New silicone formulations for 3D printing

What’s new in the range of silicones compatible with the Lynxter ecosystem? COP has redesigned its silicones for greater performance.

New developments in the range of silicones compatible with the Lynxter ecosystem: COP Chimie rethinks its silicones for greater performance!

New formulations, new reactivities—what are the advantages of this new version of the COPSIL 3D range?

Since 2022, the S300X – LIQ21 | LIQ11 has enabled additive manufacturing of silicone elastomers, as well as the use of a soluble sacrificial material, SUP-001. Among the compatible silicone materials, the COPSIL3D range is composed of RTV2 silicones from 5 to 40 Shore A.

In 2025, the range evolves with redesigned formulations to push printing performance further. The result: the ability to produce larger parts, significantly improved mechanical properties, and higher-resolution printing for even more precise details.

To better understand the stakes of this evolution and the specifics of the new formulations, we spoke with two experts from COP Chimie: Géraldine Gagnevin, Sales Manager, and Aurélien Carrez, Operations Director. Both shed light on the origins of the collaboration with Lynxter, the specifics of the new silicone range, and the opportunities opened by this innovation. COP would also like to thank Cédric Sénat, who contributed to the development of this new range and to enhancing this technical expertise.

A technological collaboration in the service of 3D silicone

How did the partnership between Lynxter and COP Chimie come about?

GG: This partnership was born out of COP Chimie’s desire to offer silicones adapted to new market expectations in orthopedics—our main market—particularly in terms of customization and digitization of processes.

Since innovation is at the heart of our DNA, we launched a project in 2016 to formulate a range of printable silicones. To ensure the industrial success of this initiative, it was essential to build a strong ecosystem combining material and machine. It was within this framework that the collaboration with Lynxter naturally emerged.

What convinced us to work together was a shared vision: reactivity, flexibility, and a common DNA focused on innovation and technological investment.

Beyond Lynxter’s machine expertise and brand image, the quality of the exchanges between our teams (R&D, sales, communication) quickly created a dynamic, smooth, and effective collaboration.

How do your respective areas of expertise complement each other?

GG: Lynxter is one of the most advanced players in bi-component liquid printing technologies, with expertise in materials and printing processes. This skillset complements our know-how at COP Chimie, where we translate our clients’ needs into custom formulations.

Bi-component silicone formulation

Our mastery of bi-component silicones, combined with our ability to test materials in-house, allows us to meet the technical requirements of the process. This close collaboration enables us to develop silicones perfectly adapted to 3D printing, balancing process compatibility with mechanical performance at the level of industrial silicones.

What were the key steps in the development?

GG: It all started with a 4-year thesis, which allowed us to fully understand the requirements of the 3D printing process and lay the foundation for the formulation. The first range was launched at the ISPO Lyon trade show in 2021 with Lynxter present. With the arrival of the new S300X – LIQ21 | LIQ11 machine, the range was then adapted to the needs of medical and industrial applications.

Géraldine Gagnevin in the COP Chimie R&D lab

What challenges did you face?

GG: One of the main challenges was making silicones compatible with 3D printing. We had to develop a specific formulation capable of meeting several simultaneous constraints: viscosity, dimensional stability, curing time, and maintaining the printed shape…

An iterative process on the formulations made it possible to improve the reliability of the process and the mechanical properties of the parts. Thanks to a multidisciplinary approach combining polymer chemistry, process engineering, and rheological modeling, an optimized formulation was developed.

Another major challenge was industrialization. We had to adapt silicone manufacturing and packaging processes to meet the growing market demand driven by Lynxter.

New silicone formulations for 3D printing

What are the main features of this new range?

AC: This new formulation is characterized by an adjusted working time of 50 minutes, better suited to the parameters of the S300X – LIQ21 | LIQ11 machine, which offers support deposition. This delay makes deposition easier by reducing the risk of premature vulcanization in the mixers and improving the resolution of printed parts.

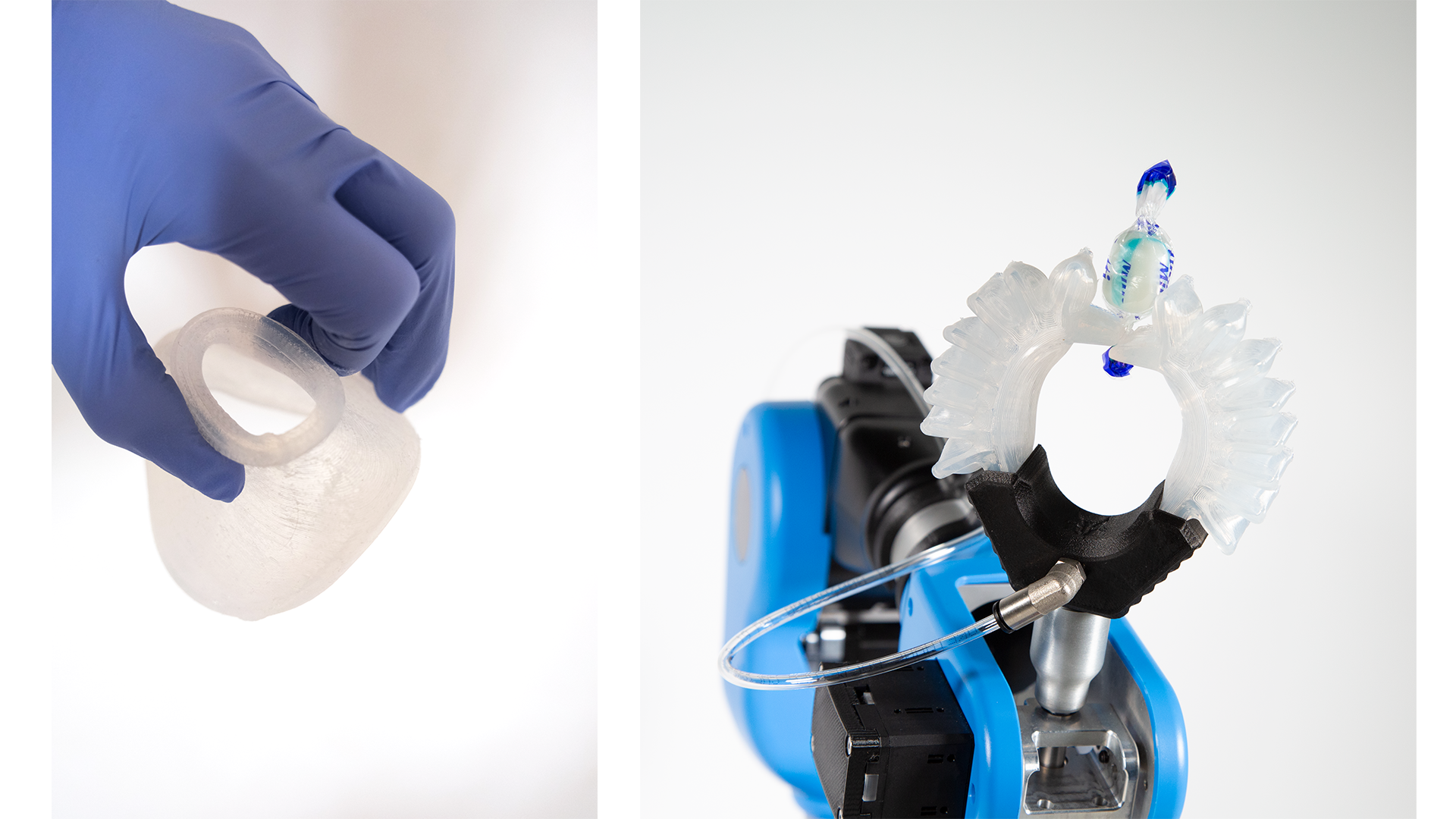

Printing a respiratory mask in COPSIL 1050 with a support material on the S300X – LIQ21 | LIQ11

It is more tolerant of occasional ratio variations, particularly in the case of imperfect mixing, without compromising mechanical performance. This tolerance enhances process reliability.

Improvements have also been made to low-hardness silicones: the formulation no longer sticks, making handling easier, while maintaining the option to keep an adhesive effect if necessary. Finally, the stability of the parts after printing has been improved thanks to better control of collapse.

New COPSIL 3D 1050 range in 55 ml syringes

How does this range differ from previous versions?

GG: While keeping our base of raw materials, we have revised our formulation strategy and its catalytic system to provide robustness, durability, and ease of use.

Like the previous ranges, this new formulation is available in 55 ml syringes or 850 ml cartridges to meet the demand for larger-format prints.

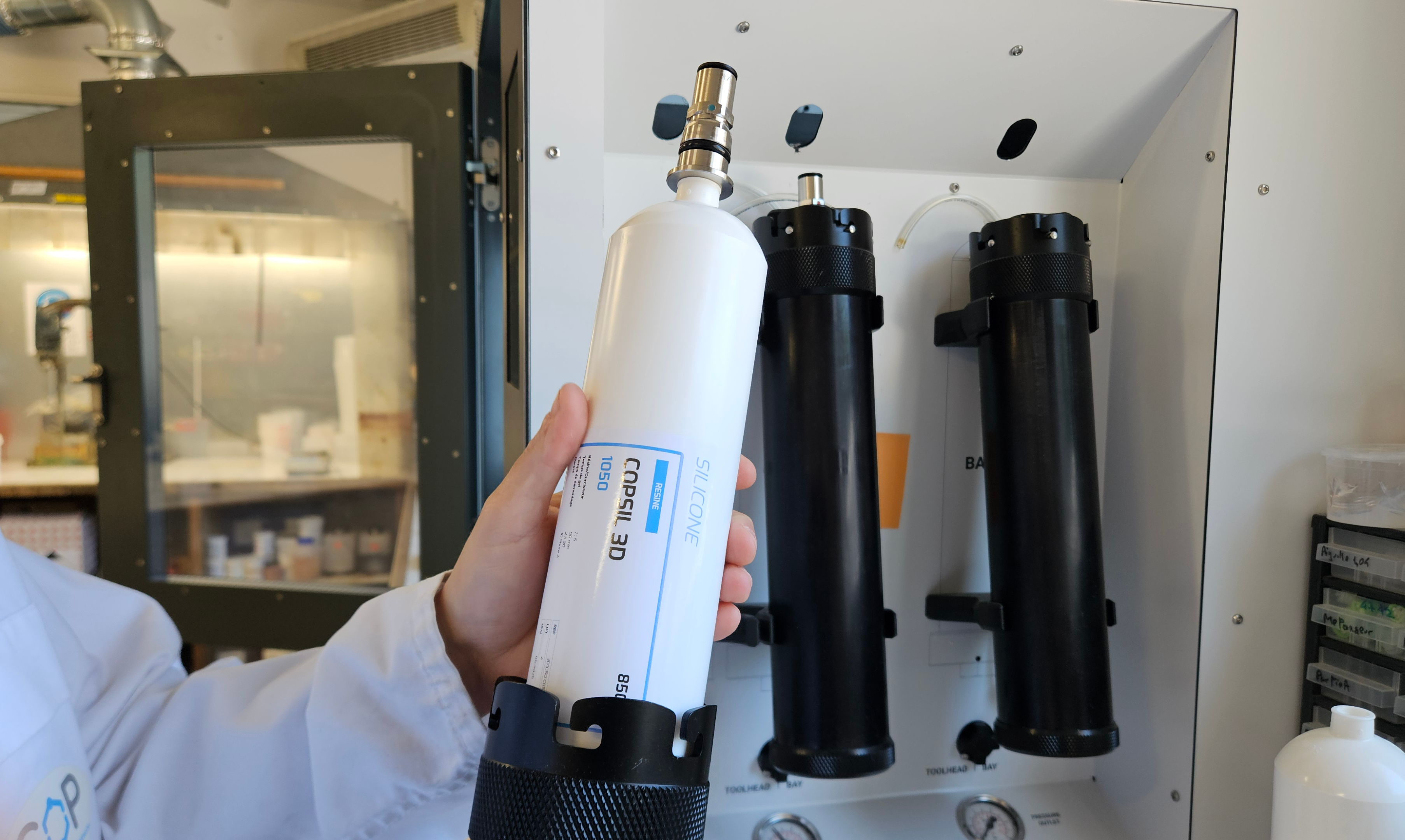

COPSIL 3D cartridge for the S300X – LIQ21 | LIQ11 printer

What applications is it intended for?

GG: This range is specifically designed for use with the S600D and S300X – LIQ21 | LIQ11 printers. It meets the needs of several sectors:

– Orthopedics: custom sockets, insoles, cushions, patellar rings, soft inserts, and orthoses.

– Medical: surgical simulation devices, external prostheses

– Industrial: prototyping and concept validation, masking, industrial-quality spare parts, gaskets, bellows

– R&D: flexible components for soft robotics

Respiratory mask and soft-robot printed in silicone

How were these silicones formulated to be compatible with 3D printing?

AC: The formulation is based on a balance between rheology and reactivity. The viscosity has been adjusted to allow smooth and stable extrusion. At the same time, the reactivity has been adapted to ensure a sufficiently long curing time to allow complete printing, including with support deposition, while ensuring good cohesion of the part once printed.

What performances were you targeting?

AC: We worked on the entire process: conveying, extrusion, printing. The goal? To achieve stable, smooth, reproducible printing. Mechanical properties were also optimized.

What feedback have you received?

AC: The initial feedback is very positive. Users appreciate the reduction in technical issues, easier implementation, and strong mechanical results.

What role did Lynxter play in this development?

AC: A central role. Feedback from their technical teams and end users highlighted a limitation: a curing time that was too short (25 minutes) for the S300X – LIQ21 | LIQ11.

We therefore adapted the formulation to extend this time, without compromising performance.

And what’s next?

CS: We are building a joint R&D roadmap based on field feedback on these new formulas. In the coming years, we will consider functionalized formulas to expand applications…

A strategic innovation

What role does 3D silicone printing play in the evolution of your offerings?

GG: 3D silicone printing plays an increasing role in the evolution of our offerings, particularly in the field of orthopedics. We have long supported orthoprosthetists by providing them with materials suitable for the manufacture of custom devices.

With the advent of digital tools (scanning, modeling, printing), additive manufacturing is becoming an effective solution for producing customized devices such as sockets, insoles, or orthoses. To support this evolution, we are adapting our range of silicones to help our clients through this technological transition.

Any other joint projects on the horizon?

GG: We are actively continuing the development of our 3D range, relying on field feedback from our partners. These exchanges feed our roadmap, with clearly identified work areas: broadening the range in terms of hardness, optimizing post-processing steps, and developing solutions compatible with gel-bath printing, which makes it possible to support complex parts during deposition.

To discover how our silicone solutions can transform your projects, feel free to contact us.