3D PRINTING IN HEALTHCARE

A research-based partnership

For several years, Lynxter has been working in close collaboration with the University of Paris (formerly Diderot) in the field of medical training and health research.

The University of Paris specializes in a multidisciplinary approach to medical research and training with its diverse disciplines including medicine, dentistry, pharmaceutical science, midwifery and nursing, as well as human and social sciences and other sciences.

Applications of 3D printing in the medical field are numerous: surgical training, educational simulation, pharmaceutical dosage, support in the development of medical devices and in new materials such as medical grade silicone that enable the development of new solutions.

The healthcare simulation center, located in France is equipped with the LYNXTER S600D printer and two different toolheads, FIL33 and LIQ21. The center maintains ongoing research and is involved in major developments in the field of healthcare with 3D printing. The center’s S600D printer was actively used to create protective face shields for healthcare workers during the first wave of the COVID19 pandemic in the 3D4care consortium (teacher-researchers from the university of Paris and the Centrale SupElec engineering school).

The S600D at the University of Paris healthcare simulation center

According to Vincent Lemarteleur, researcher and teacher at the University of Paris, the S600D 3D printer is primarily used for tooling and direct manufacturing.

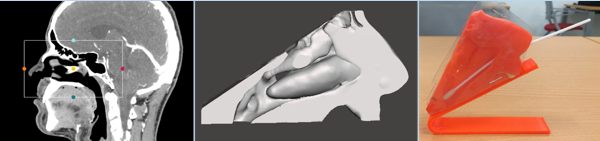

Nasopharyngeal swab training or simulation of foreign body extraction are examples of specific and precise techniques that have been made possible thanks to 3D printing.

Different materials, be they hard (PLA, cellulose composites), soft (TPU, PVA, Istroflex) or liquid (silicone 30 shore A and 30 shore 00) are used to produce, test and design these medical applications. The modularity and versatility of the S600D are invaluable assets for successful completion of a wide range of projects and contribute to revolutionary advances in healthcare.

Case Study: Using a 3D-printed simulator for nasopharyngeal swab collection training

The Covid-19 crisis has raised numerous questions in healthcare. One of these is population-wide testing in order to measure epidemic curves and to ensure rapid and efficient patient care and management.

Nasopharyngeal simulator

The nasopharyngeal simulator has proven to be an innovative and effective educational tool for training healthcare professionals, and provides clear answers to the two following questions:

> How to improve both the reliability of swabbing and patient comfort without practicing on the patients themselves?

> How to rapidly train large numbers of nursing staff in cities and hospitals?

The accuracy of testing is important in order to control the pandemic. Numerous nursing staff have had to learn a new technical procedure or one that they have rarely performed.

Lack of practice makes nasal swabbing a complex procedure and can increase the risk of false negatives. It has also been necessary to train people who were, up until now, not authorized to perform this procedure (firefighters, caregivers and first-aiders etc.).

A 3D printed simulator was therefore the ideal solution for quick widespread training of healthcare workers, thus improving the reliability of the specimen while at the same time respecting the comfort of those being tested.

Why 3D printing?

In addition to the technical capabilities of the S600D and 3D printing in general, there are numerous human benefits to 3D printing including:

– Preparation and training for uncommon or rare surgical procedures

– More regular and frequent practicing and a potentially decreased risk of post-operative complications

– Management of stressful situations

– Visualization of pathologies

– Small series production enabling safe repetition of the surgical procedure whilst working alongside experienced surgeons.

Added to this are significant economic advantages, such as economies of scale and iterative development, making it possible to accelerate research and rapidly increase the number of trained practitioners.

Simulation in the field of healthcare has become a major tool for training healthcare providers. Financial and ethical constraints are key factors when exploring the educational possibilities of 3D printing. New improvements in the generalization of 3D modeling based on medical imaging data can reduce these financial constraints, enabling professionals to print organs directly at a lower cost without the need for additional tools such as molds and counter-forms.

A use case example: a simulator for pediatric pyeloplasty

The aim of this data acquisition-modelling and 3D printing is to enable the learning of new techniques or precise or rare surgical procedures and to repeat them safely.

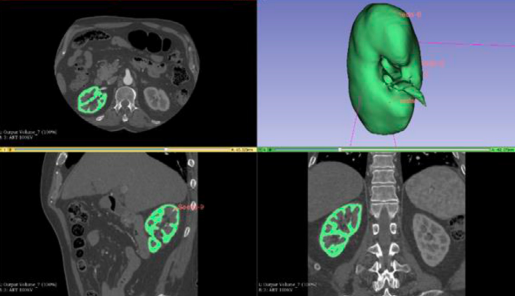

Segmentation of nephron using 3D slicer region growing module

Segmentation of nephron using 3D slicer region growing moduleIn this study, the aim was primarily to design and print a low-cost, an environmentally-friendly simulator depicting the upper urinary tract with abnormal anatomical variants requiring a complex surgical procedure such as pyeloplasty, and secondly to evaluate the similarities with the actual surgical procedure in humans.

Highly experienced surgeons used the 3D printing process to design, manufacture, and evaluate a simulator dedicated to pyeloplasty: a surgical procedure to remove a blockage from the tube that drains urine from the kidney to the bladder. In procedures such as pyeloplasty, the complexity of the learning curve is mainly due to difficulties in acquiring suturing skills.

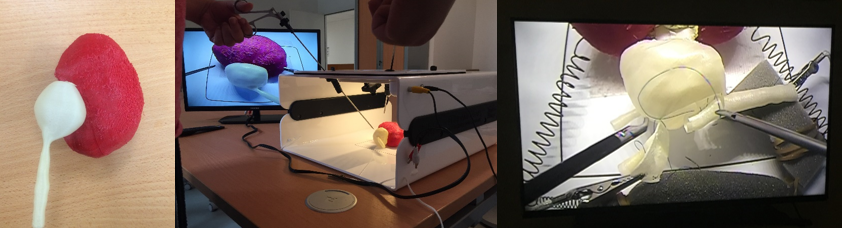

With the aid of open-source and computer-aided design (CAD) software, 3D models of a renal parenchyma, a renal pelvis and a ureter were created. With its ability to extrude up to 3 materials, the S600D printer was used to create a physical prototype of the upper urinary tract. This renal apparatus was processed and printed with additive manufacturing using soft polymer materials (TPU). Polyvinyl alcohol (PVA) was used to print the components in order to make them dissectible and to evaluate their use in surgical teaching.

Some of the materials used for printing were biodegradable and no harmful chemical solvents were employed for the post-treatment of the printed parts or to clean the machines.

The results of the study focus primarily on three elements: needle penetration, thread-sliding, and cutting strength. Suture strength for the pelvis and ureter was rated positively as were handling and mobility properties. The primary difference identified was a difference in elongation between the PVA material and the real biological tissue.

Pyeloplasty simulator in final form and model set up.

Pyeloplasty simulator in final form and model set up.

It is therefore feasible to generate and print upper urinary tract models using patient imagery data along with environmentally and user-friendly products that can be employed effectively in surgical training. The simulator is capable of reproducing the sensations of a surgical procedure at a low cost. 3D printed models can provide new simulation possibilities in variety of surgical fields and make the practices widely available.

You need more information about those 3D printing case studies?Contact us now. .

(1) Vincent Lemarteleur, Matthieu Peycelon, Jean-Louis Sablayrolles, Patrick Plaisance, Alaa El-Ghoneimi et Pierre-François Ceccaldi

Sources

Journal of Surgical Education – Volume 00 – 06.2020

Vincent Lemarteleur – Centre de simulation en Santé, Université de Paris