Symbiosis between silicone 3D printing and textiles

IMAGINE. CREATE. PRINT.

Lynxter Silicone 3D technology gives the material a mysterious delicacy as well as surprising robustness: a major innovation for the design industry.

Of course, we think of luggage, fashion (both haute couture and ready-to-wear) but not only… we also envision applications in the automotive or aerospace industries with personalized seats or those with better vibration absorption. In the medical field, we already imagine the bandages of tomorrow, in sports we improve accessories (silicone reinforcements on knee pads to improve durability and comfort, for example). Let’s not forget the film and entertainment industry with incredible prospects for creating unique sets and never-before-seen props.

There are numerous applications for printing on textiles, and the possibilities are limitless. Especially with our S300X – LIQ21 | LIQ11 machine, silicone printing allows for two applications:

Process 1: The machine directly prints silicone onto an existing textile piece.

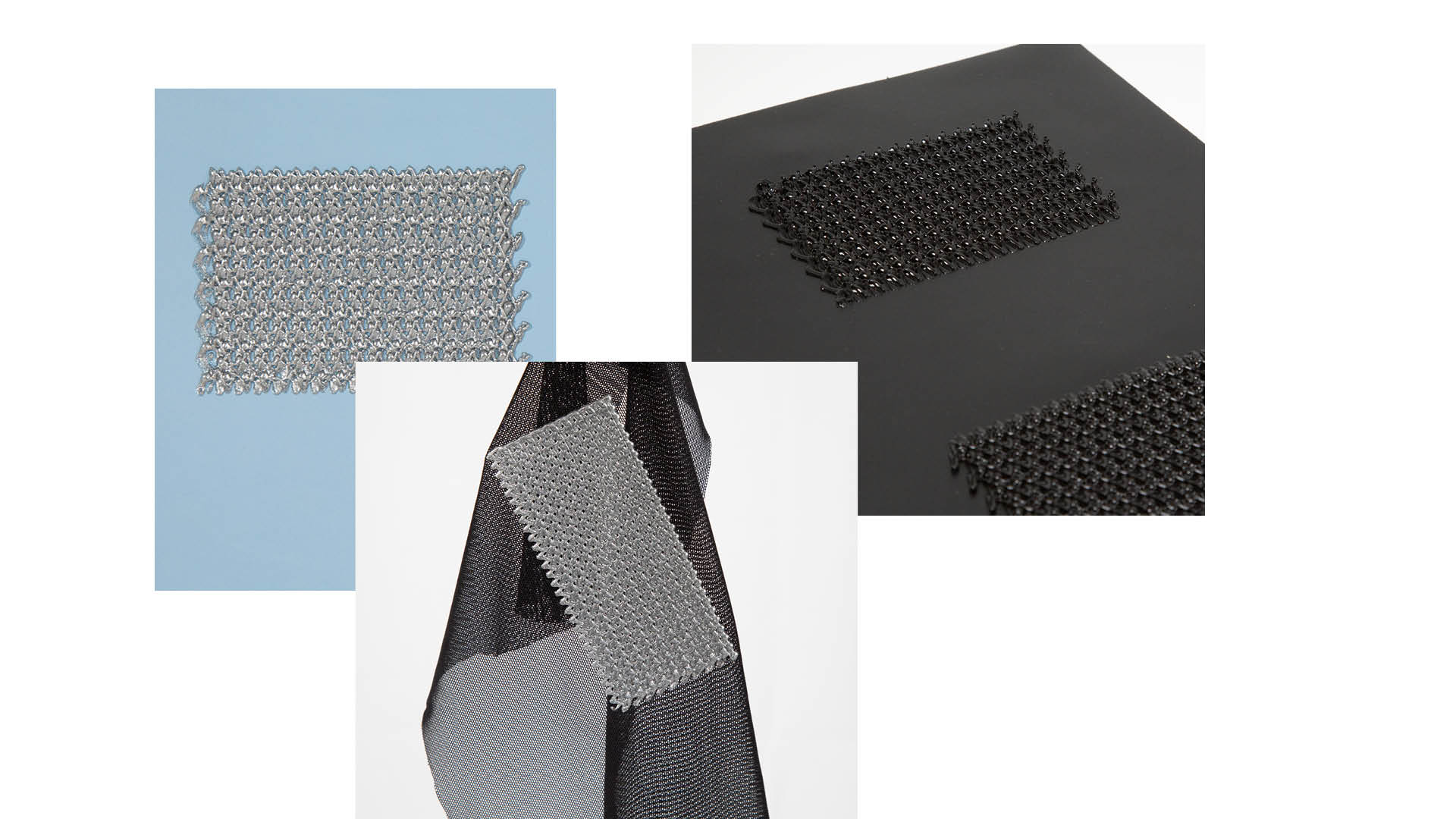

Process 2: The silicone itself becomes a “textile” material.

Textures, patterns, fabrics, electric colors, straw yellow or petrol blue, multi-colored glitter integrated into silicone—the possibilities are endless, limited only by your imagination.

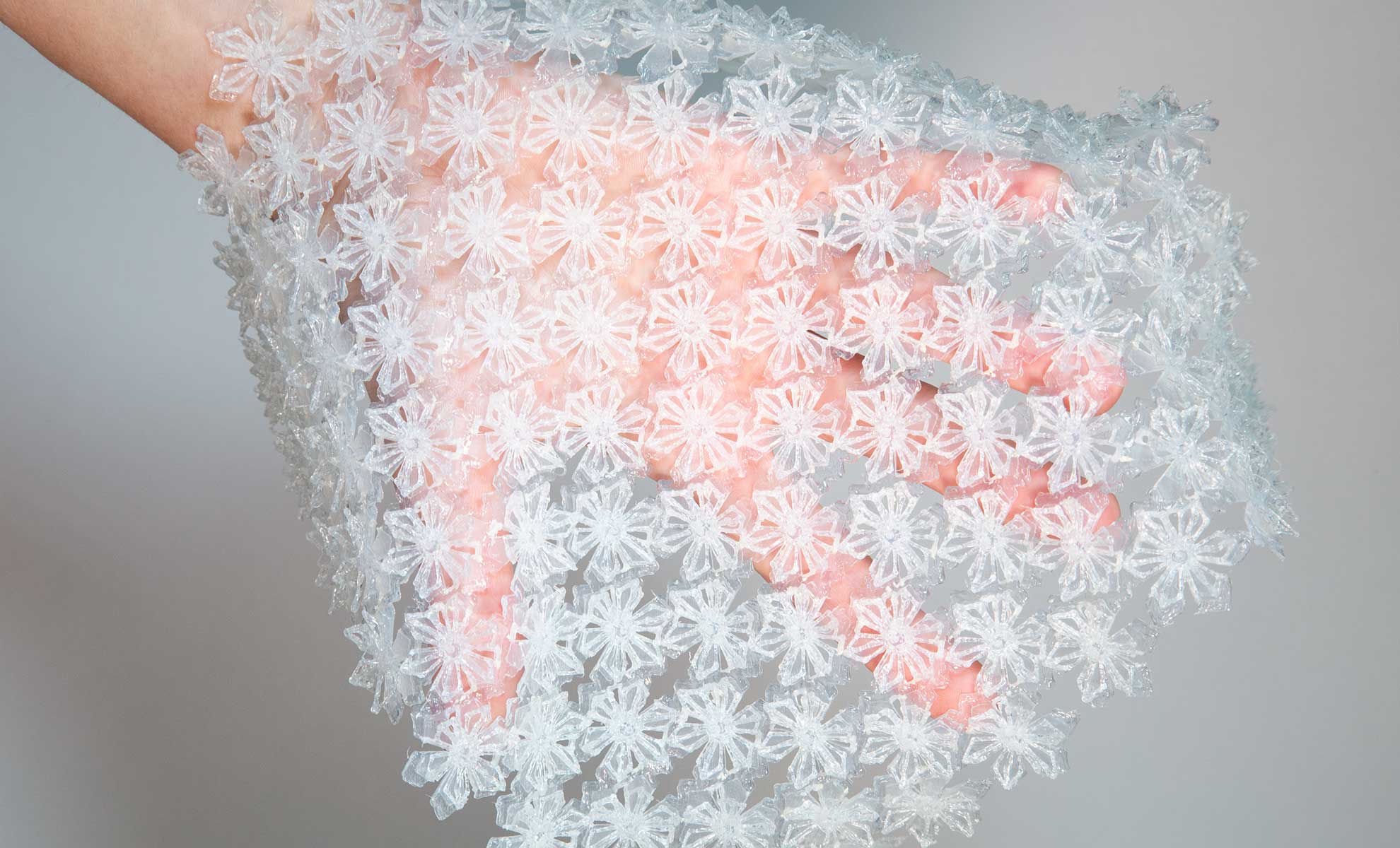

3D printing of silicone flowers in transparency

APPLICATION CASE: INCXNNUE x LYNXTER

When we talk about innovation, we appreciate information, details, explanations, and possible applications. We invite you to dive into this fusion between silicone 3D printing and textiles with this example of silicone flower printing applied to the design of a fashion accessory: a women’s handbag. This bag is co-designed with Laura, the designer of the Incxnnue brand. We encourage you to read our previous article for those who are not yet familiar with her (link).

Explore the process

We process the widest range of materials possible on a 3D printing system thanks to a collection of unique technological modules. We shape these materials by changing their state and extruding them through a precise nozzle moving in a multi-axis space. To change their physical state, we use mixing, heat, or humidity as needed. It’s called M.E.X. (Material Extrusion).

With the S300X – LIQ21 | LIQ11, we affirm our expertise in elastic 3D printing, in this specific case, silicone.

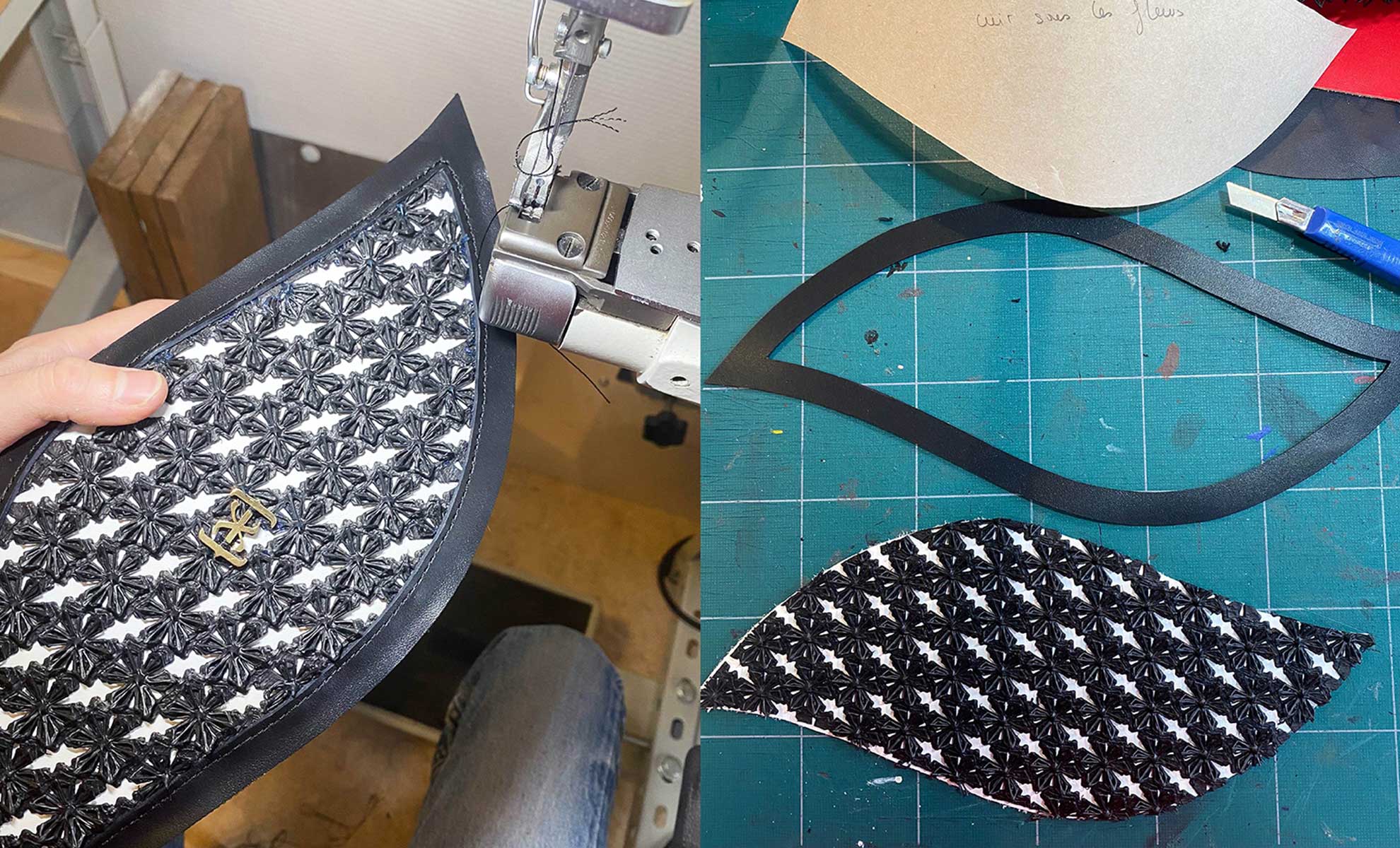

Silicone 3D printing of flowers on the Galaxy clutch bag from Incxnnue

Step 1: Printing

Step 2: Cleaning of support material

Step 3: Assembly

Unleash your inspirations

This new dialogue between creation and technology allows for an innovative approach to design with a very distinctive aesthetic. Leading designers have already begun to “graft” 3D printing into their creative processes, with technology enabling the creation of models with increasingly original and unique shapes. Creativity is freed from the technical constraints imposed by traditional manufacturing methods; the Idex technology of the S300X – LIQ11 | LIQ21 from Lynxter allows unmatched design freedom and infinite formal possibilities.

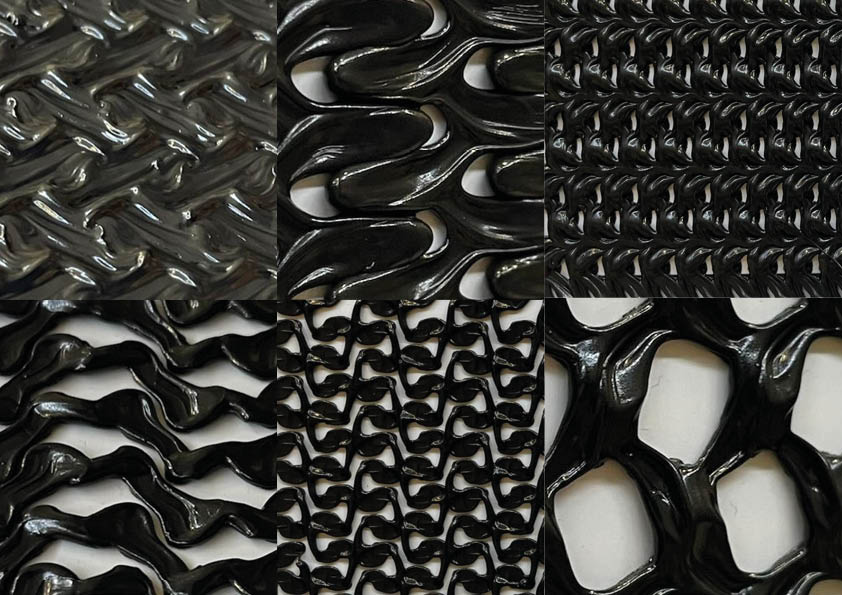

Different printed patterns in silicone

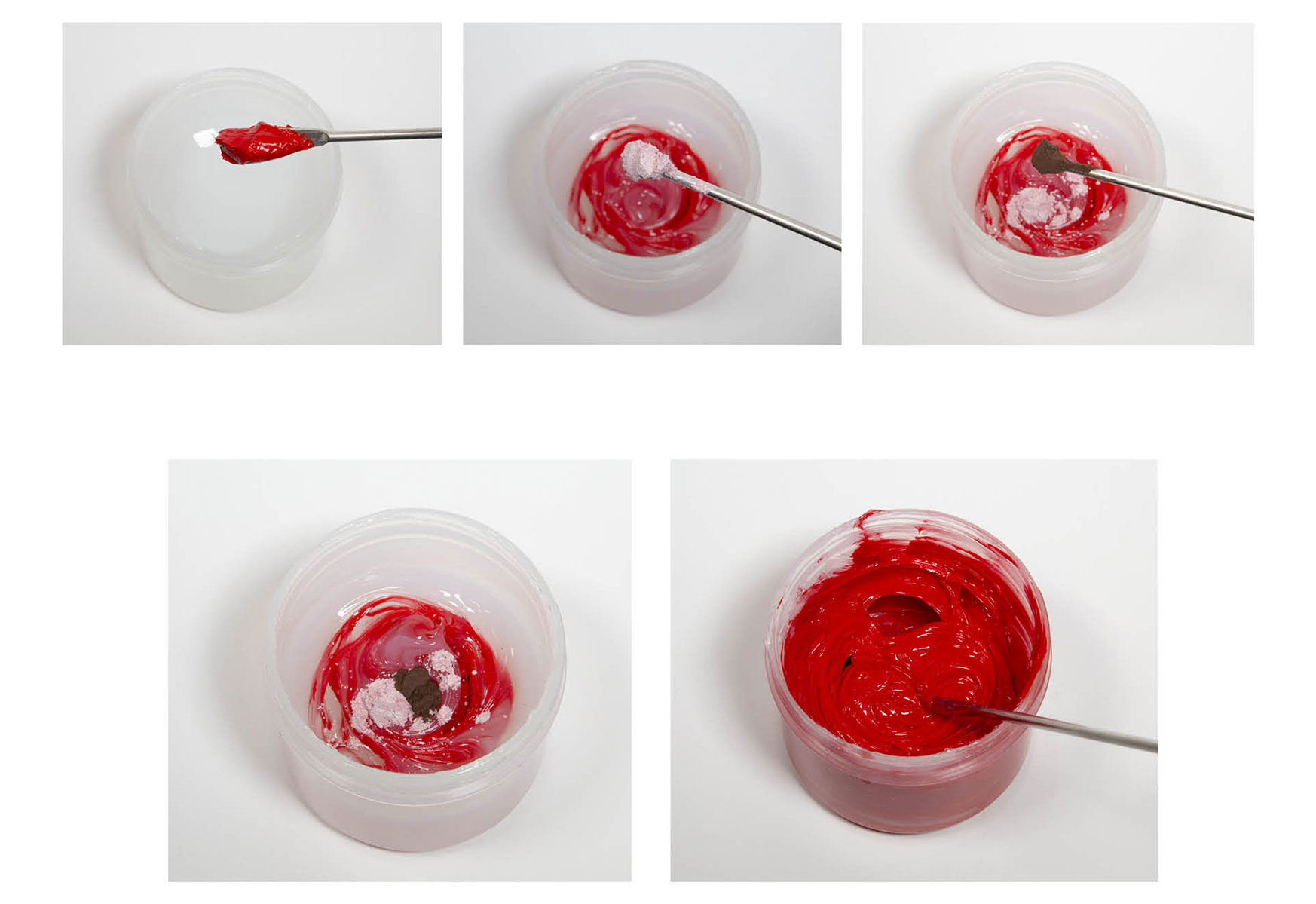

Color your silicone directly and benefit from an infinite and unique color palette according to your inspiration. We recommend using a planetary mixer for optimal homogenization and degassing, without cleaning or loss. Transferring the mixing pot to the syringe is simple and quick, allowing you to directly print your customized materials on the S300X – LIQ 21 | LIQ11. It is also possible to print your design in transparent color and dye it once the printing is done.

Coloring of silicone

Optimize productivity

Before printing, integrate your designs into the software. Make any necessary modifications with detailed views of the model.

The S300X – LIQ21 | LIQ11 has a print surface of 300 x 250 x 200mm. It has an interchangeable platform. This allows for quick switching from one print to another to optimize production time. Similarly, the high-capacity materials option means you can load your silicone and print all your designs, avoiding downtime related to material reloading.

3D printing of silicone flowers with soluble support

Immerse yourself in the technology

Unlike traditional 3D printing, which could be better called 2.5D printing, we do not necessarily stack flat layers. Instead, we offer non-linear additive manufacturing with which we can even play on existing surfaces. Powered by proprietary software, the result is absolutely unprecedented, of an absolutely new beauty. The material flow is part of the design, the depth and complexity of the textures are breathtaking and cannot be achieved with any other technology available to date.

Printing is done on any type of substrate: leather, cotton, nylon, etc. Adhesion is perfect. For this, it is important to combine the materials to check if they are compatible. When they are well matched, the print securely attaches to the substrate surface. You can also directly print a silicone texture to create the material needed to make a garment.

Silicone 3D printing on leather and on Polyamide with Lycra

Our material is suitable for skin contact applications, with formulations developed for the healthcare industry (orthoses, implants, etc.). You can directly put the 3D printed textile in contact with the skin without any harmful effects. Silicone, due to its properties of robustness and sealing, faces no constraints in its use for applications exposed to external constraints (rain, heat, etc.).

Industrial and medical grade silicones (RTV1, RTV2, LSR, …), polyurethanes, hydrogels, inks… we can adapt endless formulations to meet specific requirements, from color and fillers to rheology or specific reactivity. We can bio-source, design recyclable materials, and respect strict HSE constraints for the user.

3D printing of red silicone flowers

Create consciously

3D printing encourages thoughtful manufacturing by eliminating unnecessary waste and surplus. Second-hand clothes and accessories can be customized with the addition of 3D elements. 3D printing also responds to responsible consumption. By internalizing production, creators innovate and design complex and unique designs, leaving aside the polluting complexity of supply chains.

Collaboration with Incxnnue

Laura Deweilde, creator of the Incxnnue brand, deepens her expertise with style and panache by combining sewing and 3D printing. Her bags, co-developed with Thomas Batigne, CEO of Lynxter, seen and now recognized in the series “Emily in Paris,” are already victims of their success.

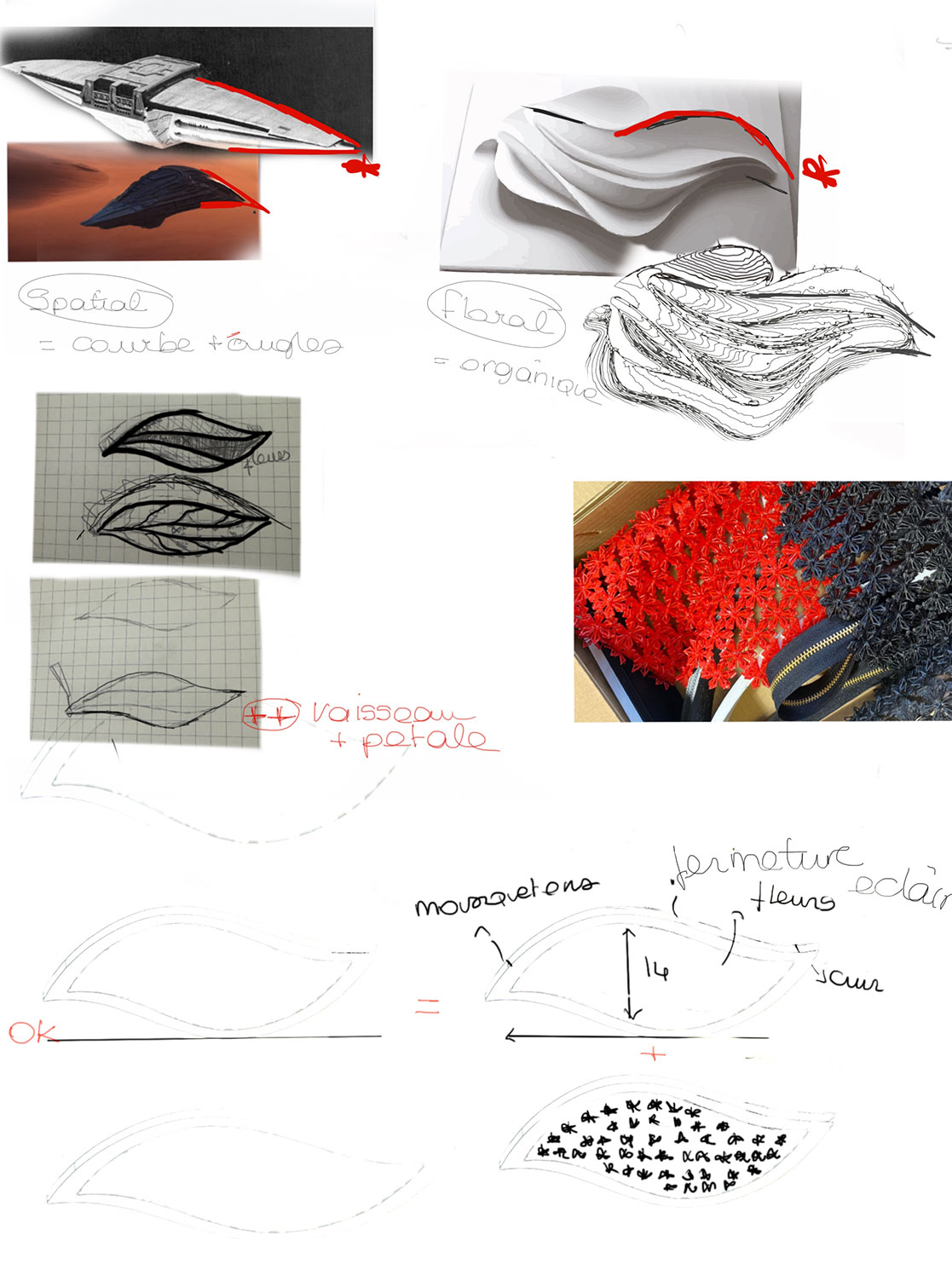

Moodboard of the Galaxy bag by Laura Deweilde from Incxnnue

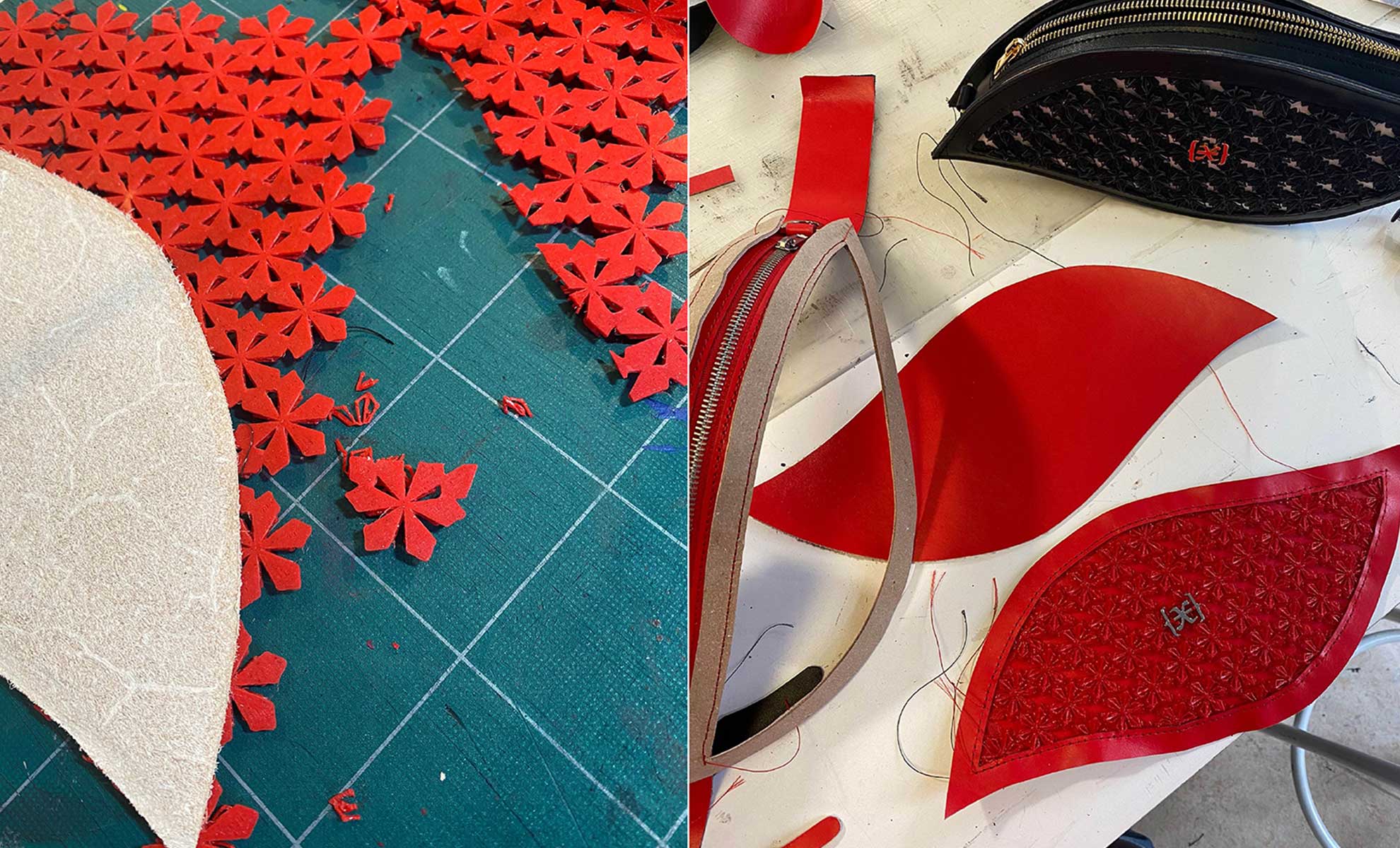

Making of the Galaxy bag in red

Making of the Galaxy bag in black

Here are a few words from Laura Deweilde regarding her latest creation: “For this new creation, the idea was to work on more organic forms with floral inspiration. Thinking back to a floral pattern that I had already modeled, I wanted to go further in terms of creativity and experimentation. By collaborating with Thomas, we were able to transform this exciting and innovative project. With Lynxter, merging organic design with a purer and more architectural form was a beautiful challenge successfully met for this creation, with, notably, a post-search and a studied assembly of this new bag.”

New Galaxy bag from Incxnnue

Laura collaborates daily with the company Teintures de France, equipped with S300X – LIQ21 | LIQ11 machines, with whom we have many ongoing projects.

About Lynxter Studio

We have created a space to allow avant-garde creators to access and play with our laboratory technologies: the Studio. As an OEM (Original Equipment Manufacturer), we design and create many systems, explore new processes and materials. However, market conditions do not necessarily allow all these innovations to be accessible to the general public. We believe that they should not die in a laboratory but rather be shared and be a source of creation, fueled by our scientists and engineers, to be exploited by artists.

Reach out to Lynxter for further insights into our research and use cases.

DOWNLOAD THE WHITE PAPER

Download now “Improve your workflow with silicone 3D printing”.

Discover how this new technology can enhance your productivity and innovation.

Don’t miss this opportunity to gain a new competitive advantage.