Fablab and 3D printing : Myriam Delprat, Fabmanager

Today, many places offer the possibility to train and produce your own parts in 3D printing. This is for example the main objective of a fablab.

A fablab (Fabrication Laboratory) provides a platform of manufacturing machines to innovators, entrepreneurs and individuals to create prototypes, test designs and manufacture products. 3D printing is a big part of this. Myriam Delprat of the Saint-Céré fablab explains why owning an industrial 3D printer opens the fablab to industrial players.

Myriam Delprat, Fabmanager at Quart Lieu Cauvaldor

Who are you?

Myriam Delprat, I am Fabmanager at Quart Lieu Cauvaldor, the Fablab of Saint-Céré, in Occitanie.

I trained as a mechanical engineer at the Arts et Métiers ParisTech school. I mainly worked as a CAD/CAM engineer in the food and aeronautics industry for 13 years on the machining part, and more particularly on the tool path for numerical control machines.

The confinement of the COVID 19 caused a great upheaval in the sector, my work was directly affected, and the department closed. After working on an innovative personal project, but too ambitious and too risky in this post-crisis period, I had the opportunity to join the fablab of Saint-Céré as a Fabmanager, a great project that allows me to help the public to use manufacturing machines.

My role is to manage and promote the activities and services of the fablab to all the actors of the region, from individuals to multinationals.

When I arrived, I didn’t know about additive manufacturing. I trained with my collaborator Guillaume, and Fabien Plassard, R&D engineer at THIOT Ingénierie, on small machines and then on larger ones such as the Lynxter S600D industrial printer.

What is a fablab?

A fablab is a place of sharing based on collaborative work. The fablab of Saint-Céré provides a set of professional machines for all audiences: individuals, associations, professionals, self-entrepreneurs, micro-businesses, schools, or high schools.

Supported by a local authority, this allows the fablab to offer low prices for use with a permanent supervision by two animators (Guillaume and myself).

The fablab does not subcontract, it is there to accompany, to facilitate the handling of the machines by the beginners or by the professionals already trained. The objective is for the public to come and appropriate the machines like the S600D.

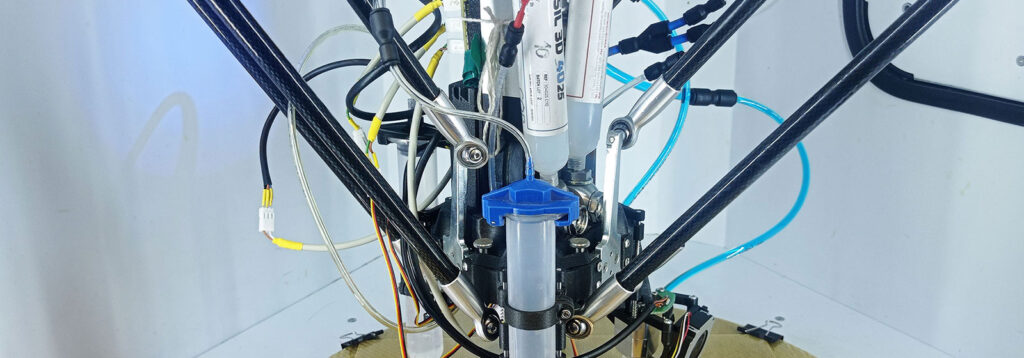

Today, the Saint-Céré fablab has three 3D printers with three different processes, including the S600D in MEX Delta printing, a 3D scanner, a digital embroidery machine, and a laser cutter.

The fablab of Saint-Céré welcomes everyone

What is the interest for a fablab to integrate an industrial 3D printer like the S600D?

The use of 3D printing is still unclear for some industrialists and private individuals. The proximity and practice of the technology allow them to lift this veil and to consider a new production behavior.

Integrating an industrial 3D printer allows a fablab to open to new industrial projects, and conversely, it allows regional manufacturers to test, train, and develop their skills and projects in 3D printing.

Industrial 3D printers can use a wider range of materials, including high-performance polymers, which allows for more durable prints for companies. The Saint-Céré fablab is located in a basin of industrial companies with players such as THIOT Ingénierie, Andros, Five, Add up, some of which are already members and have already produced parts within the Quart Lieu.

We mainly print large-volume parts and prototypes in ABS filaments for companies with the S600D. Equipped with FIL11, FIL21 and FIL33 tool heads, and two other 3D printers, the fablab can print a wide variety of materials from TPU to PA6-CF.

3D printing made by the Fablab “Le Quart-Lieu” on the S600D

What applications do you make in the fablab?

For a private individual.

For example, a person came to us to reproduce a 50-year-old piano tuner. We scanned the damaged part, and then reprinted it. We have also printed old car door handles that are no longer produced today.

For a company.

We collaborated with the company Fives who designs and manufactures machines. They had to produce a machined part, a 15 cm diameter tooling containing different holes, for one of its customers. This part had to be reproduced very quickly for tests. Fives could not find anyone who could remanufacture the part, so they called the Saint-Céré fablab to print it in 3D.

Printed in less than a day, the part was produced in ABS and PC. Fives’ customer was very skeptical about the use of 3D printing. The result… this part saved him more than 3 months of production.

Myriam Delprat and Fabien Plassard (THIOT Ingénierie) trained the Andros company to use the S600D

What is missing in 3D printing today?

It is not easy for individuals and companies to project themselves in “3D”. There is still too much vagueness about 3D printing and its function. The younger generation is not trained yet on additive manufacturing. Sometimes teachers get investments to acquire machines, but few students can use the printers once purchased. “They are not allowed to touch them”. Only the teacher has access.

We are trying to introduce everyone to additive manufacturing. We have already received middle and high schools for which we propose animations of laser cutting and 3D printing. They discover the different printing methods and take part in fun games to learn to distinguish printed and assembled objects, for example.

It is important to develop strong networks between users to grow and share. The fabLab Quart lieu is part of the RedLab network which gathers all the fablabs in Occitania. This favors the exchange of our projects and our experiences. Thanks to this, we are in permanent evolution on our services and our know-how.

Initiation of children and teenagers to 3D printing at the fablab of Saint-Céré

An industrial 3D printer can be a valuable investment for a fablab, enabling it to produce high-quality, complex parts and prototypes and improve its ability to innovate, design and manufacture products. However, it’s critical to assess the specific needs of your fablab and determine if an industrial 3D printer is the best option.

Want to lean more about this matter? Contact our team.