Cool Upcyling

We manufacture 3D printing machines. We print parts using various materials, with expertise in elastomeric printing. We sell our solution. To promote this production, we are developing tools for our sales representatives, resellers, and distributors to diffuse this expertise.

In this approach, we came up with the idea of reusing the banners from our events, which we have carefully stored, to create a kit. The idea is to put 3D printed demonstration pieces made with our S600D and S300X-LIQ11|LIQ21 machines inside the kit.

Trade show banners for formnext 2022

The brand identity conveyed by a company at an event makes a difference. We invest in high-quality materials that we reuse from one trade show to another, from one year to the next. Then technology evolves, messages change. It should be noted that our R&D department is in constant motion. We innovate. It’s our core activity.

We print a new updated visual.

Since 2016, we have been holding onto these materials. Six years of trade shows equals several square meters of banners. Tony, our production manager, is fully aware of this. We know there’s something to be done. Tote bags, hammocks, kite-surfing sails, beach bags… ideas abound. We were lacking a purposeful and meaningful use. Time passes, priorities evolve. Naturally. And of course, we needed a container for our demonstration pieces.

Then we meet Antoine and his team from Zanzibar. They immerse us in the reality of the project. Preconceptions vanish, complexity fades away. Humanity prevails at the heart of a project with just and real values. In addition to the ecological added value, the production cost is also more than competitive compared to buying a new kit.

We’ve decided to tell you about this project in detail, hoping it will be inspiring for many actors in the sector and beyond.

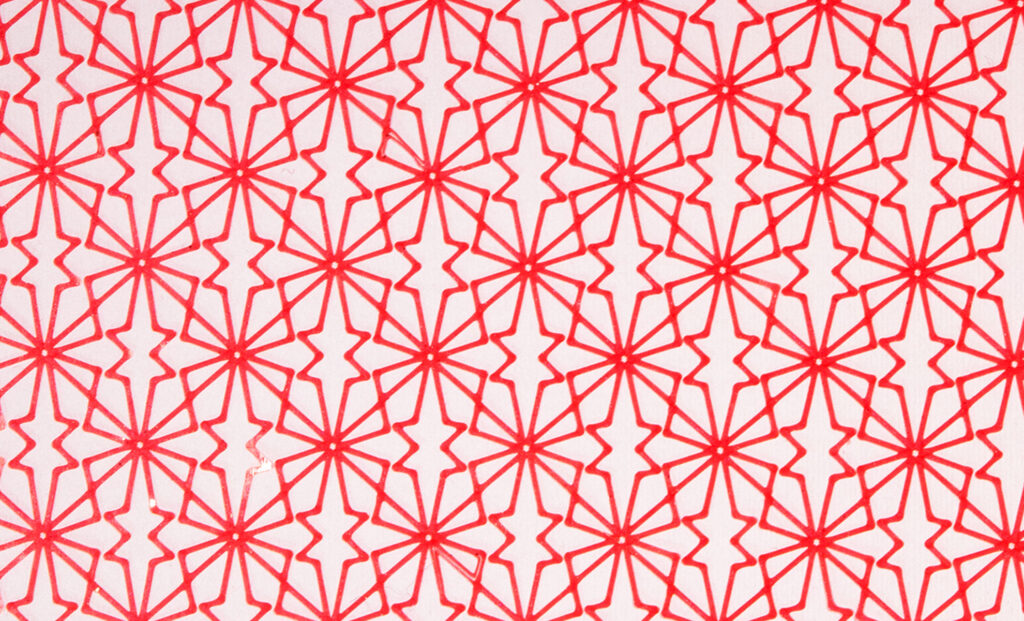

Lynxter pouch pattern

Step 1

First meeting with Antoine from Zanzibar – Project feasibility

Thomas Batigne, CEO of Lynxter, with a creative soul, designed, with his family, the prototype of THE ideal kit. We show it to Antoine, the head of Zanzibar, along with a sample of our banners. What’s fantastic is that for him, it’s feasible. Anything is possible. After exchanging ideas and discussing together, we add a small pocket at the back to insert explanatory sheets for each piece. Then, we decide to include a handle with silicone printed on the banners, so that the object is complete and, while we’re at it, reflects our image.

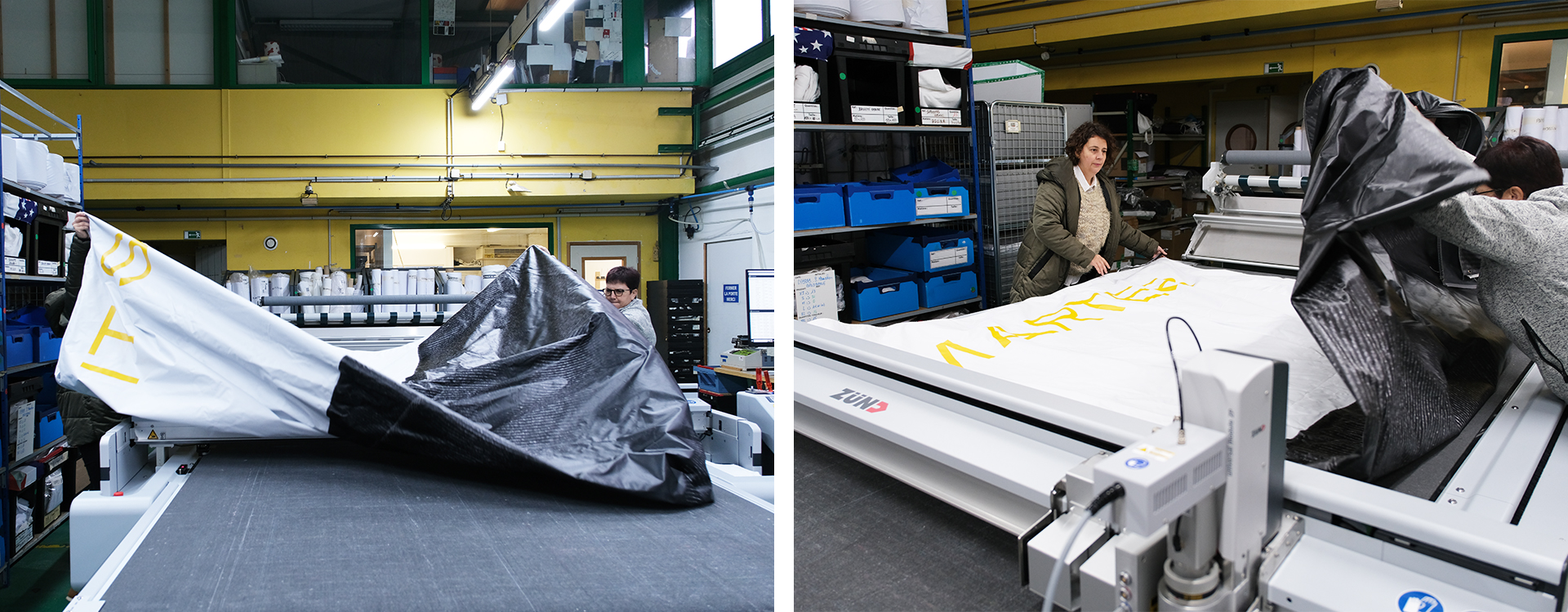

Cutout of the Lynxter pouch

Step 2

Meeting with the team – Production of the pouch

A few weeks later, the project begins to take shape. Caroline, the production manager, welcomes us with a smile into her workshops. We meet her fabulous team: Sylvie, Coco, Corinne, Stide, Sylvette, and Gaëlle, who will guide us through the various stages.

After the prototype is approved, the banners will be cut using a laser machine. The model of our kit, previously registered in the software, is automatically sectioned in series on our large banners. It’s exciting to envision the reuse of this material into a useful object for our teams and partners.

Following that, our beautiful labels will be printed on entirely recycled fabric.

Then, they will be cut on the same machine.

The recycled fabric labels are ready

Step 3

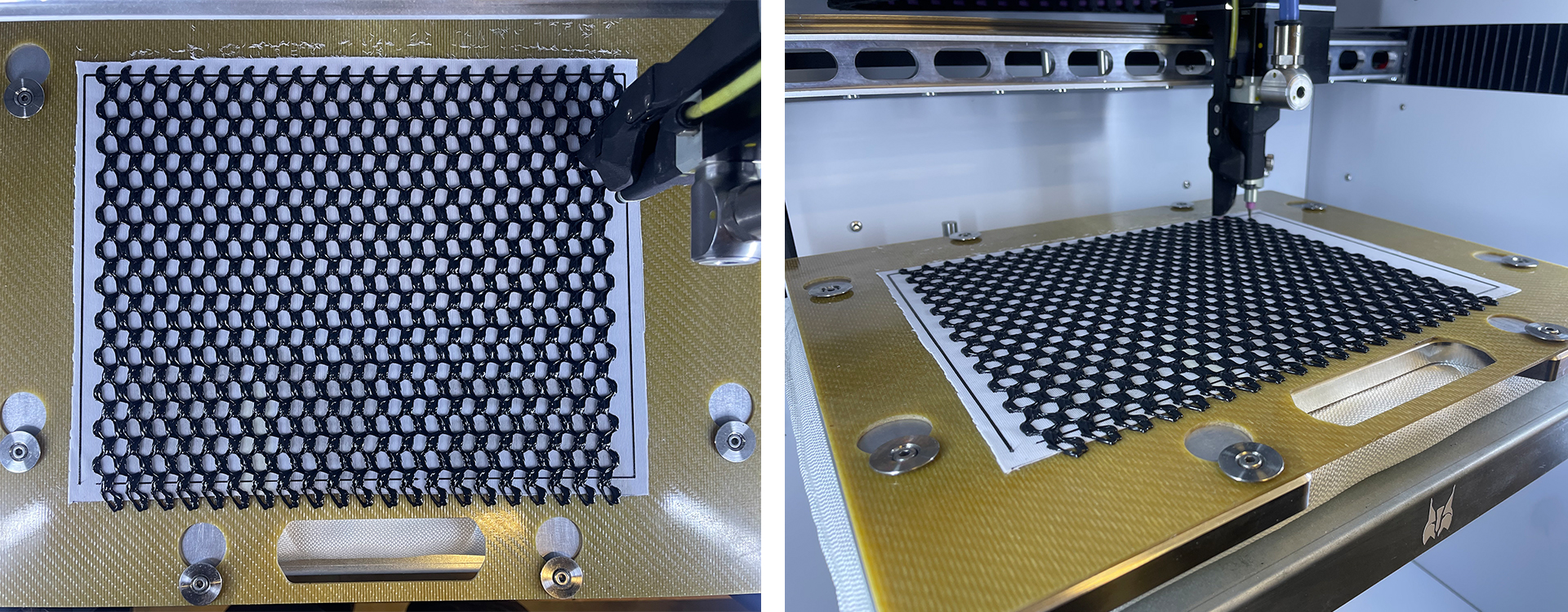

Personalization – 3D Silicone printing on fabric

Meanwhile, Caroline carefully undertakes the cutting of the handles. They perfectly showcase our silicone 3D printing technology on fabric. Yes, we are experts in silicone 3D printing. This is the small touch of “personalization” for the object. It’s important to note that silicone is also printed on the recycled banners.

3D printing of silicone on textile

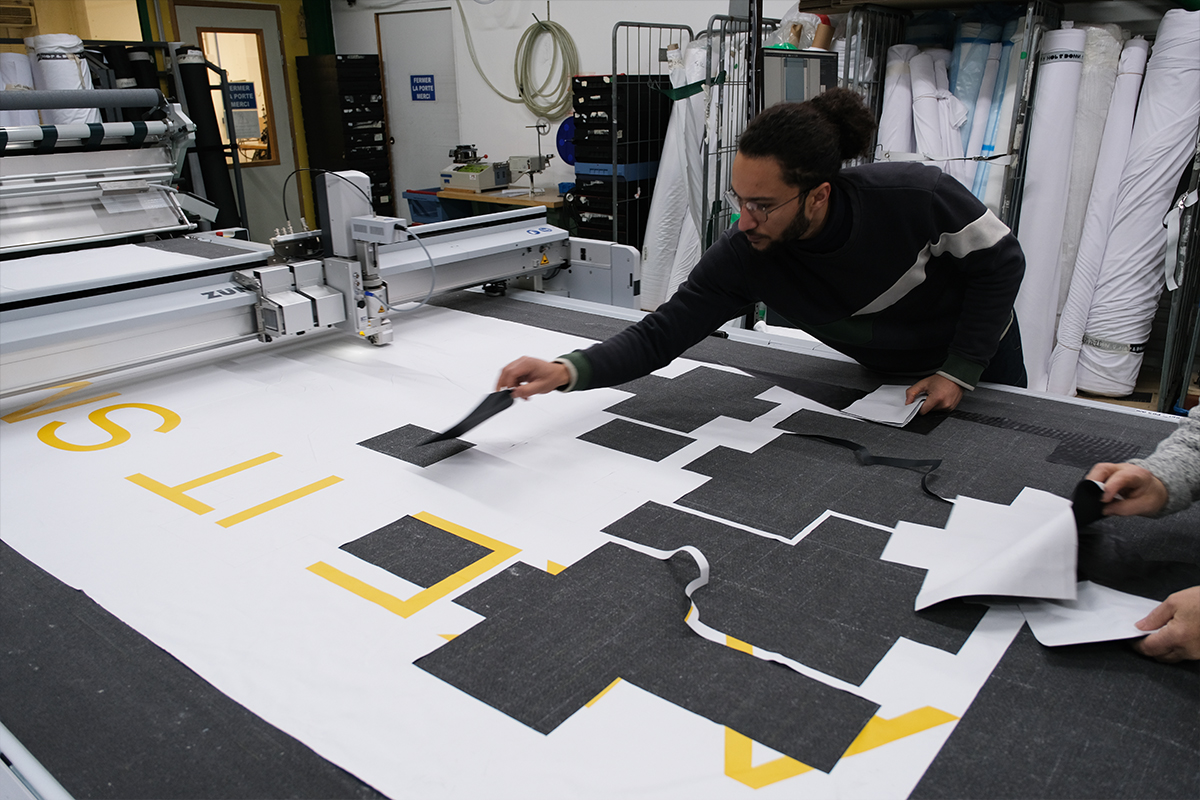

Cutting out the cover pattern on the banners

Step 4

Assembly at the sewing workshop

It’s now Corinne’s turn to take over. Her dexterity will breathe life into the object. A few hours of sewing will be required to assemble all the elements: pouch, label, and handle.

Corinne sews the first Lynxter pouches

Step 5

Using the pouch and new projects

Some pockets for our teams

These pouches now contain our new series of 3D printed demonstration pieces. They will be distributed to all our partners. This kit will travel from professional meeting to professional meeting. Perhaps its function will even evolve. We won’t deny that it would please us.

We are happy to have seen it through to the end. In addition to the human exchanges, there is the satisfaction of consuming less and creating justly. It was a wonderful collaboration with Zanzibar, 100% local, as they are our neighbors. And this will surely not be our last creation together.

About Zanzibar : zanzibar.fr

the pouch will be used by all our resellers to transport the demo parts