3D Printing : Rise of Personalized Medecines

3D printing is shaking up the pharmaceutical industry, bringing a new perspective to its production techniques. Lynxter plays a key role in this innovative momentum by combining its technological expertise with the know-how of the startup MB Therapeutics.Together, they are reshaping this sector by providing a unique solution of personalized 3D printed medicines primarily targeting children.

3D printed medicines with MED-U Modular

3D Printing Medecines becomes a reality

Currently, for certain medications, the pharmaceutical industry does not provide a solution for patients. Pharmacists, therefore, produce medications to fill in this gap. These preparations are typically done manually. 3D printing of medicines provides concrete solutions to various problems:

> Flexibility in customizing medications. This technology offers personalized combinations of molecules with individually adjusted dosages, manufactured for each patient to meet specific needs.

> Improvement in the shape design of pills (adaptation to children: size and acceptance for example). In addition to molecules, additive manufacturing opens up the possibility of modifying the taste profile: revising the aromas of drugs for a more pleasant intake.

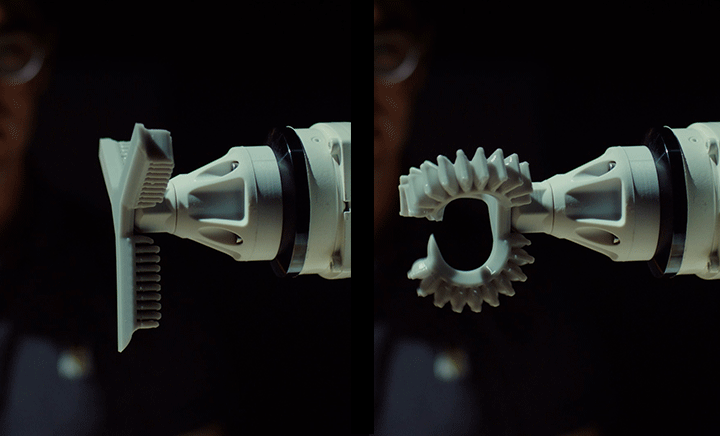

Different shapes of 3D printed medicines with MED-U Modular

> On-demand manufacturing facilitated by the installation of 3D printers in hospital dispensaries and pharmacies leads to a reduction in supply delays and, consequently, an increase in production speed. By decentralizing pharmaceutical production, this solution also provides access to medications in underserved or remote areas.

> Addresses the challenges of polypharmacy by combining multiple medications into a single oral form. Taking several tablets daily can be cumbersome, prone to errors, and may impact the effectiveness of a treatment.

> Possibility to produce small batches for testing purposes in quantities that are not cost-effective for factories or traditional manufacturing processes.

> Automates magistral and hospital preparations.

> Addresses the growing issue of drug shortages.

> On-demand production of medications also significantly reduces waste production (packaging) and intensive wastage.

3D printing of medicines proves to be a precise, reproducible and cost-effective technique to overcome several identified challenges and improve the current supply.

Lynxter participe à cette innovation en apportant son expertise technologique

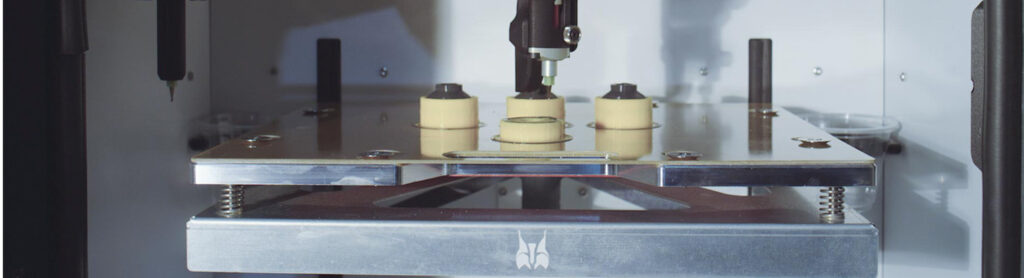

The MED-U Modular printer, co-developed by Lynxter and MB Therapeutics, is designed for 3D printing of medications. Several years of research and development have led to the creation of the MED-U Modular machine, specifically designed for the pharmaceutical industry. Lynxter’s expertise in additive manufacturing of industrial machines is complemented by the know-how of MB Therapeutics, specializing in the production of custom medications.

As its name suggests, the modularity of the MED-U Modular printer allows for the printing of various rheologies, whether in the form of gel or paste, compatible with thermosensitive active ingredients.

This solution provides industrial security while ensuring precision and ease of use.

Lynxter also contributes its expertise to the security of the printing process through the development of secure software that enables traceability of actions.

3D MED-U Modular Pharmaceutical 3D printer

MB therapeutics, projects, and perspectives

MB Therapeutics works closely with healthcare professionals to develop custom drug production solutions for children with diseases. The company believes that the use of 3D printing technology can have a significant impact on the quality of life of children and their families.

“We are delighted to provide innovative solutions to meet patients’ needs for personalized medicine,” stated Stéphane Roulon, co-founder of the company.”

“We know that children have unique medication needs, and we are committed to improving their experience by providing oral forms tailored to their needs.”

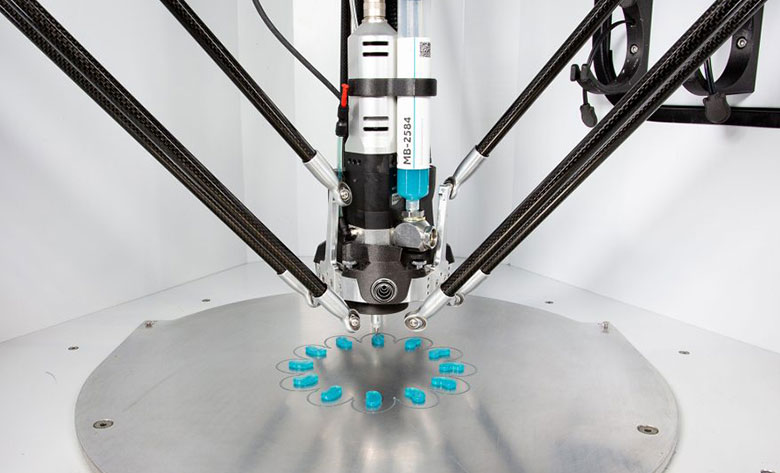

Pharmaceutical 3D Printer MED-U Modular printing drugs

3D printed pediatric medicine

Using 3D printing technology co-developed with the company Lynxter, MB Therapeutics allows the production of personalized oral forms that meet the specific needs of each child. It should be noted that the MB formulation is a safe composition for children. All administrative and qualification processes are approved. There are no excipients with known or contraindicated effects.

Furthermore, the MB Therapeutics solution addresses stock shortages by empowering hospital pharmacies and community pharmacies equipped with a preparation area to produce with industrial quality. This may involve precise dosages and easily ingestible forms.

This established solution is already operational and available.

More information : https://mb-therapeutics.com/

About MB therapeutics

MB Therapeutics is the result of a close collaboration between Lynxter, a recognized manufacturer of industrial 3D printers, Sanofi, and the University Hospital Center (CHU) of Nîmes. Emerging as a startup specializing in personalized medicine and leveraging 3D printing technology, MB Therapeutics is committed to revolutionizing the administration of treatments, especially for young patients affected by various conditions, through its innovation in custom pharmaceutical form manufacturing. This advancement is made in close collaboration with medical experts, showcasing MB Therapeutics’ dedication to health and well-being.

DOWNLOAD THE WHITE PAPER

Download now “Improve your workflow with silicone 3D printing”.

Discover how this new technology can enhance your productivity and innovation.

Don’t miss this opportunity to gain a new competitive advantage.