S300x

LIQ21 | LIQ11

IDEX SILICONE 3D PRINTER

Lynxter introduces the S300X – LIQ21 | LIQ11, an industrial silicone 3D printer that redefines the realm of possibilities. Explore a compact machine, unparalleled reliability, and unprecedented robustness while benefiting from integrated support printing technology for unlimited design potential in medical and industrial silicones as well as polyurethanes.

Price: from €34,990 excluding tax – Europe.*

Independent Dual Extrusion

Enhance Your Designs with IDEX Silicone Printing

The S300X – LIQ21 | LIQ11 silicone 3D printer is equipped with two toolheads configured in Independent Dual Extrusion (IDEX): the LIQ21 two-component for creating the main part and the LIQ11 single-component for water-soluble support structures

Unlimited design freedom thanks to soluble support

Multi-material printing without cross-contamination

Customizable extrusion : single or double

SILICONE 3D PRINTING, DEMOCRATIZED.

FREE-FORM.

INDUSTRIAL & MEDICAL GRADE.

THE FUTURE OF INDUSTRY

Seals, Masking, Maintenance

The S300X – LIQ21 | LIQ11 silicone 3D printer is designed to meet the needs of the industry. It’s used for the production of surface treatment masks and caps, custom seal printing, emergency repairs, or soft robotics. Production gains in efficiency, responsiveness, production lead time, and innovation.

The S300X – LIQ21 | LIQ11 silicone 3D printer can print industrial-grade RTV2 silicone (45shA) and polyurethane (ranging from 50 to 85 shA).

CHANGING HEALTHCARE

epithesis, orthosis, prosthesis

Silicone 3D printing contributes today to the improvement and simplification of the medical workflow by reducing the number of manual interventions involved in the production of ortheses and prostheses. It is also used to make custom orthopaedic and orthoplastic devices.

The S300X – LIQ21 | LIQ11 silicone 3D printer can print RTV2 silicones certified skin contact from 5 shA to 40 shA (45 sh00 to 86 sh00)

Silicone 3D Printing use cases

INDUSTRIAL Silicone 3D PRINTing

SIMPLE AND EFFICIENT

The S300X – LIQ21 | LIQ11 combines robustness, precision and industrial efficiency in a compact size that fits in any workspace.

The large capacity cartridges allow the silicone printing of large parts or several small ones in complete autonomy, reducing the need for intervention.

Its filtered, heated and silent chamber ensures the safety and comfort of its user.

IDEX TECHNOLOGY.

support for silicone 3D printing.

OPEN ECOSYSTEM.

SILICONE

our expertise

Since 2016, Lynxter has been developing unique and specialized expertise in silicone 3D printing, which is now integrated into the S300X – LIQ21 | LIQ11 printer ecosystem.

The S300X – LIQ21 | LIQ11 prints industrial and medical-grade silicone that is UV-resistant and retains all of its chemical and mechanical properties.

Notable materials include medical-grade RTV2 silicone (5, 10, 25, 40 ShA) certified for skin contact per ISO 10993-05, industrial-grade RTV2 silicone (45shA), and polyurethane (ranging from 50 to 85 shA).

3D Printing MATERIALS

Skip the drama

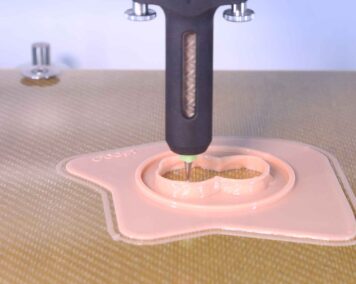

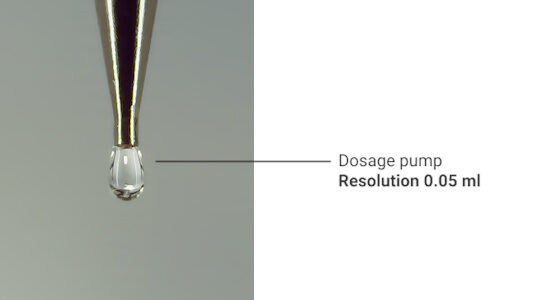

Precision dosage pump

Our high-precision volumetric dosage pump ensures very fine control of the flow with no pulsation, enabling the production of thin layers (50 μm) LIQ with repeatability and, consequently, enhanced reliability.

Try a different approach

with Idex liquid technology

With Idex liquid technology, we can now print silicone materials with water-soluble support, providing access to intricate shapes that were previously unattainable. This technology is exclusively available at Lynxter

Safe and sound

with HEPA 14 filter

The printer features a closed and secure chamber equipped with a HEPA 14 filter – Activated carbon and a locking system to ensure user safety.

No fuss

Automatic calibration

Get the first layer right. Embrace precision and reliability with our surface and inter-nozzle calibrations which guarantee reliable and precise 3D printing results.

Dream big

Versatile materials cartridges.

Our small and large capacity cartridges for silicone and support materials enable the printing of long and voluminous parts.

Do your thing

Open Materials

Go ahead and do your thing. Our open software allows users to access printing parameters. Print your in-house materials and access a wide range of liquid materials.

How to 3D Print Silicone

In just 90 seconds, you’ll finally understand why and how 3D silicone printing is possible.

SPECIFICATIONS

All the technical specifications of the 3D Silicone Printer S300X – LIQ21 | LIQ11

-

Toolhead Configuration

Two-part LIQ21 – one-part LIQ11

Printing Materials

Medical RTV2 Silicone (5, 10, 25, 40 ShA)

Industrial RTV2 Silicone (45 ShA)

Polyurethane* (50 to 85 ShA)

LSR*

Epoxy**Coming soon

-

Extrusion

Single and Dual Independent Extrusion

X,Y,Z Resolution

X-Y: 12.5 μm, Z: 1.0 μm

-

Build Volume

X 300 – Y 250 – Z 200 mm

Dimensions

W 991.22 x L 720 x H 984.5 mm

-

Thermal Environment

Heated Build Plate: 20°C to 80°C

Heated Enclosure: 20°C to 40°CLayer Height

50 μm to 1 mm

-

Build Surface

Removable

Hot-Swappable

Machined SurfaceMaximum Tool Speed

X-Y : 500 mm/s, Z : 40 mm/s

-

Automatic Calibration

Build Surface Leveling

Machine Geometric Correction

Tool Height Calibration

Inter-nozzle Offset CalibrationControl

Stand-alone Touchscreen and Web Interface

-

Connectivity

Ethernet

Manufacturing Format

Standard Gcode

-

User Health and Safety

Double HEPA H14 Filtration

Activated Carbon

Machine Access LockingManufacturing Job Security

Consumables Run-out Detection

Printing Resumption after Power Loss -

Configurable Firmware

Customizable Lynxter Firmware (based on RepRap firmware) – Simplify3D Software (slicer).

Power Supply

100/230V AC 8A 50-60 Hz

Contact Our Experts

Do you need a silicone part and want to internalize small or medium series production?

Save valuable time and reduce your costs. Order your S300X – LIQ21 | LIQ11 silicone 3D printer now.

*To know the price outside of Europe, please contact our sales team.