LYNXTER, ERPRO AND GACHES CHIMIE PARTNERSHIP

LYNXTER, ERPRO AND GACHES CHIMIE JOIN FORCES FOR SILICONE ADDITIVE MANUFACTURING

Aware that they are stronger together, the three expert enterprises from France have pooled their expertise to propose an innovative and global additive manufacturing solution.

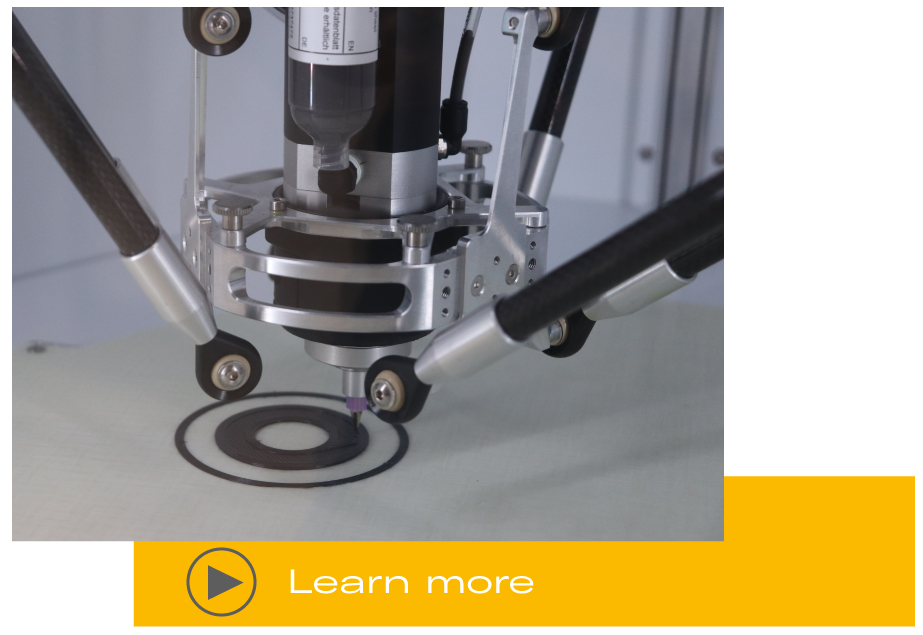

The S600D, modular and open professional 3D printer, is the only additive manufacturing machine on the market that can deposit liquid silicone material (EAM: Extrusion Additive Manufacturing). The Erpro Group, via its subsidiary Silinnov, has acquired the S600D printer and has contributed its expertise in multi-sector additive manufacturing as well as its expert knowledge of silicones. Gaches Chimie, major supplier of chemical products, proposes a wide range of silicones and provides consumables for 3D printing with silicone.

For this partnership, a range of silicones exclusive to 3D printing was developed and configured on the S600D and its liquid toolheads. These industrial high-performance silicones, both single and two-component, meet the needs of various sectors such as luxury, defense, aeronautics, paramedics, education etc.

Individual assistance is provided in parallel to determine which silicone material best matches the application based on the specifications of the part to produce. A range of post-processing and finishing techniques can then be envisaged to perfect the final product.

Silicone additive manufacturing has many advantages:

– REACH compliant chemicals

– Resistance to high temperatures

– Good elongation and tear resistance properties

– A range of hardness levels

– Features for improving resistance in aggressive chemical environments

Additive manufacturing makes it possible to use these materials in small and medium-size series, thus simplifying the ultra-personalization of products on a local level. Moreover, the technical properties of parts manufactured with liquid additive manufacturing (EAM – Extrusion Additive Manufacturing) remain comparable to those made using conventional injection molding processes.

The power of this partnership lies also in its potential to evolve. Lynxter’s S600D can extrude other liquid materials (such as polyurethanes and epoxies) from the comprehensive range proposed by Gaches Chimie. With the Erpro Group’s expertise in multi-material additive manufacturing, these new processes can be perfected and made available to consumers.

This collaboration is therefore a precursor to new innovations in liquid additive manufacturing.

About Silinnov:

Silinnov is part of the French Erpro Group, leader in small, medium and large series production with additive manufacturing. With 40 years of know-how in the implementation of silicones by casting, injection and vulcanization for industries including aeronautics, healthcare, para-medical, surface treatment, pad printing and agri-food industries, Silinnov actively supports with advice and professional expertise.

For more information: erpro-group.com

About Gaches Chimie :

With its 70 years of experience, the Gaches Chimie group proposes a complete range of elastomeric products and services (sourcing, advice, logistic services, training etc.)

The technology developed by LYNXTER enabling silicone to be used a material for 3D printing is a breakthrough for all industries due to the many outstanding properties exhibited by elastomers: high flexibility/elasticity, bio-compatibility, insulator or conductor etc.

For more information: www.gaches.com