LYNXTER SIGNS A RESEARCH CHAIR WITH THE DE VINCI UNIVERSITY CENTER

The De Vinci Innovation Center and Lynxter have decided to work together for a 3 year period via a Research Chair. The aim is to develop new intelligent materials with integrated electronics. This technology will revolutionize the way prostheses, exoskeletons and robotics in general are manufactured.

Lynxter’s goal is to develop the potential of the additive manufacturing sector. Our aim is to encourage creativity and innovation through the transfer of knowledge and technical solutions.Lynxter’s open and modular S600D can be used to print various different high-performance materials (thermoplastics, liquids and pastes). Nonetheless, the association of solid and liquid materials still requires considerable research and development.

The De Vinci Innovation Center (DVIC) is the transdisciplinary center of expertise of the Pôle Léonard de Vinci University Center. The center’s academic programs allow students to explore new methods based on radical and antidisciplinary learning and collective intelligence.

Its “Demo or Die” motto, inherited from the MIT MediaLab, is carried by science, technology and human values, in order to address key challenges in our society.

Open up new opportunities in life through additive manufacturing to those needing prosthetics.

“This collaboration with the De Vinci Engineering School mirrors our values and innovation goals along with those of training and research centers. Moreover, the additive manufacturing sector is booming and this technology must be mastered fully by a new breed of engineers. This partnership enables the implementation of research works of young postgraduates in various sectors that can benefit from its solutions and expertise. The first of the numerous topics to be examined under this partnership is the study of smart materials in additive manufacturing”, said Thomas Batigne, co-founder and president of Lynxter.

“Our students experiment and build smart materials on a daily basis with or without a 3D printer. For example, we have developed a synthetic, multi-layer, artificial skin that includes the dermis, epidermis, veins and a texture capable of mimicking the sense of touch”, added Clément Duhart, head of the De Vinci Innovation Center.

In order to pursue student research, the DVIC has set up a Research Chair with Lynxter to pool resources and explore the benefits of “smart” materials in the field of additive manufacturing.

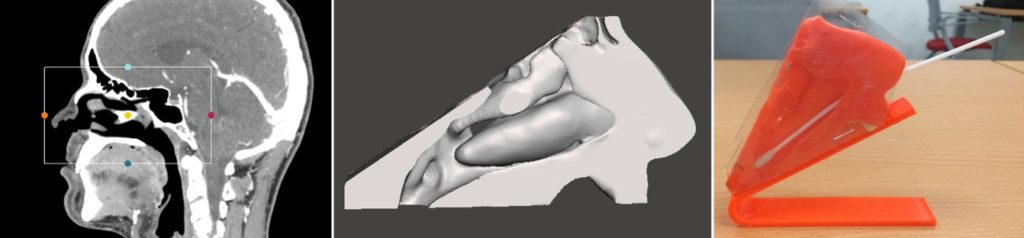

The loss of mobility or the loss of a limb is traumatic for the patient and is usually definitive. Until now, solutions have only been partially developed and are unfinished.

The aim is to use additive manufacturing and its numerous possibilities to offer new solutions to disabled people so that they can regain mobility and their abilities.

Two aspects must be taken into consideration:

– The technical aspect: The creation of a silicone part containing an electronic circuit in one single build can transform prostheses into active, artificial body parts. Feedback is provided by the electronic circuit and the silicone is stretchable, soft and adaptable making it possible to pick up objects.

– The visual aspect: the association of soft materials gives the prostheses a more human appearance, making it easier for the patient to accept them as body parts. Silicone allows the texture, color and the hardness to be modified.

Brice Parilusyn (2021 ESILV graduate and postgraduate at DVIC) is working with Lynxter on this research project. He shares his time between La Défense (Paris) and the Basque region on a regular basis.

“Firstly, we are researching the development of a new generation of prostheses capable of providing touch and feel sensations thanks to a flexible and active technology that will bring new perspectives to disabled people and to robotics. Secondly, we can foresee assisting other areas of research via various partnerships notably in healthcare, education and sport”, confirmed Brice Parilusyan.

To summarize, this research is part of a prostheses development project to mimic the appearance and functions of a human limb.

About the Pôle Léonard de Vinci

The Pôle Léonard de Vinci is a higher education university institution composed of three universities that deliver recognized diplomas in complementary disciplinary fields, notably in the digital sector: a business school, l’EMLV (Ecole de Management Léonard de Vinci), an engineering school, l’ESILV (Ecole Supérieure d’Ingénieurs Léonard de Vinci) and an Internet & Multimedia school, l’IIM (Institut de l’Internet et du Multimédia). The DVRC (De Vinci Research Center) is a research laboratory combining research capabilities from all 3 schools. Founded in 1995, the three schools are located at the Pôle Universitaire Léonard de Vinci university campus in La Défense, Paris, France.Hybridization, professionalization, internationalization, social diversity, sports and corporate culture are values at the heart of the campus. Hybridization is the result of the transversality that exists between the schools: common courses and projects, progressive and intensive development of soft skills, incubator, FabLab etc. Engineers, managers, designers and developers learn to live and work together beyond the boundaries of their individual curriculum.

For more information: www.devinci.fr