Open 3D Printing: The Smart Choice for R&D

The S600D 3D printer offers the flexibility, durability, and scalability of an open system while providing the ergonomics, efficiency, and power of an industrial-grade solution. This openness sets it apart from its peers, particularly in its ability to add third-party equipment, print new materials, and interface with other software.

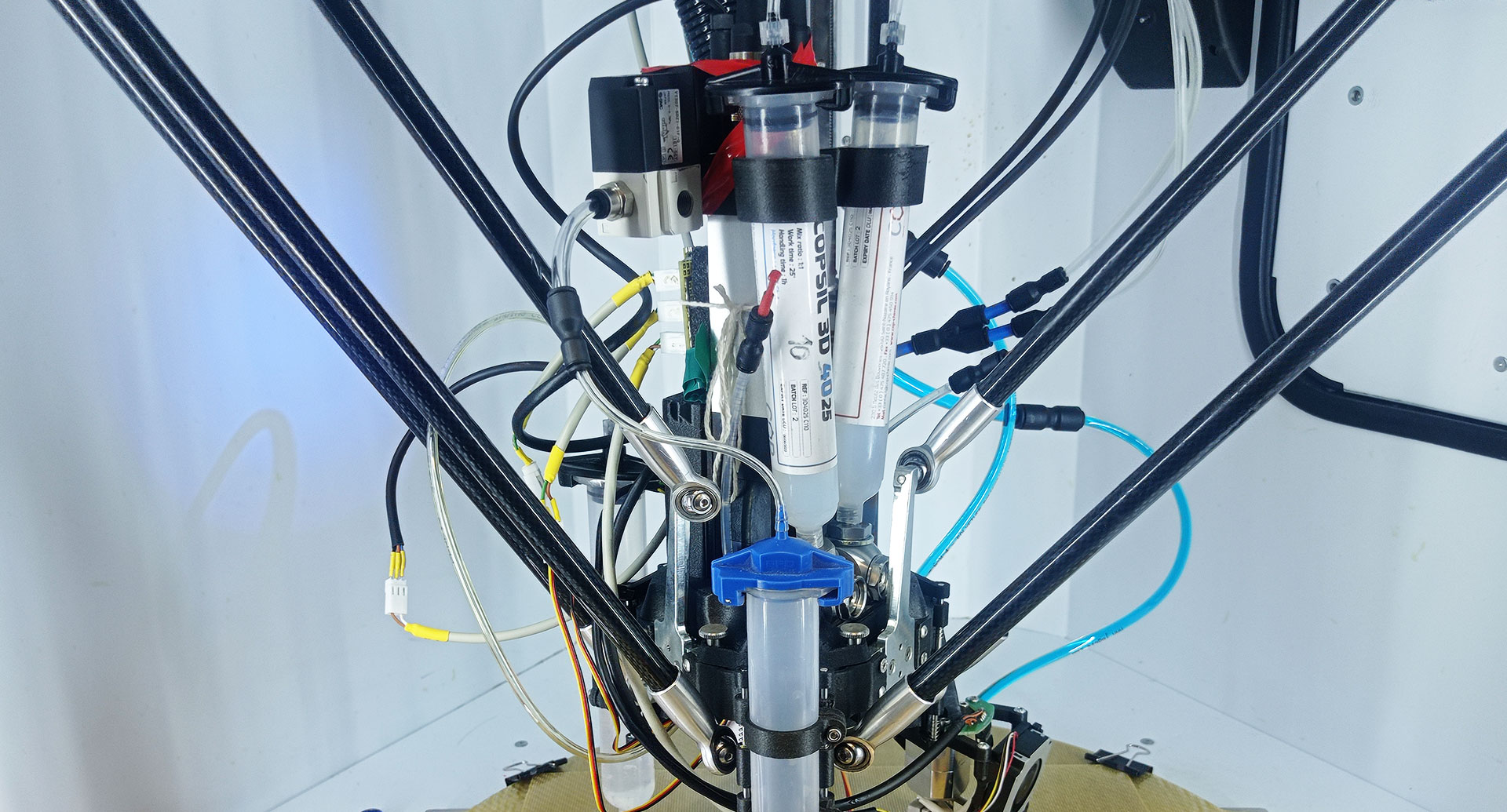

Custom tool head developed for research

WHAT IS “OPEN” TECHNOLOGY?

Today, there are several forms of openness, including free vs. proprietary, open vs. closed, and different “licenses” or degrees of accessibility regarding source code, program functioning, or distribution. Open technologies are in direct contrast to the closed technologies typically found in proprietary services or machines that evolve only at the whim of the company that develops them.

Some of the main types of open elements are:

Open-Source Software: it is software whose source code is publicly available and which can be used, modified, and distributed by anyone under a license that allows such actions (e.g., Linux, Apache, MySQL). The license is essential in defining the possible scope of action of the public on the software.

Open Data : it is data that is free for all to access, use, and distribute. Open data is often used for research, innovation, and the development of new products and services.

Open Hardware : it is hardware whose design is publicly available and can be modified, distributed, and built by anyone (e.g., Arduino, Raspberry Pi).

Open Standards : These standards are openly available and can be used by anyone to develop interoperable systems and technologies. Open standards are essential to ensure compatibility between different technologies and avoid vendor lock-in.

Open APIs :These APIs (application programming interfaces) are publicly available without limits and in a comprehensive way (coverage of software functions in APIs).

Open technologies have many advantages. They often have a much longer lifespan than closed technologies, are more flexible, and offer the possibility to be customized and integrated with other technologies to meet specific needs and requirements. Most importantly, they often lead to more innovation, as they allow more people to experiment, create, exploit, and evolve these technologies.

3D printer S600D from Synthene for PU printing research.Sources : Synthene – Cedric Meschke

The S600D 3D printer incorporates some of the main principles of openness, combining the freedom of some open standards with the reliability of an industrial design. At Lynxter, we want our users to be able to modify the machine according to their needs and thus make our products evolve with usage.*

– The machine software is based on an open REST API.

– The Duet electronic boards that make up the machine are open source.

– Some of the machine’s programs and macros can be freely modified by users: new functions or third-party software can be added to the system.

– The choice of slicer is free, open-source solutions exist and allow the development of one’s parameters for any type of material.

– There is no “proprietary” packaging for materials (e.g., material cassette with identification chip). There is no “material” closure; all possible materials can be printed, regardless of the brand and regardless of its formulation, making it perfectly suited to the search for composite materials.

– Although the design of the machine is not open to free reproduction, the printer offers open hardware:

The machine’s connectivity is accessible and documented, so equipment can be added that opens, for example, new extrusion modes to print new materials or new material combinations.

Adding new accessories is easy. For example, new cooling equipment, UV exposure equipment, or an additional movement axis such as the rotation of the tool head can be integrated.

THE S600D, A PRINTER OPEN TO ALL TOOLS

Brice Parilusyan, a PhD student at the Devinci Innovation Center, is currently preparing a thesis in Soft Robotics. He was able to test the capabilities of the S600D in integrating external technology.

During his research, Brice became interested in multi-process printing, which consists of using several printing processes on the same part: he needed both MEX (FFF-FDM Fused Deposition Modeling) and DIW (Direct Ink Writing). He modified an existing Lynxter printhead to use both processes simultaneously and print 4 materials with different properties in the same part.

A customized four-extrusion toolhead was developed as part of the research.

It took Brice 6 weeks to get a fully functional system:

The first step was the design and modification of the physical extensions.

The second step was to control these extensions without risking damage to the machine and hardware.

The last step was the integration of the tool into the machine’s software.

Brice encountered two obstacles during this work:

As a precursor to this work, he did not have the necessary documentation on tool creation and integration. “I had to proceed step by step with a lot of caution in order to avoid making too much damage and to understand what I was doing.”

This feedback led the Lynxter team to offer special support and work on building the documentation necessary for this type of development.

“I reached the limits of the electronic boards and had to make additional electronic extensions to control the print head.”

Although the existing electronic boards themselves had their limits, the machine again made it possible to overcome this barrier by integrating extensions. So Brice pushed the machine to its limits and managed to get the system to work the way he wanted.

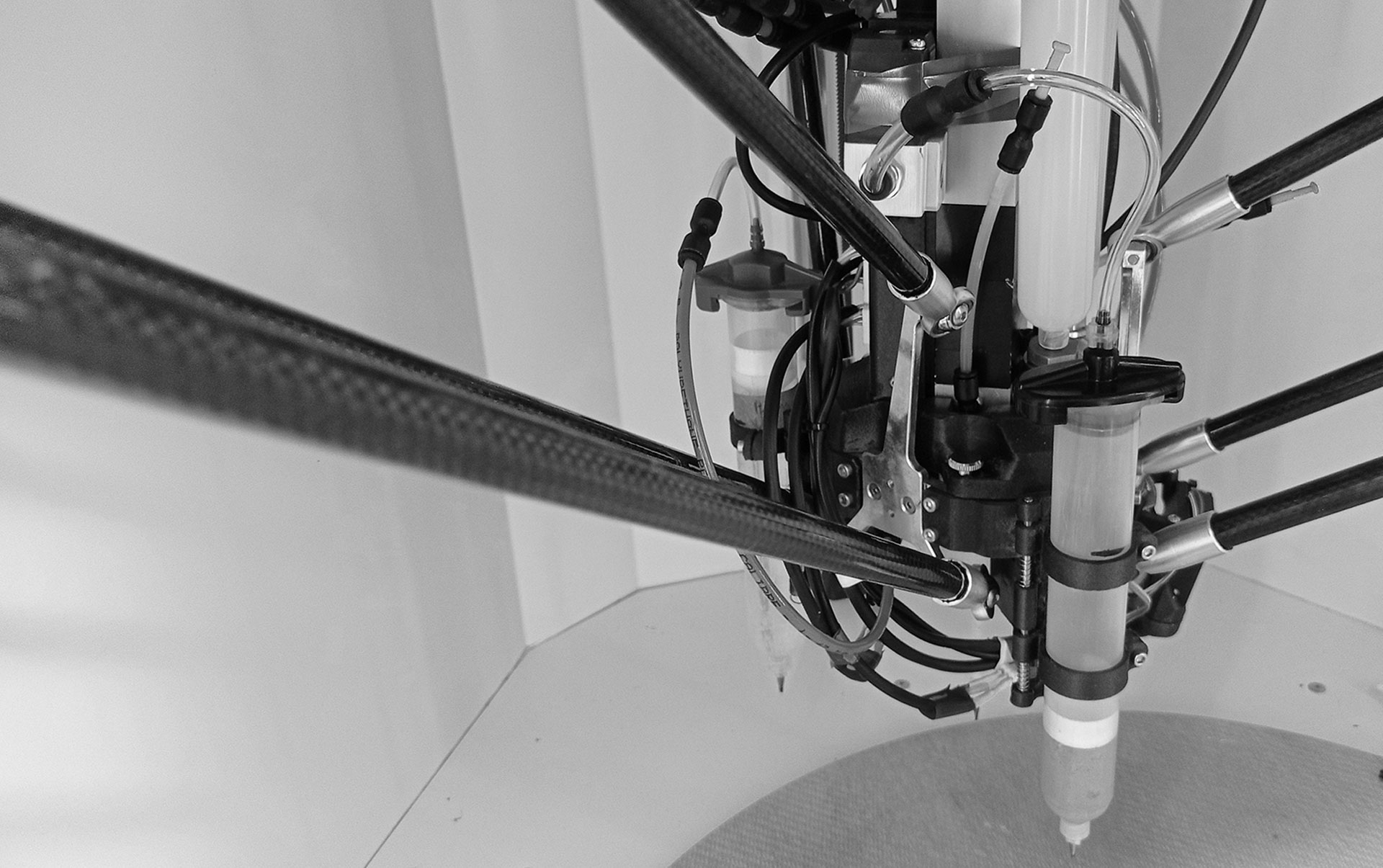

An example of an interchangeable tool head on the S600D.

THE S600D: A PRINTER OPEN TO ALL MATERIALS.

Many 3D printers on the market print a wide range of materials. However, only Lynxter’s S600D industrial 3D printer offers the possibility to print filaments, pastes (porcelain, ceramic), and liquids (silicone, PU) on the same machine, thanks to its interchangeable print heads.

In “mono-material” filament configuration, the S600D industrial 3D printer has a thermo-regulated chamber that ensures the printing of a very wide variety of thermoplastics, including the most common ones such as ABS, PLA, Nylon, or PETG, flexible ones such as TPU, TPE, or techniques such as PEKK-A, PC, and The PA6-CF.

The S600D is still one of the most flexible printers for the integration of new materials, regardless of brand, origin, or formulation.

To sum up:

HARDWARE

| S600D open industrial 3D printer | Industrial closed 3D printers | |

| Add or modify a printing tool | Yes on request | No |

| Add or modify an option (heating, etc,) | Available on LIQ PAS toolheads | No |

| Add or modify accessories (camera …) | USB-A connector | N/A |

| Add or modify a supply rack | Accompaniment on request | No |

| Electronic card | Duet 3D (free and secure) | Closed – proprietary |

| Buses compatibles | In FIL: liquid cooling receptacle, M6 short and long (Type E3D V6 or VOLCANO) In LIQ and PAS: Luer lock, static mix adapter |

N/A |

| Compatible materials | Unlimted – open to all materials (filament, liquid, paste) | Limited to those produced by the company |

SOFTWARE

| S600D open industrial 3D printer | Industrials closed 3D printers | |

| Machine server operating systems | Linux, based on free Ubuntu software | Proprietary system or non-free Windows |

| Compatibility of the machine control software | All media compatible (Windows, Linux, Mac Os – Desktop, tablet, Smartphone) | Windows and PC |

| Programming of specific functions | Yes via gcode macros | Generally not (check with company) |

| Connectivity with third party software (API) | Yes, simple REST API for V1 of Lynxter software, complete for V2. Most widely used inter-software communication protocol (open data) |

Often paid for – Protocol not widely used as SDK. Connectivity difficult. |

| Compatible slicers | Open to all – Lynxter offers profiles on simplify 3D | Closed – specific to the company’s ecosystem |

| Machine calibration | Customisable calibration | One calibration mode available |

| Security | Full user access configuration on V2 software | Pre-defined and restricted access and administration |

DATA

| S600D open industrial 3D printer | Industrials closed 3D printers | |

| Data history | Available on V2 | Available |

| Data Sharing | Complete via REST API | Restricted |

| Print profiles | Accessible and editable | closed – not editable |

| Process and documentation | Fully configurable on V2 – documentation : pdf – paper- video | Documentation : pdf – paper |

At Lynxter, the openness of our technologies governs the way we work and develop. It is through collaboration, agility, and customization that we aim to deliver better 3D printing solutions for industry, healthcare, and research.

Want to lean more about this matter? Contact our team.

*As we cannot control the modifications made by our customers, any modification that has not been expressly approved by the manufacturer or registrant of the S600D (Lynxter) may void any warranty.