Recap of Lynxter’s Open Day: Understanding Everything About Silicone 3D Printing

On Thursday, April 11th, Lynxter held its Open Day, an opportunity to invite its network and partners to explain the adoption of 3D printing in business and the use of silicone 3D printing in different sectors to improve manufacturing processes. The day began with a series of morning conferences, where select speakers presented their expertise in industrial 3D printing, medical applications, and fashion. The afternoon was dedicated to live demonstrations through concrete examples: one group focused on surface treatment and the other on medical applications with the printing of a silicone sleeve, thus putting into practice the printing of specific applications and the use of the S300X silicone 3D printer S300X. The day concluded with a guided tour and personalized appointments to discuss individual projects. The morning was particularly rich in knowledge and sharing. Here’s a summary of the main discussions during these conferences:

Pierre Diaz from Addimadour

Integration of 3D Printing into an Industrial Platform

by Pierre Diaz, Additive Manufacturing Study Engineer at Addimadour

Objective: Explain how to adopt 3D printing in a company by creating an industrial platform for technological sharing.

Current issue: Some companies lack technical or human resources to integrate 3D printing into their production processes.

Proposed solution: Drawing inspiration from platforms such as Turbolab in Bayonne and Xibetek in Mauléon, Pierre Diaz showed how combining the expertise of different companies accelerates the adoption of new processes and technologies, and thus the transformation of companies. The key steps to create these platforms are mastering the technology, understanding the limitations and developing design rules, as well as training personnel in these new technologies to understand their potential.

Martin Lansard from Aniwaa

Silicone 3D Printing: Actors and Processes

by Martin Lansard, co-founder of Aniwaa

Objective: Present the actors in silicone additive manufacturing and their areas of activity.

Current issue: Silicone 3D printing is still relatively unknown. Not all manufacturers offer the same solutions, which sometimes makes understanding difficult.

Summary: In 2024, there are few actors in silicone 3D printing, about ten using MEX technology like Lynxter and 3D Deus Dynamics, and a few using VPP technology. It is important to compare the processes to understand that these two technologies do not offer the same results or functions.

Géraldine Gagnevin from COP

Rethinking External Prosthetic Appliances through Silicone 3D Printing

by Géraldine Gagnevin, Sales Development at COP Chimie x Marc Souply, Founder of MakeSense

Objective: Rethink external orthopedic appliances through silicone 3D printing.

Current issue: Fixed pricing since 2017, artisanal production facing inflation, increasing regulatory requirements, obsolete training, and demotivation among professionals.

Proposed solution: Use digital technology and silicone 3D printing to improve the production process with significant benefits such as reduced production times, better acceptability for the patient, the use of bio-sourced and responsible materials, and compatibility with existing production processes.

Julien Barthes from 3Deus Dynamics

Transforming Industries: The Impact of Silicone 3D Printing

by Julien Barthes from 3Deus Dynamics

Objective: Integrate 3D printing technology through dynamic molding into various applications, including medical and industrial.

Current issue: Limitations of traditional 3D printing due to material compatibility, high R&D costs, and regulatory validation.

Proposed solution: Use multi-patented dynamic molding processes offering design freedom, modulation of mechanical properties, and functionalization freedom. Julien Barthes demonstrated examples of use in surgical simulation, medical devices, and industrial application.

Damien Pomarede from APS Coatings

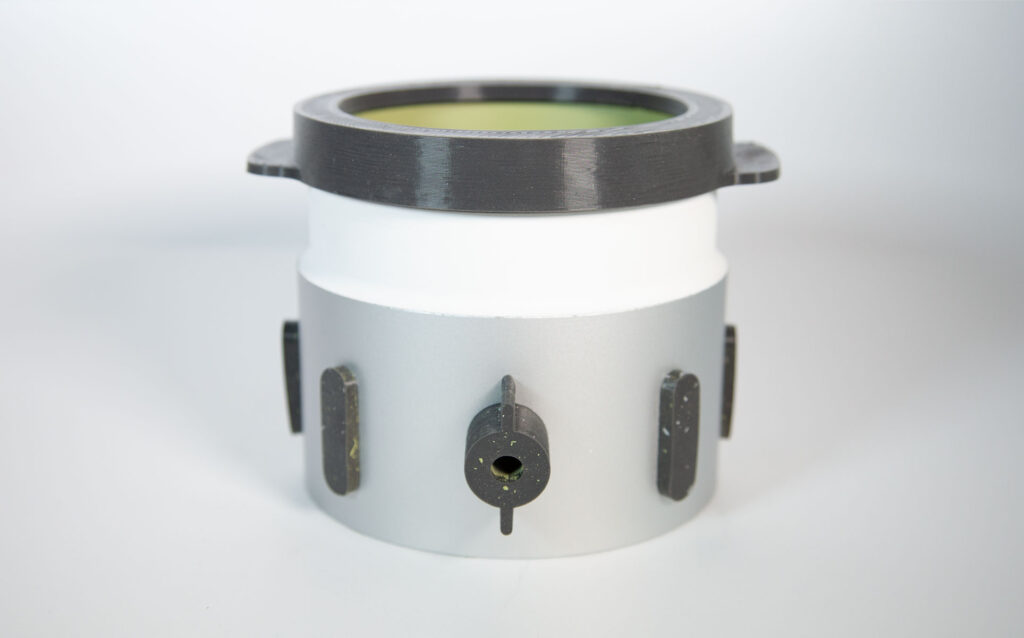

Integration of Silicone 3D Printing Process in the Design of Masking Tools for Surface Treatments

by Damien Pomarede from APS Coatings

Objective: Use 3D printing to create masking tools for surface treatments.

Current issue: High time and costs in the development of masking tools. Current solutions are manual with risks of errors and non-quality, as well as technical constraints in masking.

Proposed solution: Integration of silicone 3D printing for the production of reusable masking tools, resulting in reduced masking and demasking times, improved quality and repeatability, and reduced errors.

Laura Deweilde from Incxnnue

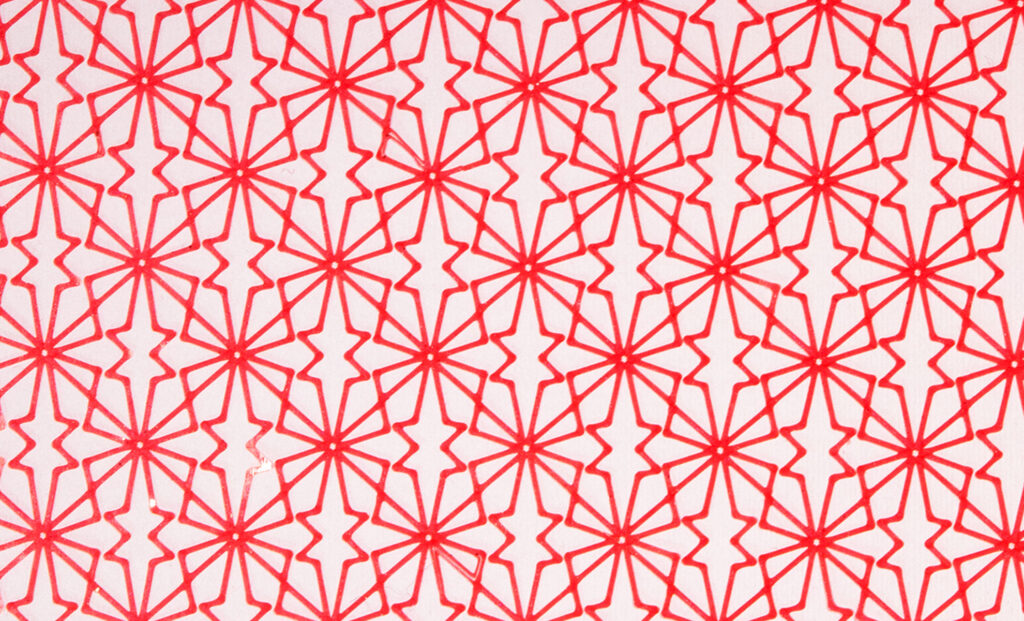

How is Silicone 3D Printing a Vector of Creativity for Fashion and Textiles?

by Laura Deweilde, Founder of Incxnnue

Objective: Explore the creative possibilities of silicone 3D printing in the fashion and textile industry.

Advantages: Offers limitless creative freedom in terms of design, flexibility, texture, and color. Silicone prints on many textiles.

Opportunities: Using silicone 3D printing as a vector of creativity to experiment with new concepts and to develop local production with a short supply cycle.

Thomas Batigne from Lynxter

Medical application case workshop with Adeline Aubin, Brice Parilusyan, and Marc Souply via video

Industrial application case workshop with Antonin Petit-Brisson and Corentin Petit

Lynxter’s Open Days were an event rich in insights and exchanges, providing a comprehensive view of the impact and applications of silicone 3D printing in various fields. From integrating this technology into industrial processes to its innovative use in the design of medical devices and surface tools, and its creative implications in the fashion and textile industry, the discussions highlighted the growing importance of this technology in our modern world. By fostering collaboration among actors from different sectors and highlighting the benefits and opportunities offered by silicone 3D printing, this event contributed to catalyzing innovation and stimulating the transformation of many industries. Lynxter is delighted to have shared this enriching experience with its partners and network and is ready to continue developing the endless possibilities offered by this exciting technology.

Would you like to learn more about this event and the content of the conferences? Contact our teams to get all the details.