A key step forward for silicone 3D printing – Lynxter and 3Deus Dynamics form a strategic partnership

Following several years of rapid growth, the silicone 3D printing market has matured and gained in clarity with key players organizing themselves around increasingly advanced technologies and ever more demanding applications. Lynxter, the leading global OEM for 3D printing of industrial and medical elastomers, and 3Deus Dynamics, owner of the patented Dynamic molding technology and 3D manufacturing facility certified for healthcare and aeronautics applications, have signed a strategic partnership.

What is Dynamic Molding?

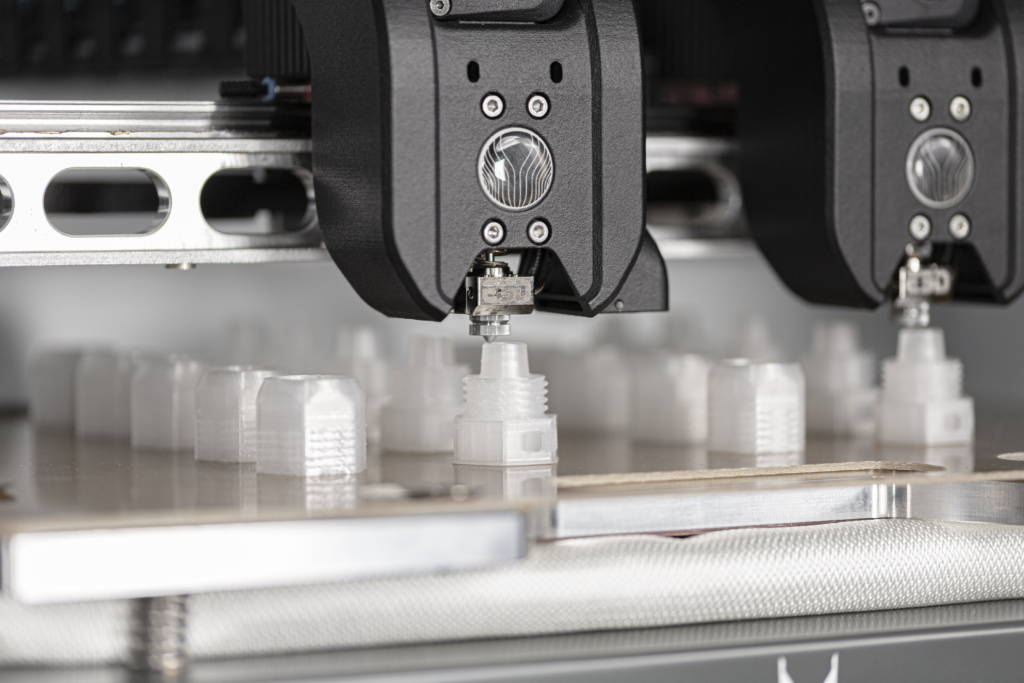

Dynamic molding, a multi-patented process invented by two researchers from the CNRS center in Lyon and developed by 3Deus Dynamics in France, is a new branch of the MEX (Material EXtrusion, or FFF/FDM/LDM) process. It involves the automated deposition of a strand of material into a bed of powder and combines the benefits of traditional MEX technology (high-quality materials, multi-material compatibility, durability, simplicity and productivity) with the gravity-defying advantages of the granular medium, which allows the material to hold its shape during printing without requiring additional support structures. Consequently, dynamic molding can be used to produce highly complex parts such as anatomical models and replicas of organs and soft tissues, without the need to spend time creating support structures.

In addition, with the possibility to incorporate powders with specific properties into the extruded material, it is possible to create composites with new properties (fire resistance, conductivity, electromagnetic shielding or mechanical reinforcement, etc.).

From an environmental perspective, the powder used as a temporary support during the process can be reused for subsequent prints, making the printing process entirely waste-free. This is a significant advantage that complements a local production process, one that is energy-efficient, sustainable, safe for the user, and free from toxic solvents. As a result, the finished parts have a low carbon footprint while also being highly wear-resistant due to the use of materials with exceptional long-term performance.

At a time when we are questioning the toxicity of photopolymerization 3D printing processes (SLA, DLP, LCD, MJ, etc.) on both users and the environment as well as the long-term durability of parts created using these processes, MEX 3D printing combined with Dynamic molding positions itself as a solution perfectly suited to the needs of our time.

What are the key applications?

- Healthcare

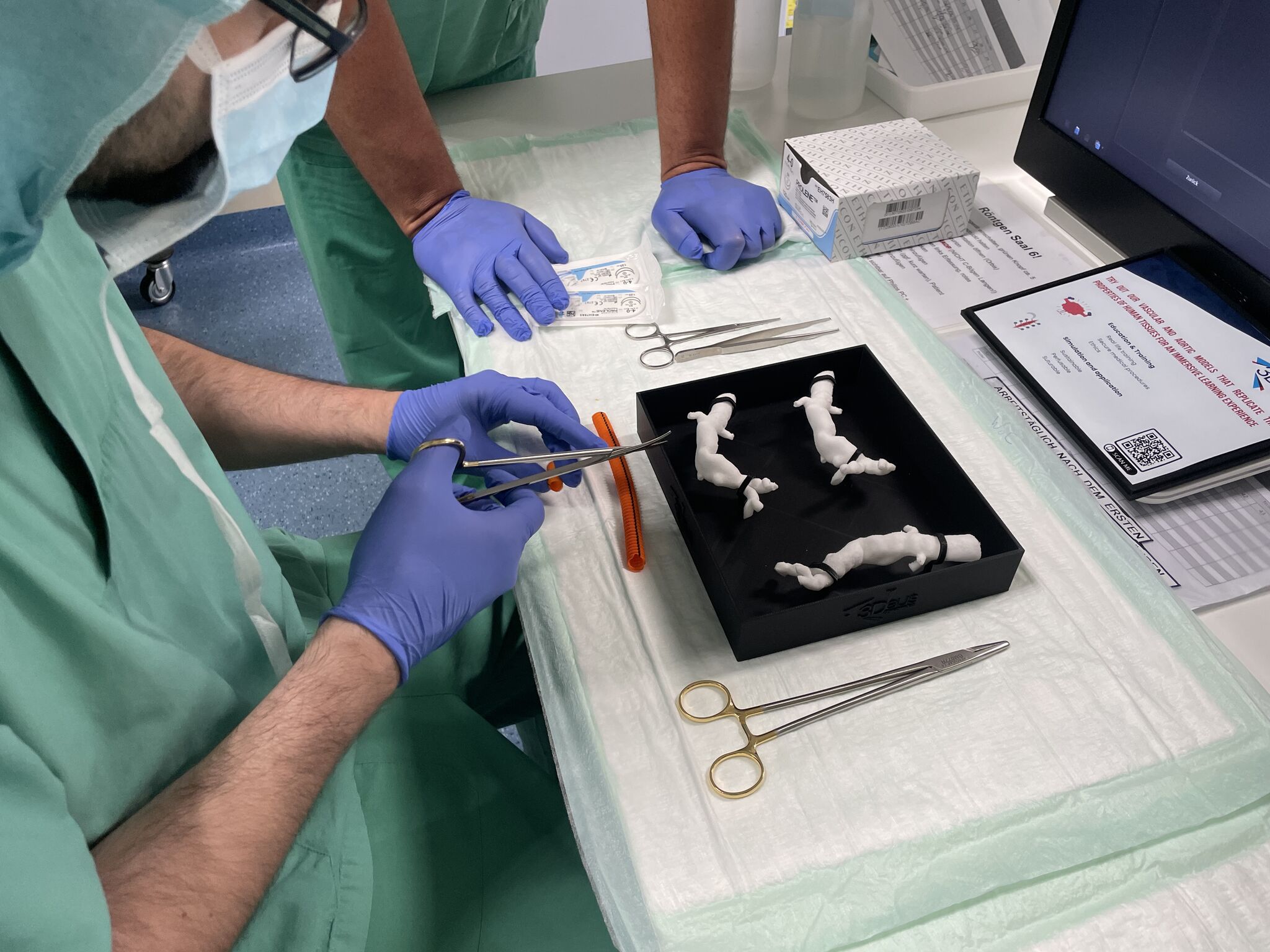

Surgical planning, training, testing and co-development of medical devices, the list is continually evolving, A revolution for healthcare professionals; in addition to heart and vascular surgery, this technology is now also used in oncology, orthopedics, urology and gynecology. Providing unmatched haptics and biomimetics, it enables simulation of patient-specific surgical procedures with a very high level of morphological and mechanical accuracy. This approach significantly improves training speed, reduces surgical risks, improves patient care and reduces the need for trials on cadavers or animals.

- Aeronautics, industry and defense

Surface treatment masking with high thermal resistance, conductive seals, flexible fire-resistant parts (certified ISO 2685), parts for electromagnetic shielding, and personal protective equipment are just a few examples of the boundless possibilities offered by this innovative technology.

Available now from both the 3Deus Dynamics production center and the Lynxter Application Center.

Do you have a project? Feasibility study, co-development project or serial production, the 3Deus Dynamics research and production center (certified ISO 13485 for the production of medical devices and equipped for the creation of functionalized flexible composites) is open and fully operational, with its Lynxter 3D printers, in the Lyon area. In Bayonne, the Lynxter Application Center is there to assist you with your tests and with solution integration analysis within your establishment.

Coming soon as an optional feature on the S300X – LIQ21 | LIQ11 for exploring this new silicone-based process.

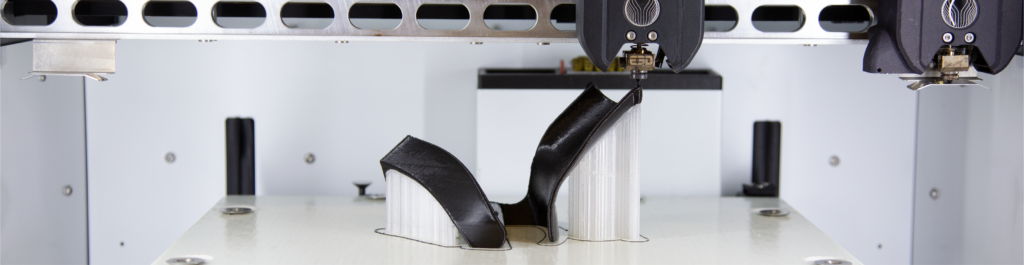

Lynxter and 3Deus Dynamics have teamed up to propose an innovative and pragmatic solution for industry and healthcare professionals. This technology is implemented on the S300X – LIQ21 | LIQ11 through a comprehensive solution that includes:

- A tray adapter kit

- A bundle of silicone material and compatible support powder

- Print profiles to download via the HUB

- A design guide

- Resources and dedicated support hours provided by experts from 3Deus Dynamics and Lynxter.

This 3D printer, a global reference for elastomer 3D printing, is designed and manufactured in France with a network of local partners. It is fully integrated into a proven, efficient and open ecosystem which has established the reputation of Lynxter and 3Deus Dynamics over the years.

Contact us to discuss your projects with the Lynxter Application Center or 3Deus Dynamics Start, Innov & Print.

About 3Deus Dynamics

3Deus Dynamics is a company with expertise in the additive manufacturing of silicone parts and functionalized soft composites with properties such as conductivity, electromagnetic shielding, fire resistance, mechanical reinforcement etc.

A team of expert 3D printing engineers and Doctors in soft matter science forms the foundation of our expertise, which enables us to produce complex parts of virtually unlimited shape and with characteristics superior to those achieved using current manufacturing techniques.

At present, our company primarily serves the healthcare, aerospace, and defense markets. However, our unique expertise also allows us to meet the needs of other industrial sectors.

About Lynxter

Based in France, we design and build industry 4.0 additive manufacturing machine tools. Experts in our field, our aim is to democratize 3D printing by proposing quality tools and high-performance solutions to professionals in all sectors (industry, healthcare, R&D, defense, luxury goods etc.). We are leaders in elastomer 3D printing.

The expertise of Lynxter’s support and development services allows wide access to cutting-edge know-how and ensures an optimal user experience.