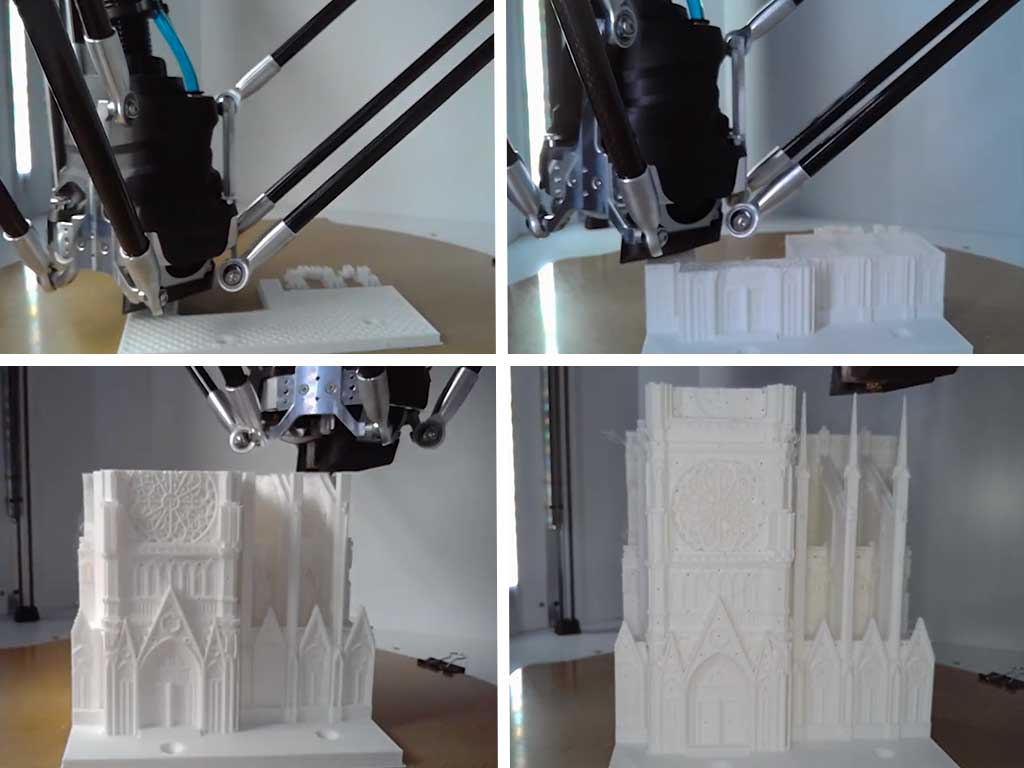

The experimental investigation is carried out in the wind tunnel of the CRIACIV (Inter-University Research Center on Building Aerodynamics and Wind Engineering) using a 3D printed model of the Notre-Dame de Paris cathedral, an emblematic structure of the Gothic period, by varying the intensity and the direction of the wind.

The idea is to recreate the cathedral and all the surrounding buildings within a radius of 200 meters at a scale of 1:200.

The building of the reduced scale replica had to meet various technical constraints.

One of the difficulties was to make a lifelike replica suitable for wind tunnel testing. For this testing, over one thousand pressure sensors are used, making it possible to obtain a map of the actions of the wind on the cathedral.

For this project, a partnership has been set up with the University of Versailles, the CRIACIV in Italy (with its internationally recognized expertise in wind tunnel testing) and the Institute of technology Arts & Métiers Bordeaux-Talence campus (l’ENSAM) where the 3D model was designed and printed.

The Bordeaux-Talence campus has been working on polymer and composite 3D printing for several years. Among its machines, the ENSAM uses a Lynxter S600D with a FIL11 toolhead. Versatile, open and with a large build volume, the Lynxter 3D printer is the ideal solution for the campus’ innovative and dynamic research projects.

Why 3D printing is useful for building architectural models

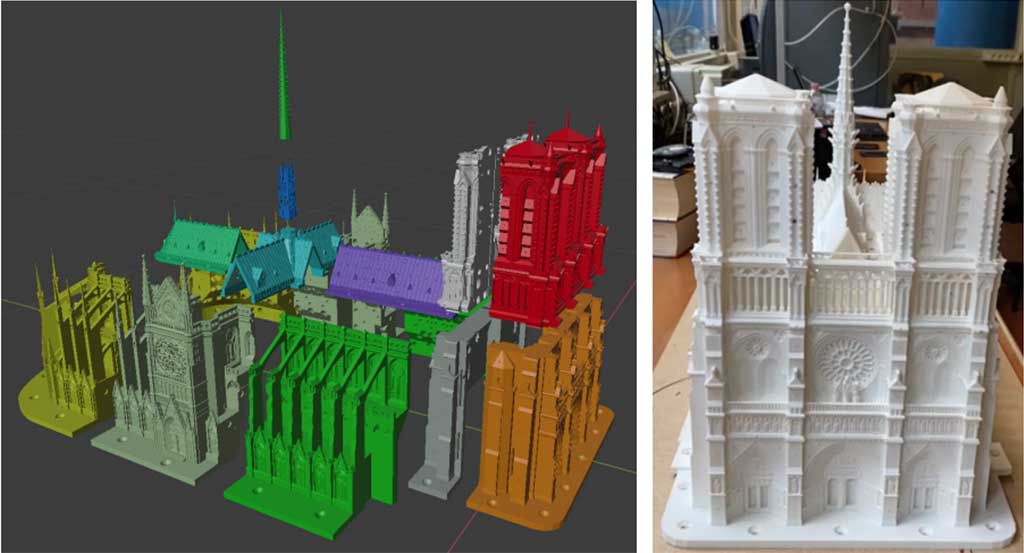

The complexity of a building and the influence of its environment mean that an experimental approach is required. The 1/200th scale model of the Notre-Dame de Paris cathedral was created in two phases:

– Design of a 3D model of the cathedral, suitable for the tests.

– 3D printing and assembly of the model.

On the left, the 15 digital parts, on the right, the printed and assembled model

3D printing proves to be the only real option given the complexity of the model, due not only to the cathedral’s geometry but also to its integration into the whole 3D model and the holes required to hold the pressure sensors.

A significant advantage of 3D printing is its ability to scale models. Possibilities are endless! In this specific case, the thirteen parts were printed and then assembled with magnets to make the final part.

Another big advantage of 3D printing is the ability to produce objects that are not only complex in shape but that can also be made of different materials.

3D printing also provides better control over the end product and makes modifications simple to do.

Due to the dimensions and geometric complexity of the cathedral model, material extrusion technology (MEX or FFF or FDM) was chosen. For some parts, notably the spire, which required spatial resolution, the SLA (Stereolitography) 3D printing technology was used.

Notre-Dame de Paris 3D Printing with the Lynxter S600D

The S600D 3D printer, at the heart of the project

The replica model of the cathedral was entirely 3D printed.

The 3D printing technology used was filament-based. Given the size of the model, Enrique Panettieri, professor-researcher at ENSAM and in charge of the project, chose to use the Lynxter S600D. With its large build volume, excellent print quality and high level of autonomy, the S600D was the obvious choice for printing the replica model of the Notre-Dame-de-Paris cathedral.

“The S600D offers excellent printing performance and a large build plate”, E. Panettieri

Moreover, the printer settings are very precise and easy to adjust, making it simple to use.

E.Panettieri, professor- researcher at ENSAM

It took about 2 weeks to make the thirteen parts of the cathedral model which were then assembled together. The model was sent to CRIACIV where it was set up on a rotating table. The wind tunnel testing was carried out at the end of 2021 using different configurations in order to vary the intensity and the direction of the wind. So far, the first results are very promising and will be the subject of a forthcoming scientific publication.

Future experiments

The next step of the project will be to use this data to investigate structural design and validation methods. What’s more, these same models could be used to more accurately assess the actions of the wind on the spire for improved structural validation.

3D printing is an innovative method used in multiple high-tech disciplines. Its customization capabilities make it widely used in Research & Development. 3D printing could also be used in other sectors to strengthen research and build knowledge in specific fields.

References

P. Vannucci – Experimental study of the wind pressure field on the Notre Dame Cathedral in Paris, May 27, 2022 (arXiv:2205.13391).

CRIACIV – RAIUno Channel – Unomattina Estate in the CRIACIV Wind tunnel.

You should read

ADVANTAGES OF 3D PRINTED SILICONE FOR SOFT ROBOTICS

SILICONE 3D PRINTING: HOW AND WHY PRINT SILICONE?

HOW TO REDUCE THE WEIGHT OF METAL PARTS BY 70% WITH 3D PRINTING