S300X – LIQ21 | LIQ11: Pushing the Boundaries of Silicone and Polyurethane 3D Printing

Lynxter equips various industries with its S300X – LIQ21 | LIQ11 machine, providing them with a powerful and groundbreaking tool. This technology is designed to elevate production, fostering limitless innovation to enhance profitability, maximize gains, and multiply projects.

S300X – LIQ21 | LIQ11 – Polyurethane and silicone 3D Printer

Optimize prototyping and small to medium-scale production activities with the S300X – LIQ21 | LIQ11, an affordable and high-performance 3D printer. Produce custom mask series for post-processing, shock absorbers, sealing components, certified skin-contact prosthetics and epitheses, and innovative textiles. Print industrial and medical-grade silicones and polyurethanes of exceptional quality.

« We are having fun on our new workshop tool. The machine is well designed and constructed. The IDEX for supports is super ».

Peter de Corte, OMD3D

Today, nothing rivals the S300X – LIQ21 | LIQ11 in terms of its ergonomics, precision, openness, uniqueness, and price. It is the quintessential machine that opens up new horizons

Focus on the Features of the S300X – LIQ21 | LIQ11

Liquid MEX Deposition – High-Quality, Simple, Isotropic Material

The S300X – LIQ21 | LIQ11 enables the rapid 3D printing of parts made up of fine strands of extruded material. These gradually polymerize and crosslink during printing, resulting in a uniform gel-elastic state change, creating isotropic parts comparable to those made through casting or injection molding. The materials used are industrial and medical-grade, free from pollution or degradation due to the process. This approach is innovative in the field and significantly extends the boundaries of known elastomeric 3D printing, particularly through layer-by-layer photopolymerization or extrusion with crosslinking.

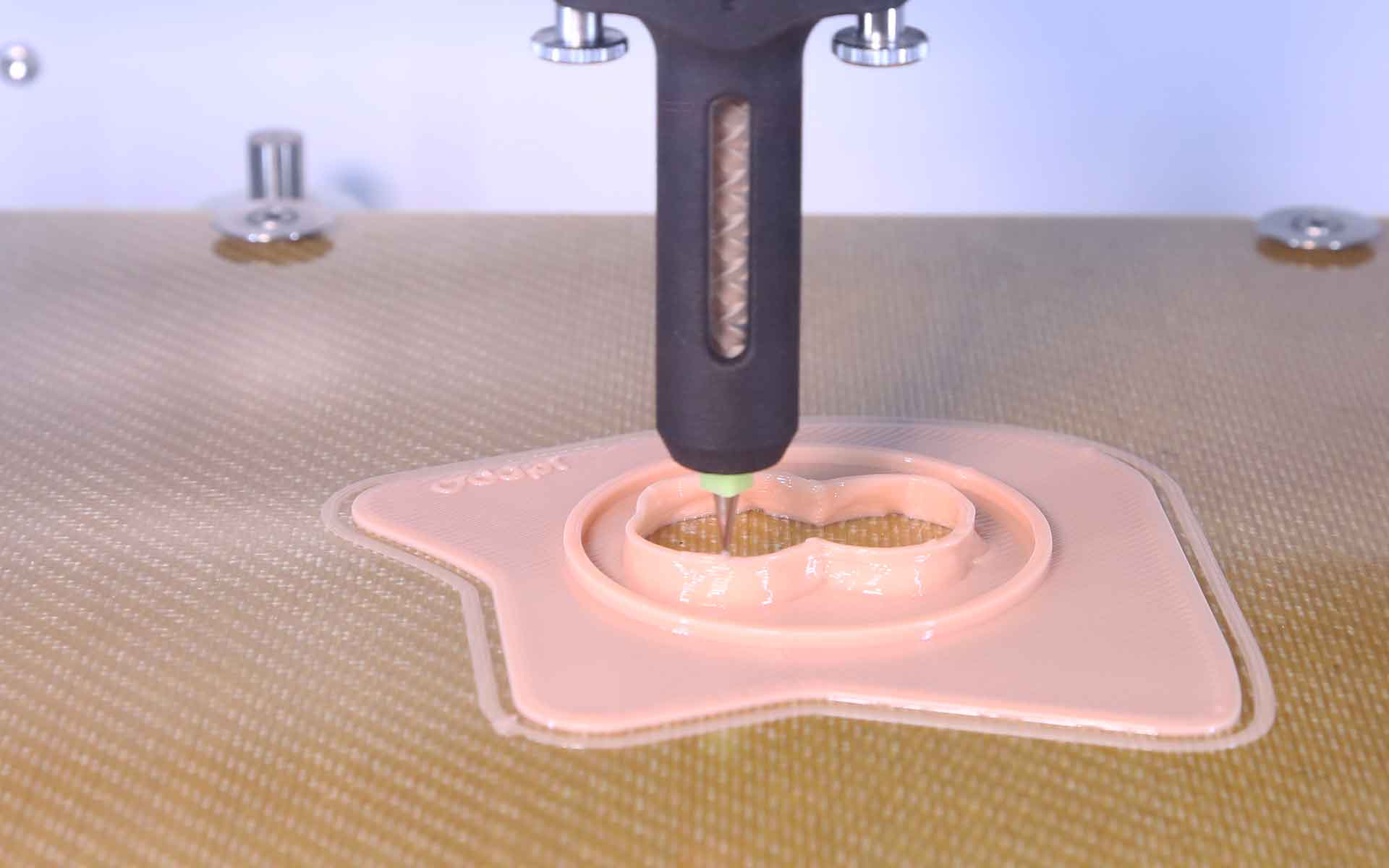

3D Printing a complex-shaped silicone part with support using IDEX technology

IDEX Technology

The S300X – LIQ21 | LIQ11 is designed with IDEX technology, featuring dual extrusion capabilities through the integration of two independent heads: the LIQ21 for extruding two-component materials and the LIQ11 for single-component materials, specifically support material that is entirely soluble. With this technology, forget about shape constraints and print complex geometries with complete freedom.

LIQ21 and LIQ11 toolheads in IDEX configuration

Optimal Materials

Print industrial and medical-grade silicone and polyurethane materials (skin-contact certified) that are both user-friendly and high-performing, with heat resistance, chemical resistance, flexibility, and elasticity. All these advantages make silicone and PU versatile materials used in various applications. The printed parts adapt to demanding environments and possess excellent mechanical, thermal, and chemical properties. In summary, produce robust and functional parts right out of the machine, using materials previously inaccessible in additive manufacturing.

Lynxter develops its own range of silicones and polyurethanes (SIL-001, SUP-001…) for effortless printing. Note that the machine’s openness allows for printing all types of liquids and gels.

Small and Large Capacity

There are two material packaging options for the S300X – LIQ21 | LIQ11: the small syringe (55cc) or the large cartridge (750cc). Syringes are perfectly suited for low consumption, expensive material, or discovering new references. Opt for the large capacity for production, printing large parts, or achieving economies of scale. Easily switch between small and large capacity with a set of accessories.

The S300X can integrate 750 cc silicone and support cartridges

Accessible to All

The S300X – LIQ21 | LIQ11 offers the ability to print certified Lynxter materials, but the entire ecosystem remains open for use. Configuring and printing with other materials is possible. This flexibility allows for exploring and adapting the properties of silicones or polyurethanes for specific projects. Dimensionally, the machine measures W 991 x L 720 x H 985 mm and weighs 135 kg, making it a compact format that fits perfectly on a workbench. Its price and ease of use make the S300X – LIQ21 | LIQ11 accessible to businesses of all sizes.

An Asset for Multiple Sectors

R&D, aerospace, maintenance, medical: the ability of the S300X – LIQ21 | LIQ11 to produce complex, customized, high-quality parts meets various needs and encompasses significant applications. For example, custom and reusable masking solutions in the aerospace industry. The medical sector is revolutionized by the possibility of printing customized epitheses, prostheses, and other medical devices using qualified materials. R&D centers benefit from a new open platform for developing 3D printed thermosetting applications. The textile industry is reinvented through volume printing directly on fabrics or leather.

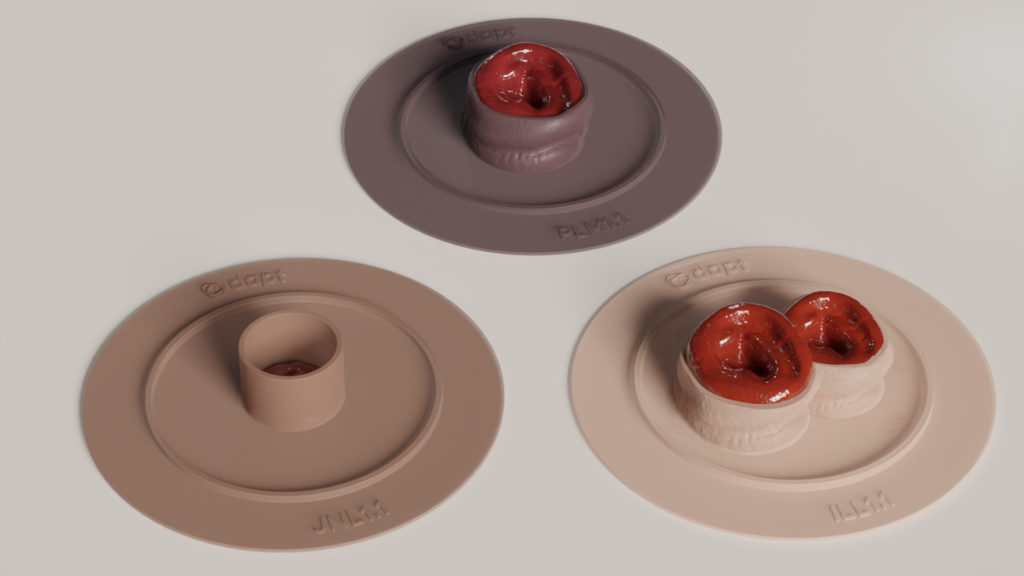

Medical device of personalized wafers for Odapt ostomy bags printed in silicone

Enhanced Productivity

The machine features an interchangeable PEI composite bed, allowing for rapid printing. The S300X has the highest print speed in its category, with a print volume of 300 x 250 x 200 mm.

S300X interchangeable building plate

Robustness and Reproducibility, Print After Print

Calibration is entirely automated, with a single click, using a probe to level the bed and measure the nozzle height and offset. The chamber is temperature-controlled up to 40°C, and the bed up to 80°C. Its active mixing system ensures uniform thermal consistency throughout the printing volume. This feature is particularly valuable for working with a wider range of materials and shaping more complex geometries by adjusting material crosslinking times. The produced parts are uniform, functional, and exhibit excellent mechanical properties.

SIL-001 Industrial silicone air tight joint printing with soluble support

Print Safely

The machine is fully secure with its closed, locked, and filtered chamber. It includes industrial HEPA H14 and activated carbon filters that prevent the release of particles and VOCs (volatile organic compounds) outside the chamber. Its interface allows for fine management of users, procedures, and data, both online and locally.

S300X closed printing chamber

Autonomous Printing

Regarding control, the S300X – LIQ21 | LIQ11 boasts a 10-inch screen for easy navigation through different tabs, along with a web interface available on PC, tablet, and smartphone for remote printer control.

The HUB, a platform that centralizes all necessary data for full use of the S300X – LIQ21 | LIQ11, accompanies you. Find video tutorials, printing profiles, customer support tickets, 3D libraries, and the latest updates.

Details of the S300X with its 10-inch screen

A Team at Your Service

Personalized support is offered to guide you in using the S300X – LIQ21 | LIQ11 to its fullest and provide an optimal user experience through a range of Service Packs.

The S300X – LIQ21 | LIQ11 brings silicone and polyurethane 3D printing to the heart of your projects. It’s an innovative solution developed to increase your potential and push the boundaries, with expertise that makes the existing better and the new possible

Do you want to learn more about how the silicone 3D printer S300X works? Discover the details in our webinar (15 minutes).

Don’t have time? Take 30 seconds to discover it here:

Want to lean more about the S300X? Contact our team.