Defense Enhancement: The Benefits of Modular AM in Expedient Repair

This article explores the advantages of modular 3D printing in the defense sector, with a focus on customization, complex geometries for stealth, and reduced reliance on external suppliers. It shows how the technology optimizes operational effectiveness through rapid prototyping and lightweight design. With highlights from the AM Village event, you will see how Lynxter showcased the capabilities of modular 3D printing in military applications.

Modular 3D printing can offer several benefits

In the defense sector, the adoption of modular 3D printing holds significant potential for numerous benefits:

Answer to specific mission objectives and needs : Defense requirements often vary based on mission objectives and individual soldier needs. With modular 3D printing, it becomes easier to customize and personalize equipment and gear. Soldiers can have access to tailored solutions that fit their specific requirements, resulting in enhanced comfort, performance, and safety. Modular 3D printing can facilitate the production of complex geometries and surface textures that aid in stealth and camouflage. Defense entities can create intricate patterns or structures on equipment and vehicles, enhancing their ability to blend into different environments or avoid detection by radar or other sensors.

Example of how 3D printing benefits Defense at the AM village event

Minimize downtime and accelerate repair : The defense sector heavily relies on complex and often lengthy supply chains for critical components. By incorporating modular 3D printing, defense organizations can enhance their agility and independence in producing specific parts and accelerate both Expedient repair (ER) and Battle Damage Repair (BDR).

Deployed military units often face challenges when it comes to repairing or replacing damaged equipment or components on the field. Expedient Repair (ER) refers to a temporary or makeshift repair method until more permanent repairs can be conducted. ER needs to be quick and effective. In ER scenarios, where time is critical, 3D printing allows for the rapid production of replacement parts and brings flexibility that allows the production of tailored components that match the exact specifications required for ER (material, exterior condition, shape, support assimilation).

This resilience is particularly valuable in situations where the supply chain may be disrupted, such as during conflicts or in remote locations. Battle Damage Repair (BDR) refers to the process of repairing and restoring damaged military equipment or vehicles that have been affected by combat or other hostile actions. It is crucial to quickly restore the functionality of the equipment and operational readiness with reliable parts. With modular 3D printing capabilities, soldiers can produce replacement parts or repair tools on-site. This enables quicker turnaround times, ensures operational capability, and minimizes downtime.

Overcoming obsolescence challenges: : 3D printing plays a crucial role in overcoming challenges posed by outdated or obsolete components. It enables the reproduction of discontinued or hard-to-find parts, offering a solution for defense organizations to effectively address these issues and extend the lifespan of aging military equipment. Through the process of reverse engineering, exact replicas of damaged parts that are no longer in production can be created. Moreover, this approach facilitates the development of upgraded versions of these components, significantly enhancing the performance and functionality of the equipment.

Daily debrief from the AM event with Lynxter

Optimize operational effectiveness : 3D printing enables the quick and cost-effective production of prototypes. Defense organizations can use 3D printing to create and test various design iterations of equipment and materials, systems, and components. This allows for faster development cycles and reduces the time it takes to bring new technologies to the field. Defense organizations can optimize designs for lightweight structures without compromising strength or functionality: it improves mobility, fuel efficiency, and overall operational effectiveness.

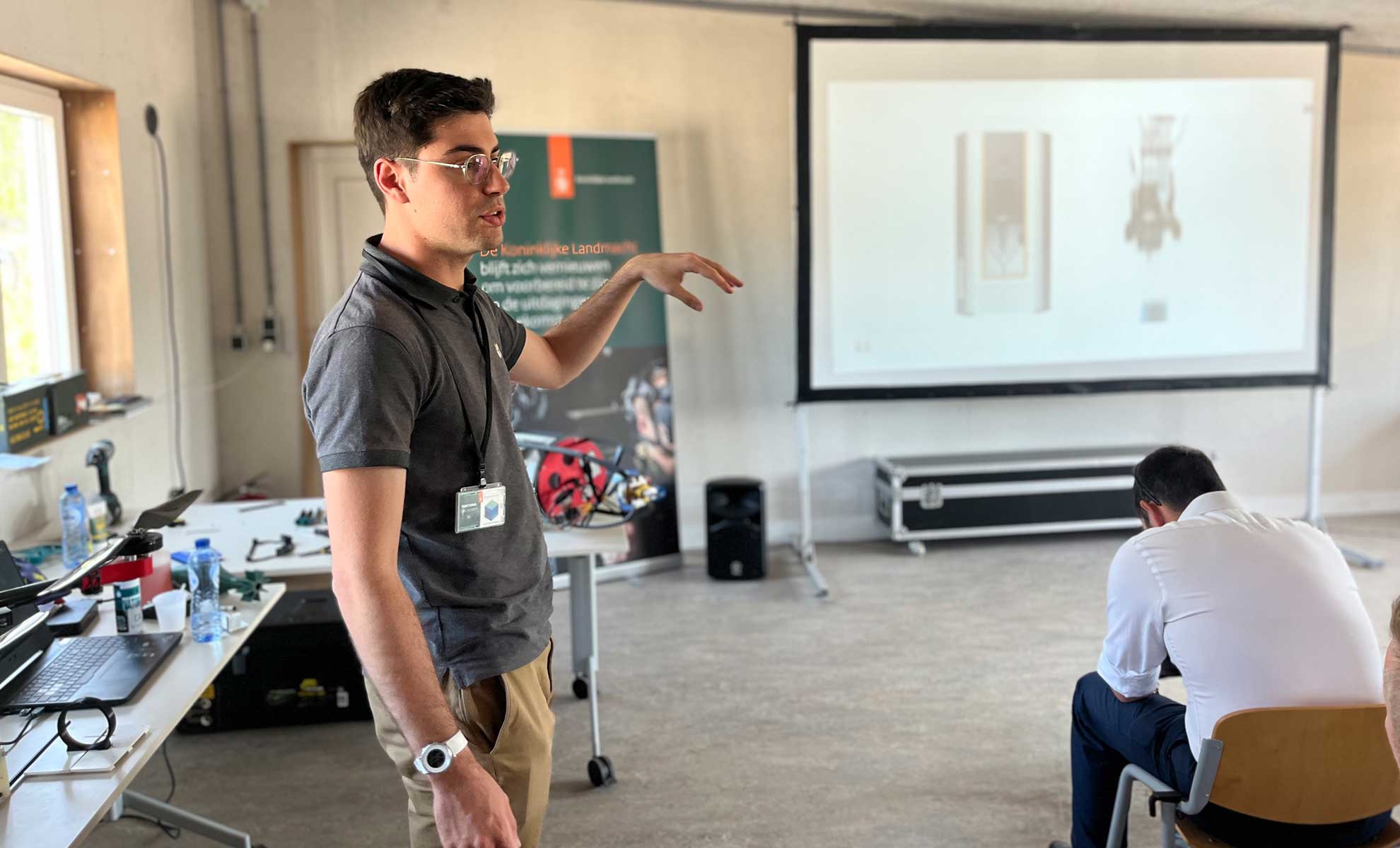

Thomas Batigne presenting Lynxter 3D printing solutions at the AM village event

AM Village

The European Defense Agency (EDA) is organizing “AM Village 2023”, the first European military Additive Manufacturing (AM) capability development workshop bringing together industrial AM capabilities and military AM experts. The event took place from 12-16 June 2023 in Ede, The Netherlands, at the Koninklijke Ladmacht’s Fieldlab Smartbase. The Multinational Logistics Coordination Center (MLCC) is supporting the event in cooperation with the Dutch armed forces.

Karim Sinno from Lynxter and Antony Martin, Additive Manufacturing expert from the DGA at AM Village 2023

The AM Village 2023 aims to define military use cases – focusing on deployed military missions – and to identify appropriate AM technologies which can provide logistic advantages to deployed armed forces. The event was composed of industry demonstrations and academic workshops, aimed at fostering cooperation amongst various stakeholders working towards interoperability for AM applications for military purposes. Lynxter was among the 250 participants.

The Multinational Logistics Coordination Centre (MLCC) is an organization that facilitates multinational coordination and cooperation in logistics within the defense sector. It played an important part in the AM village event: it connected participating nations, organizations and 3D printer manufacturer to work together so they could contribute to the overall effectiveness of multinational defense operations and humanitarian missions

5 days of concrete application workshop

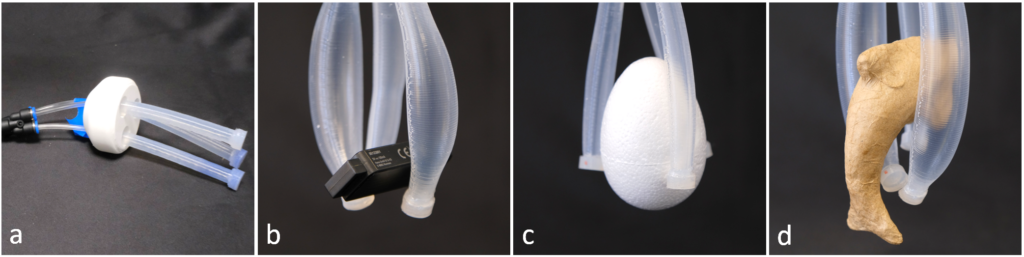

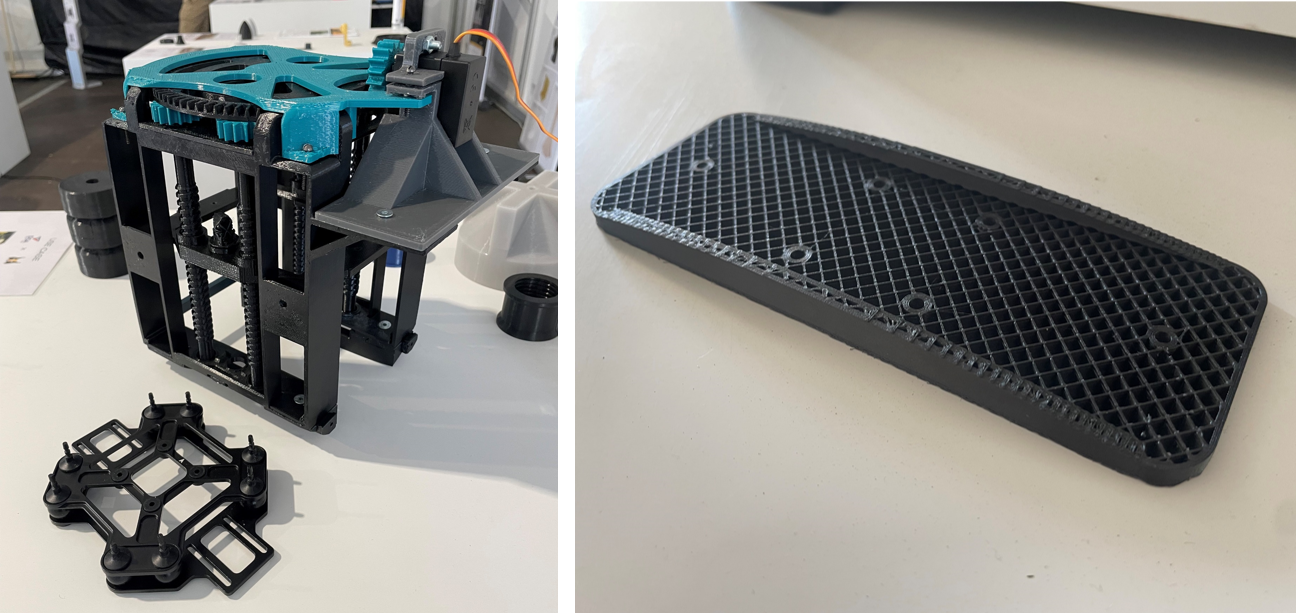

Throughout the event, Lynxter showcased various use cases that were developed in collaboration with prominent defense actors. These included a plug and a silent block in PU for the DGA, a housing case and seal for the SIMMT, as well as a pedal spot and a car door stop for UNAC.

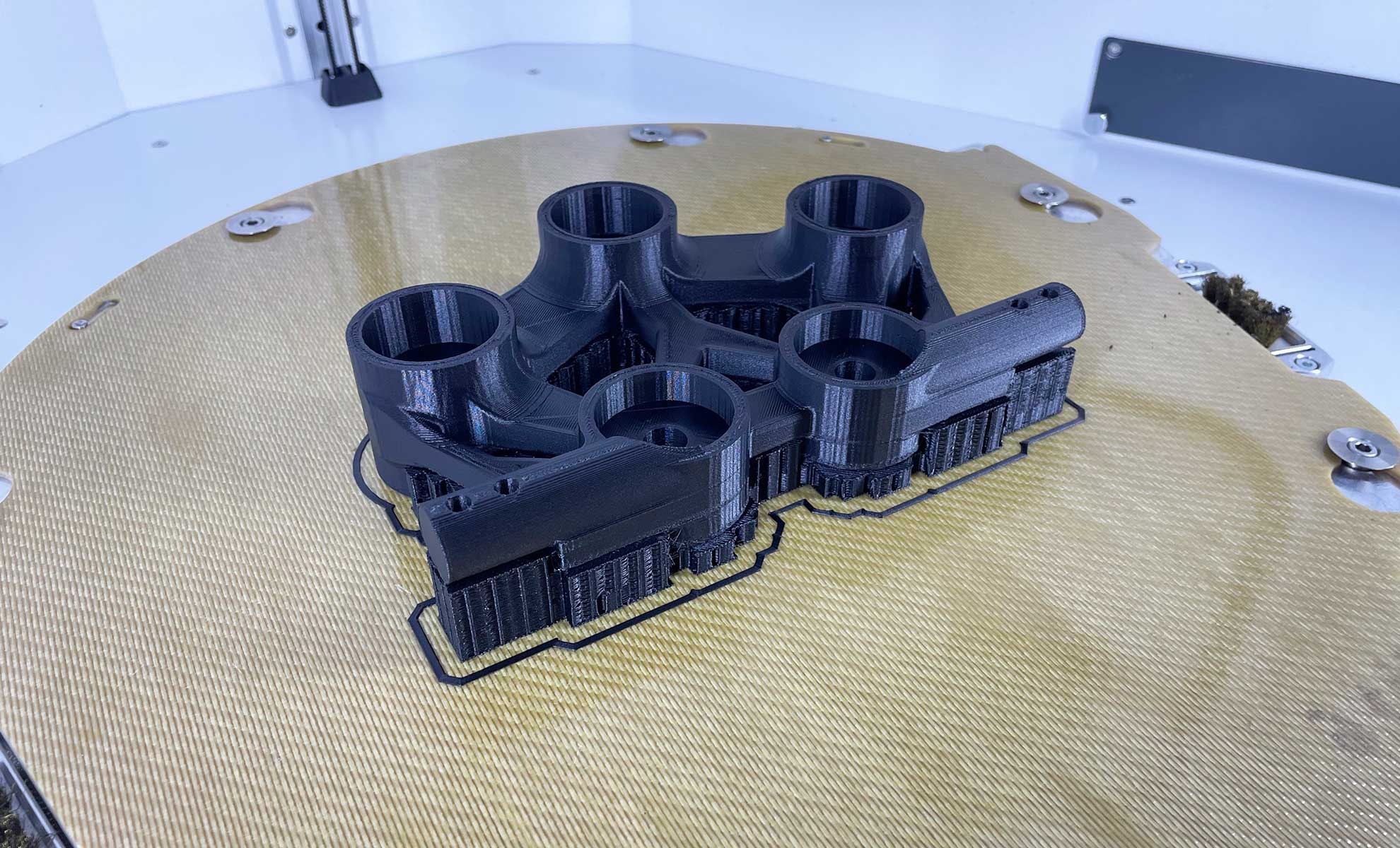

Moreover, the highlight of the AM Village was the live demonstration of Lynxter’s 3D printers: the S600D and S300X. These printers were actively utilized to showcase the versatility and capabilities of 3D printing in diverse defense industry applications presented during the event:

Door ‘s stop – UNAC

Technology and material: S600D or S300X – FIL21 – PU -Time and weight: 2h – 70g

Case + seal – SIMMT

Technology and material: S600D- FIL21 – SIL-001 + PACF -Time and weight: 8h and 70g(case) 8 min and 1,5g (seal)

Drone accessory – Czech Republic

Technology and material: S600D – FIL21 – PA-001 -Time and weight: 1h22 – 20g

Robot joint – Finland

Technology and material: S600D – FIL21 – PA-001 – Time and weight: 20h10 – 240g

Night vision google eyes cushions – Spain

Technology and material: S300X – SIL-001 & SUP-001 -Time and weight: 0h55 – 17g

Long range infrared binocular protection – France

Technology and material: S300X – SIL-001 & SUP-001 – Time and weight: 6h10 – 112g

Welding rod packaging cap

Welding rod packaging capTechnology and material: S300X – SIL-001 – Time and weight: 0h56 – 18g

At the AM Village 2023 event, Lynxter showcased collaborative use cases with prominent defense actors, demonstrating the capabilities of their 3D printers. Modular 3D printing proves valuable in meeting specific military needs, minimizing downtime, and optimizing operational effectiveness in the defense sector.

Want to learn more about this matter?

Contact our team