Disability: these 3D printed ergonomic devices that make everyday life easier

How can 3D printing of ergonomic devices improve comfort for people with disabilities?

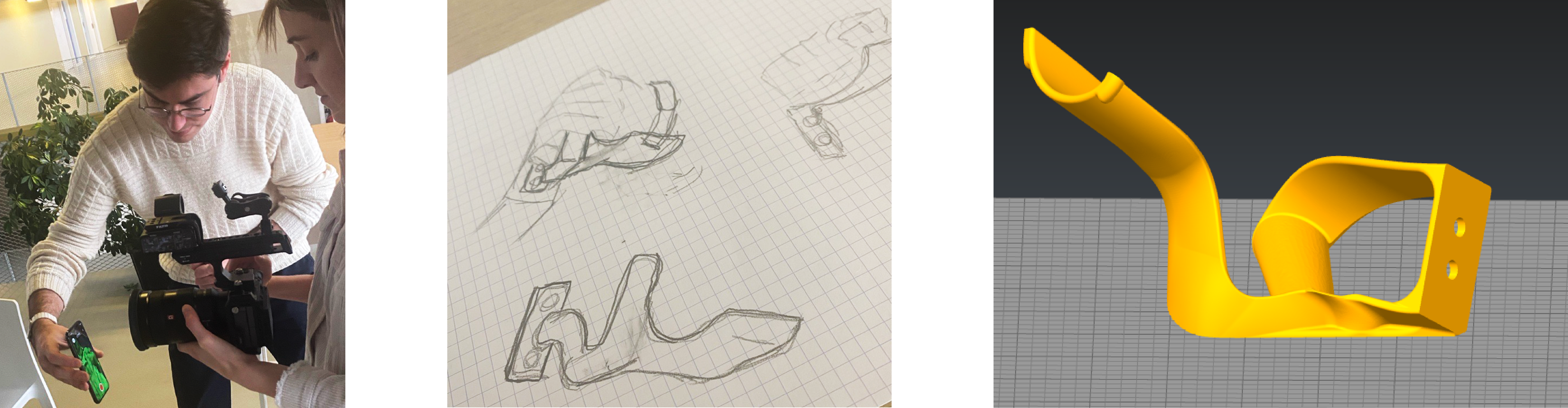

Marion Mouchague is a professional videographer. Her camera as a best friend and as a professional tool never leaves her side. Hours and entire days are spent filming. The weight of a camera is significant. This is even more so when you are living with a disability. This is Marion’s reality, as she has been disabled in her right hand since childhood. Because of her disability, Marion struggles to hold her camera effectively.

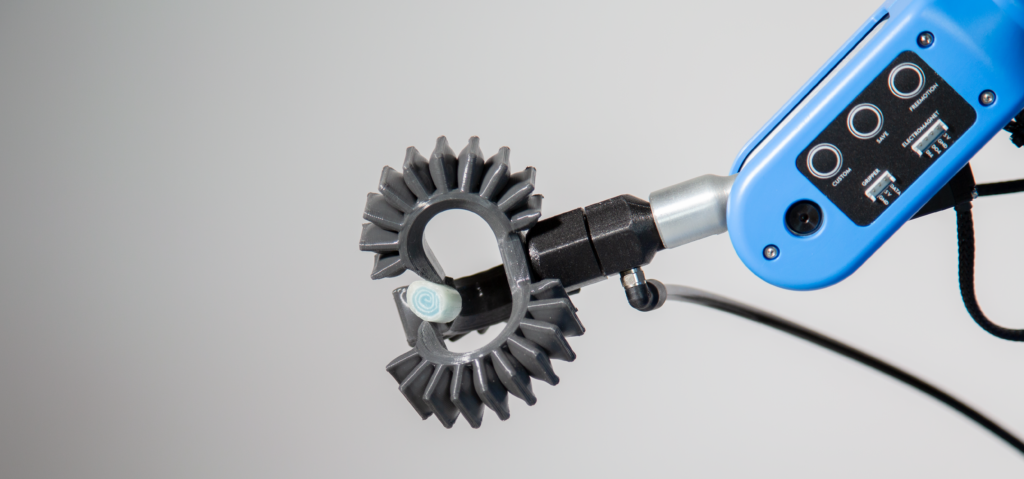

A customized camera handle

After a film shooting, Marion approached Lynxter to see if we could provide a solution to make her professional and personal life easier using 3D printing. Exhaustive research showed that no traditional solution exists on the market. The accessory must be personalized.

The concept is to 3D print an ergonomic handle to improve Marion’s comfort and autonomy, as the current handle on her camera is unsuitable for her disability.

Steps to 3D print a customized handle

We scan her hand in 3D using a smartphone. Then we sketch various concepts by hand to deduce the best approach at this stage. We can then model in 3D on a suitable CAD software the first prototype of the part.

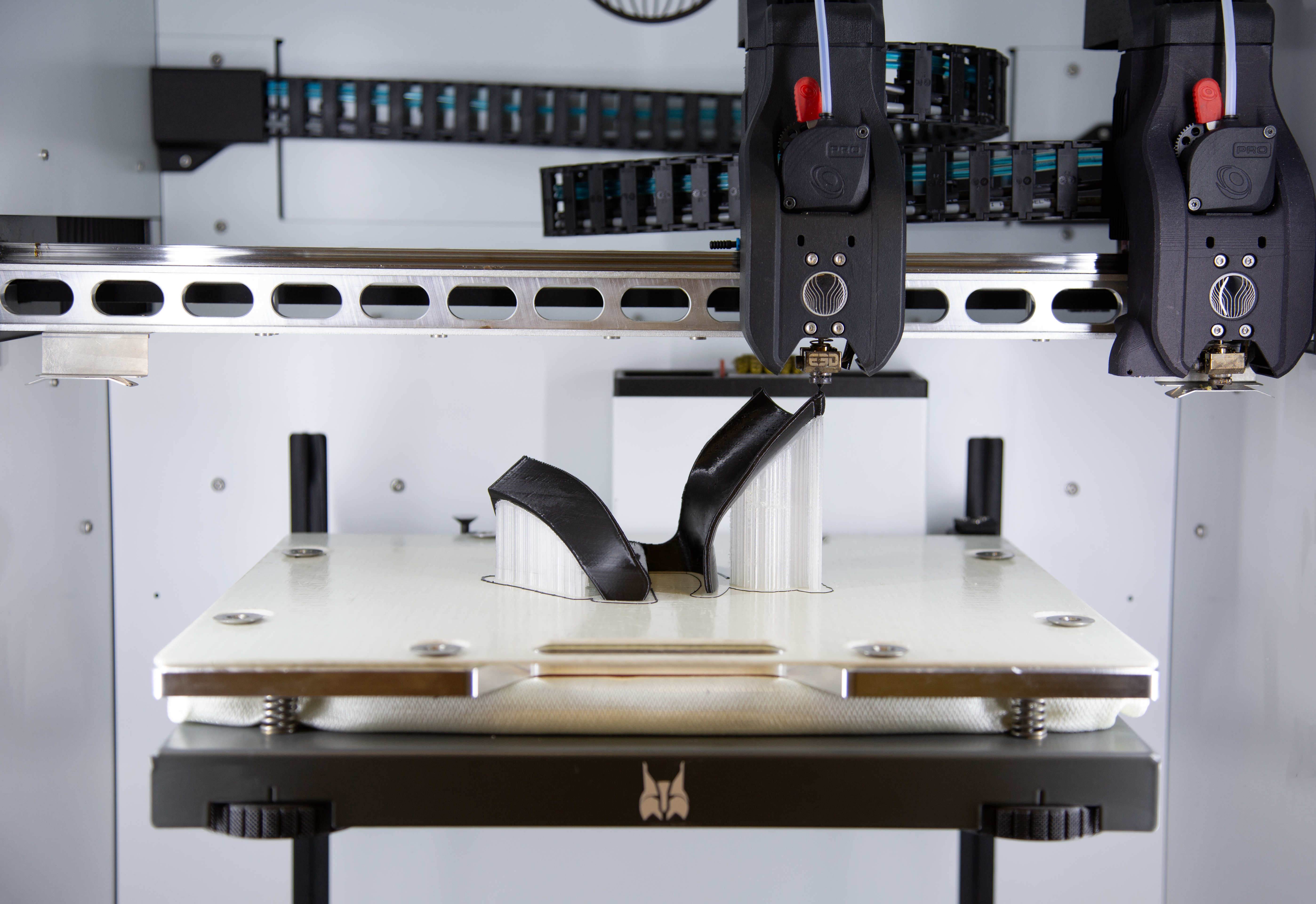

Next, we print the part on the S300X – FIL11 | FIL11 using PETG. The choice of material is crucial. The one selected is flexible with a soft touch, perfectly suited for prolonged skin contact without discomfort. It is commonly used in certain prosthetics, such as test sockets for lower limb prostheses.

Rapid iteration thanks to 3D printing

Marion tries the prototype.

“This will clearly change everything!” declares Marion Mouchague.

Some adjustments are still needed to make the handle fully optimal. Once again, thanks to 3D printing technology, we can iterate on the piece with remarkable speed and precision. The design is quickly refined before manufacturing the final version of the part.

The 3D printed handle

We chose a thermoplastic that is lightweight, impact-resistant and allowing for slight flexibility.

The handle was printed on the S300X – FIL11 | FIL11 from Lynxter. The MEX filament deposition technology (FFF, FDM…) with dual independent extruders (IDEX) is fully adapted to this type of printing and has several advantages:

- Simple and fast

- Does not require post-processing (long and sometimes toxic)

- Easy to print complex orthopedic shapes thanks to the use of the second print head for easily removable supports

- Robust, affordable, durable, recyclable materials that are well-established in the medical field

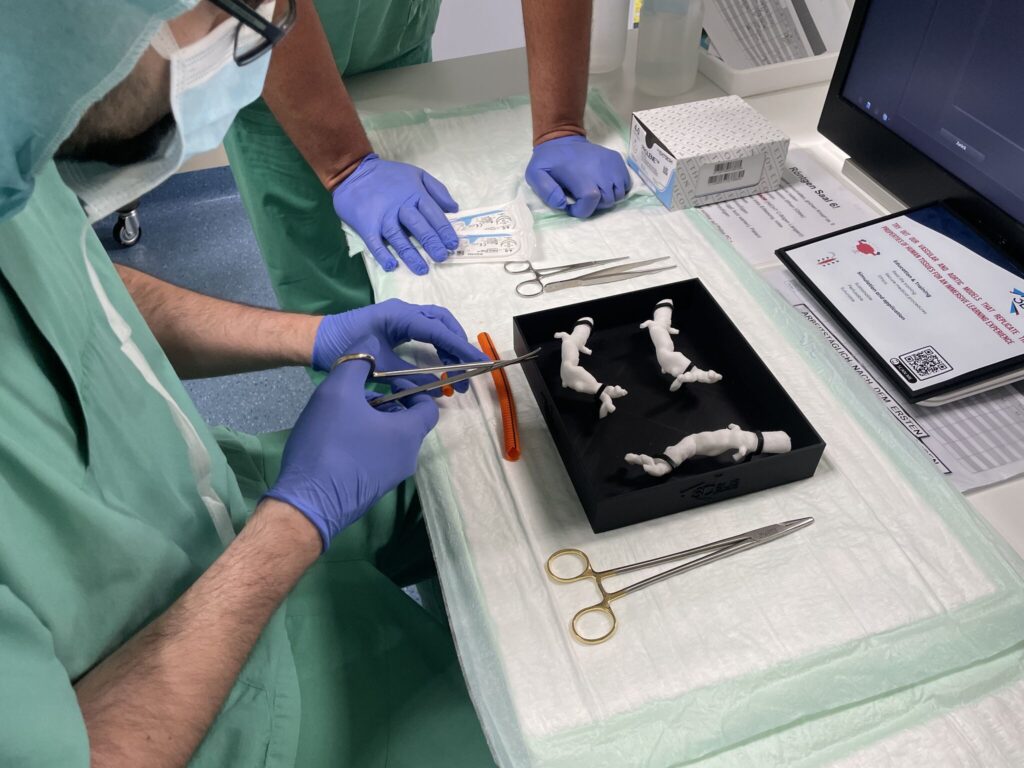

3D Printing of ergonomic silicone devices

Thermoplastic filaments are not the only materials that can be used for rapid prototyping and customization via 3D printing. Lynxter, as an expert in silicone 3D printing, also develops elastomer 3D printing solutions, with skin-contact certified materials that offer additional benefits such as flexibility, elasticity, and sealing.

With the S300X – LIQ11 | LIQ21 elastomer 3D printer, occupational therapists have access to a new technology for creating custom parts aimed at improving patient comfort and mobility. It is also possible to print pieces with complex designs thanks to the machine’s IDEX technology and its ability to print a fully soluble support material.

Today, specialized healthcare facilities can easily integrate this technology by collaborating with external service providers (such as 3Deus Dynamics, for example) or by internalizing the technology with a team trained in CAD and 3D printing.

More information on the subject: Using silicone 3D printing for disability support

Action!

Marion is smiling. Camera in hand, she continues her activity with ease and dexterity.

About Marion Mouchague

She specializes in creating brand films, portraits, and documentaries.

Her approach is to offer brands a personalized visual communication strategy by creating films and campaigns focused on the human aspect. The goal is to share the brand’s values through inspiring life experiences, thus creating deep emotional connections with the target audience. Why? To strengthen the brand’s impact by crafting captivating and memorable visual narratives.