AM Village 2024: Functional Elastomer 3D Printing

Future Solution for Maintenance in the Defense Sector

Created in 2021, AM Village is the new event where additive manufacturing innovation serves the needs of European armies and Defense institutions.

In its second edition, Lynxter, a French manufacturer of 3D printers and a pioneer in elastomer printing (silicones and polyurethanes), offers unprecedented solutions tailored to the specific needs of the defense sector, where the ability to quickly and on-demand print robust parts is crucial for maintaining the operational availability of land, sea, and air vehicles.

The armed forces increasingly rely on additive manufacturing. Various military groups and departments have integrated this technology to repair and enhance their equipment, recognizing its numerous advantages: ease of use, time savings, elimination of tooling costs, and no minimum production requirement.

Lynxter Stand at AM Village 2024

Lynxter Stand at AM Village 2024

Additive Manufacturing in Defense: Meeting the Challenges of MCO

Additive manufacturing is recognized as a key solution in the framework of maintaining operational readiness of equipment and vehicles. It allows the armed forces to produce spare parts and equipment without delay, in any quantity, and close to operational theaters. This reduces supply delays and quickly puts equipment back into service, minimizing the risk of critical part shortages.

Lynxter’s multi-material machines offer turnkey solutions (machines, materials, and printing profiles) to facilitate the operations of defense stakeholders, both governmental and industrial.

The modular 3D printer S600D can print ceramics, thermoplastics, and elastomers by simply changing the tool head. The S300X – LIQ21 | LIQ11 is exclusively dedicated to bi-component liquids, elastomeric materials such as silicones and polyurethanes. Equipped with IDEX technology and support materials, the S300X enables the creation of complex geometry parts that are flexible and resistant, meeting damping, sealing, and protective needs with temperature resistance: [-50°C; + 250°C]. In early 2024, the S300X received the UAF label “Used by the French Armed Forces” awarded by the Ministry of Defense.

Ludivine Dedonder – Belgian Minister of Defense, and Clément Lull – Lynxter

AM Village 2024: Presentation of Additive Manufacturing in Defense

AM Village 2024 was held from May 13-17 in Tournai, Belgium. The event hosted over 400 additive manufacturing enthusiasts from the armed forces, industry, and academia. The European Defense Agency, responsible for organizing the event, recorded a record number of participants, all taking part in the various interactions proposed during the week: seminars, workshops, briefings, and demonstrations, all focused on the application of additive manufacturing in a military context.

The event aims to develop interactions between European Armies and Industries, considering additive manufacturing as an effective solution for urgent repairs, temporary repairs, and addressing the obsolescence of parts (discontinuation of spare part production by original manufacturers). Beyond these current needs, it is imperative to integrate additive manufacturing into the development and qualification processes of future products, equipment, and vehicles to anticipate spare part solutions of tomorrow, especially when the needs for parts are below the minimum production of conventional manufacturing processes.

AM Village succeeded in its goal of bringing together military demands and solution providers, such as Lynxter, to meet these MCO challenges. This gathering of experts from the armed forces and industry fostered a better understanding of needs and capabilities, improving military logistics through additive manufacturing.

Application Cases Printed During AM Village 2024

Lynxter presented its 3D printers and especially the 3D printing of elastomers like silicone and PU, producing live concrete application cases for various defense actors in Europe over five days.

Here are some examples produced during 2024:

Flat Gasket:

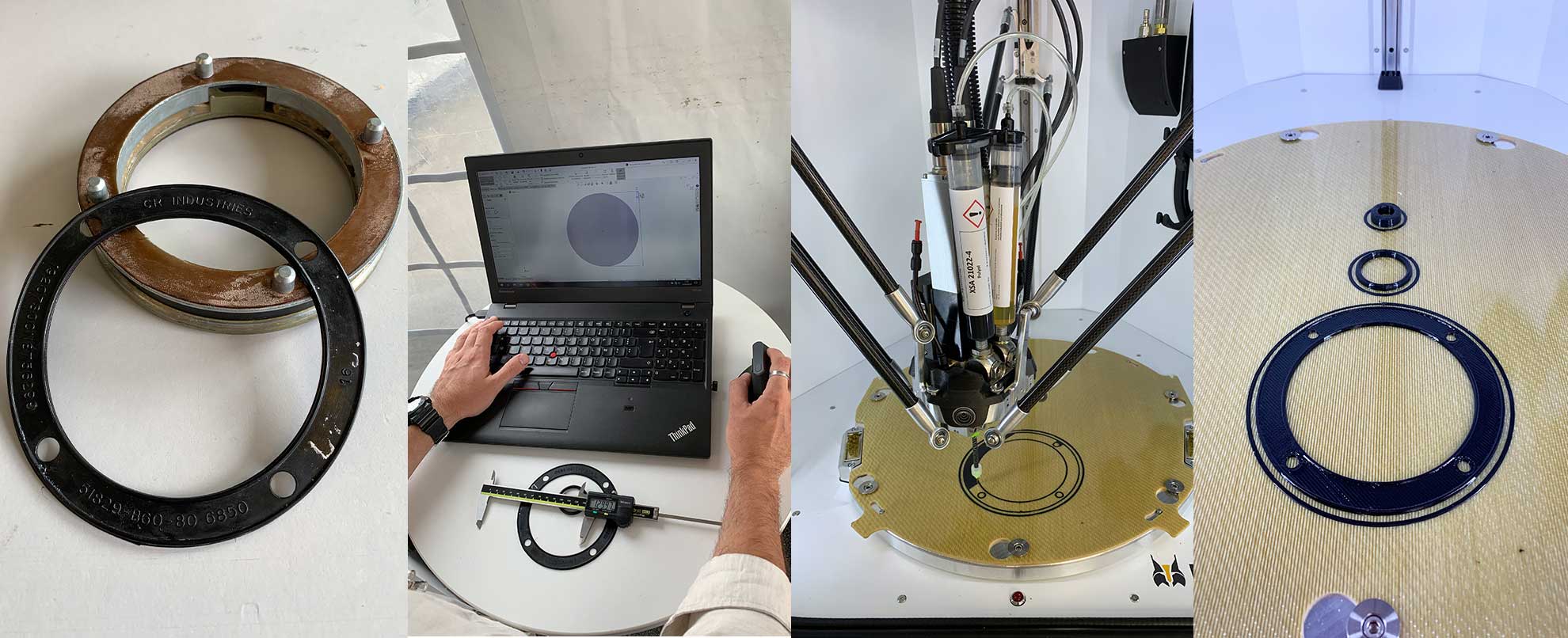

Gasket to be reproduced – CAD modification – PU printing – Final part

Request: Eastern Europe

Straps for Forearm Orthosis:

Straps printed in silicone – Swedish Army

O-Ring:

O-Ring for engine component – printed in PU vs original

Request: Belgian Army

Crankcase Gasket:

Automotive crankcase gasket SIL-001

Request: Belgian Army

Brake Fluid Reservoir and Cap:

Reservoir in PP – Cap in PETG-GF – Lower ring in PEKK-CF

Request: Belgian Army

Silent Block:

Rear cabin silent block printed in PU

Request: Belgian Army

Flat Gasket:

Silicone emergency repair kit bi-component to be cut ready in 24h on average VS printed silicone part ready in 20 min

Request – German Army

The Advantages of 3D Printing Elastomers

While metallic 3D printing has garnered significant attention, Lynxter has made a significant advance with its liquid elastomer functional printing technology. This innovation meets the needs for rapid repairs, temporary repairs, product obsolescence, and even small to medium-scale industrial production. Lynxter’s 3D printers (S600D LIQ11 and LIQ21, and S300X – LIQ21 | LIQ11) enable the printing of industrial and medical quality silicone and polyurethane, known for their heat resistance, chemical resistance, flexibility, and elasticity. These properties make silicone and polyurethane (PU) versatile materials suitable for various demanding applications, producing parts with excellent mechanical, thermal, and chemical properties.

DOWNLOAD THE WHITE PAPER

Download now “Improve your workflow with silicone 3D printing”.

Discover how this new technology can enhance your productivity and innovation.

Don’t miss this opportunity to gain a new competitive advantage.