TWO-COMPONENT LIQUID TOOLHEAD

The liquid printing revolution

Two-component materials

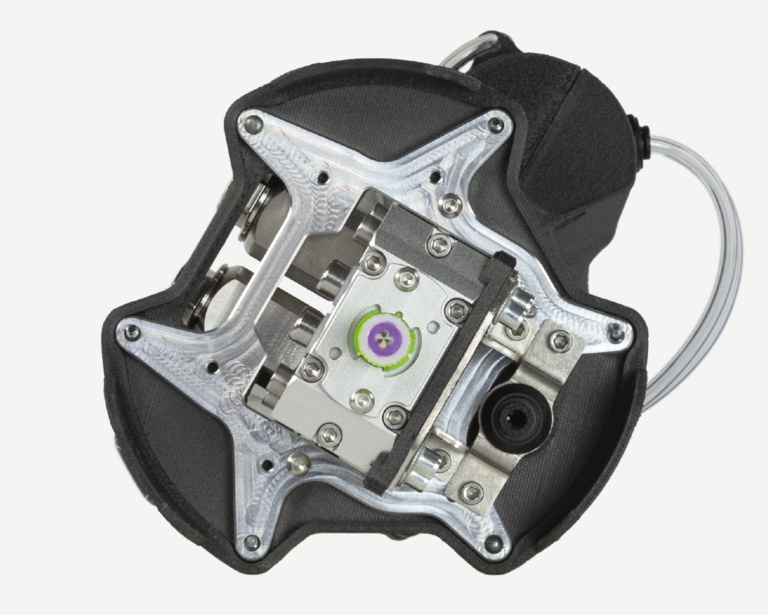

LIQ21 allows 3D printing of two-component silicones and resins, making it possible to print with technical and industrial materials. The LIQ21 toolhead‘s advanced technology guarantees an innovative 3D printing experience.

Silicone (RTV2, LSR) & polyurethane 3D printing

Silicone 3D Printing

consistency and precision

LIQ21 features a volumetric dispensing pump for high-precision dispensing of component A & component B. A static mixer is attached to the printhead and ensures homogeneous mixing.

LIQ21 provides unmatched print quality with fine and precise dispensing.

Two-component silicone additive manufacturing is now a reality.

Applications

High performance and agility

Prototyping, maintenance, custom-made orthopedic devices (contact skin approved), silicone 3D printing allows you to manufacture finished parts without any post-processing. With the LIQ11, use a single silicone material cartridge for your tests and small series, then switch to a larger high-capacity cartridge for larger projects.

- Use a variety of technical and industrial materials in a wide range of hardness levels.

- Nozzle diameters adapted to your project: : 0.34, 0.56, 0.69mm

- Large build volume: Ø390mm x 600mm

MATERIALS

Silicone additive manufacturing

Extensive range of viscosities and hardness levels for 2-component silicones.

Liquid consumables are packaged in 55ml syringes. For larger projects 960ml cartridges can be used.

Choose from materials that Lynxter has already preconfigured on the S600D or try out other materials … DARE to experiment!

LIQ21 TOOLHEAD FEATURES

Technical specifications

-

Extruder

Liquid two components (two parts)

Viscosities

10-3 Pa.s to 2000 Pa.s

Volumetric flow rate

0.03 to 6.60ml/min

Interchangeable nozzles

Ø0.22mm to Ø1.04mm

Maximum dispensing pressure

20 bars

Maximum speed of the tool

150mm/s - 9000mm/min

Thermal environment

50° C

Pump rotor and stator

High chemical resistance

Easy to use

Easy to dismantle and clean