Which industries use silicone 3D printing for maintenance?

“Silicone additive manufacturing transforms maintenance: faster, more economical, more sustainable.” –

Antonin Petit-Brisson, Sales Engineer at Lynxter

A concrete solution to industrial maintenance challenges

In the field of industrial maintenance, production shutdowns caused by the failure of a silicone or polyurethane part are not uncommon: silent blocks, seals, stops, dampers, etc. These components, while essential to the proper functioning of machines, are often difficult to replace once worn or damaged. Manufacturers then face several well-known obstacles:

• Suppliers no longer offering the required reference

• Minimum order quantities far exceeding actual needs

• Prohibitive unit costs for small series

• And above all, supply lead times incompatible with the urgency of getting back into operation

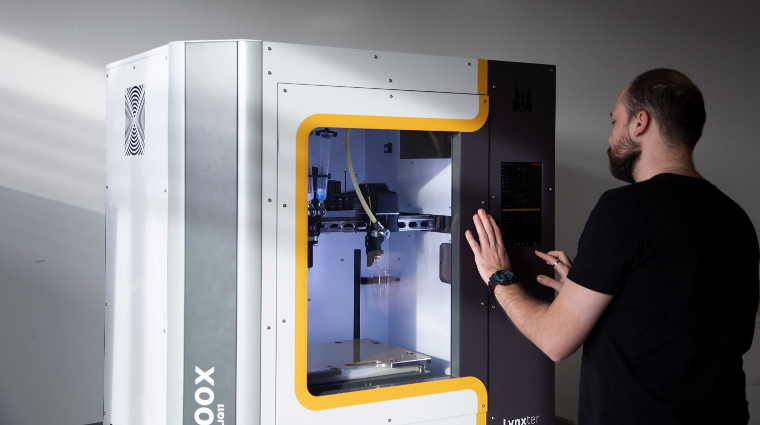

The S300X – LIQ21 | LIQ11, prints silicone for industry

It is precisely in this critical context that elastomer 3D printing proves to be a breakthrough solution. Thanks to advances in technology, particularly in direct printing of complex materials like silicone, it is now possible to produce parts with mechanical performance equivalent to the original, without tooling or molds, and in record time.

Our technology enables:

• On-demand manufacturing of functional parts

• A drastic reduction in response times

• Better cost and stock management

• Increased autonomy for maintenance teams

“Our clients, even without technical expertise, can produce functional parts in just a few hours.” – Antonin Petit-Brisson

By bringing production closer to maintenance workshops, silicone 3D printing helps strengthen industrial resilience.

Which industries use silicone 3D printing for maintenance?

In sectors like rail, automotive, manufacturing, defense, and surface coating, silicone additive manufacturing stands out as a fast, economical, and custom solution. Let’s explore a few examples of how silicone and PU 3D printing can be applied:

APS Coating Solutions

This company, specialized in dry coating applications, uses silicone additive manufacturing for its masking solutions and maintenance challenges.

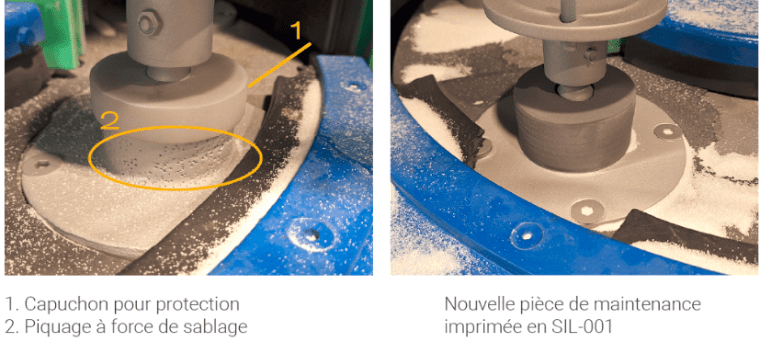

Case #1: Replace and improve a sandblaster cap with 3D printing

On a high-productivity industrial sandblaster (carousel with 8 satellites, multi-nozzle corundum projection), parts under the satellites are constantly exposed to abrasion. The original cap, inefficient and expensive (≈€100), must be frequently replaced, causing production stoppages.

Thanks to 3D printing, a new part was designed:

• More resistant to wear

• Optimized for better coverage

• Cheaper to produce

• Easily printed in-house

Industrial benefit: this solution not only reproduces the part but improves it, extending equipment life while reducing maintenance costs.

Silicone-printed protection cap

Case #2: Protect cooling nozzles exposed to thermal spray

During plasma spray processes, “vortex” cooling nozzles can be exposed to direct heat flows or material rebound, causing:

• Blockages due to coating buildup

• Premature wear

• Costly failures

To protect them, APS Coating Solutions designed a custom-fit 3D-printed silicone sock for each nozzle geometry.

Advantages of the 3D-printed solution:

• Heat resistance up to 250°C

• Custom design with precise fit

• Fast and on-demand production

• Cost reduction, even for small batches

“Thanks to silicone 3D printing, we can design custom, durable, and economical protections, deliverable within hours.”

Antonin Petit-Brisson, Sales Engineer at Lynxter – APS Coating Solutions

3D-printed silicone protective sock

SNCF

Case #3: Using silicone 3D printing to replace a critical sealing gasket

Faced with a stock shortage of sealing bellows—flexible components essential to the railway braking system—SNCF opted for an innovative silicone 3D printing solution.

Thanks to 3D printing, the company was able to:

• Reproduce the part on-demand with a custom fit

• Ensure functionality equivalent to the original

• Significantly reduce replacement lead times and costs

Rail maintenance and 3D printing: this case shows how flexible and technical parts can be reproduced locally without relying on suppliers or suffering critical delays.

3D-printed silicone bellows for SNCF and clamping jaws for Saprena

SAPRENA

Case #4: Designing 3D-printed clamping jaws to adapt the production line

Faced with the introduction of new detergent caps on a packaging line, Saprena had to quickly modify its clamping jaws—specific tooling parts used to hold products during processing.

Using the S300X SIL21 | SIL11, the company was able to:

• Internally print its own clamping jaws

• Quickly adapt its tooling

• Maintain production without interruption

Soft tooling 3D printing: an ideal solution for temporary adaptations or format changes without stopping the line or outsourcing costs.

A turnkey solution for manufacturers

Lynxter, a global reference in silicone 3D printing, does more than just sell printers. The company offers complete support, from design to production:

• Technical diagnostics to target use cases

• CAD / slicer / machine training

• 3D modeling support via measurement or 3D scan

• Material advice and print strategy guidance

“Our goal is not to reproduce identically but to optimize and even improve the function of the part.” – Antonin Petit-Brisson

Lynxter’s range of industrial 3D printers

Conclusion: A future-ready technology available today

In summary, silicone 3D printing is emerging as an agile and efficient response to the challenges of industrial maintenance. It enables the local, on-demand production of custom technical parts while reducing lead times and costs. A pioneer in this field, Lynxter supports manufacturers in making their maintenance more responsive, autonomous, and sustainable through mastered technology and recognized expertise.

INDUSTRIAL SEALING WITH SILICONE AND PU 3D PRINTING

Download our e-book

Discover in just a few pages the possibilities offered by silicone and polyurethane 3D printing for industrial sealing applications, such as making gaskets, bellows, and much more.