CRAMIK ADDITIVE SOLUTIONS and LYNXTER team up to revolutionize high-temperature ceramic applications.

CRAMIK ADDITIVE SOLUTIONS, S.L. ceramic materials, and Lynxter, the modular 3D printing manufacturers, are joining forces in 2025 to develop next-gen slurry pastes.

Together, we’re taking high-temperature abrasion resistance to the next level with advanced materials like Alumina, Cordierite, and Silicon Carbide. This partnership blends Cramik’s deep expertise in engineering, ceramics, and innovative materials with Lynxter’s tech-savvy, high-performance paste 3D printers.

Our goal? To meet the demands of industries that need materials tough enough to handle the heat—literally.

Why does this collaboration matter?

CRAMIK’S material portfolio sets up a new standard for high-temperature abrasion resistance materials, and LYNXTER’s open ecosystem is the perfect playground to ease innovation and manufacture high-performance parts.

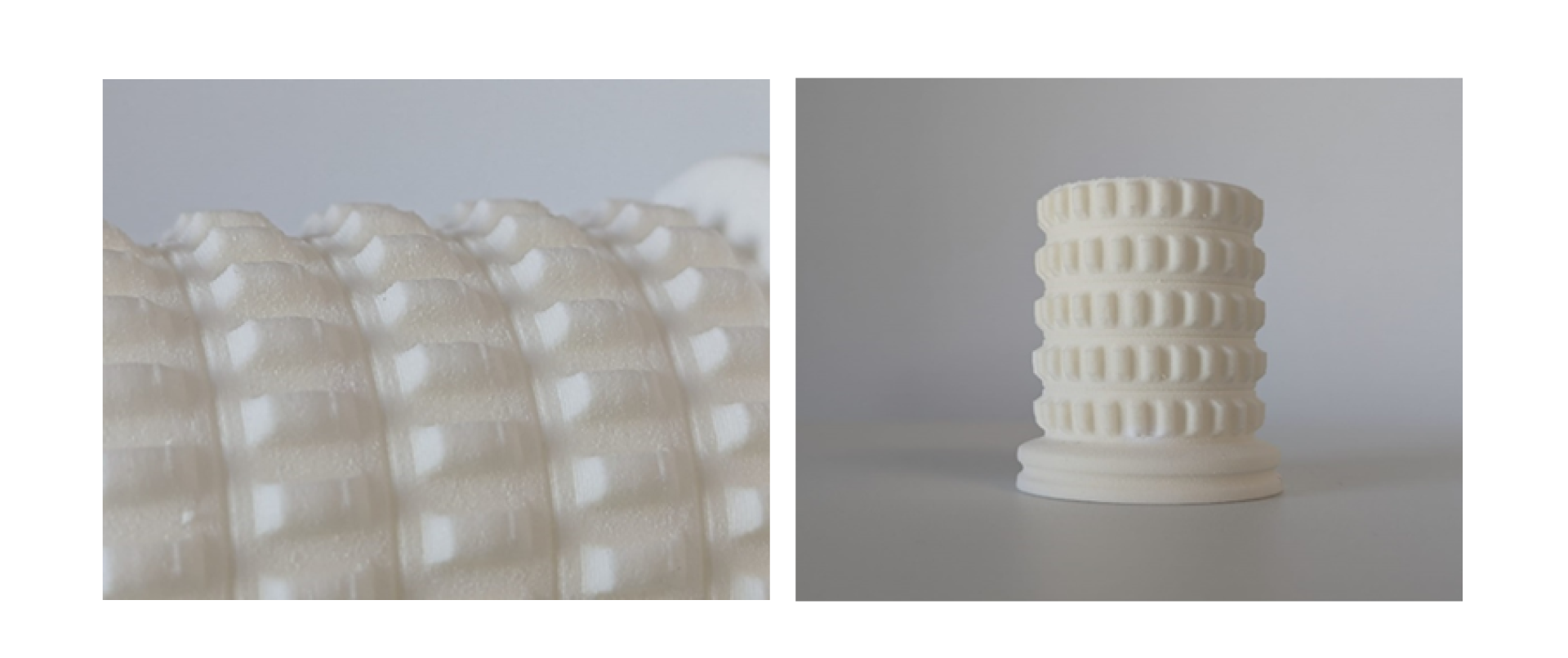

Thanks to the paste format, material can contain a high quantity of ceramic powder (higher than what’s possible in thermoplastic filament), allowing high-density parts after debinding and sintering. The denser the parts, the better the final mechanical, thermal, and electrical properties.

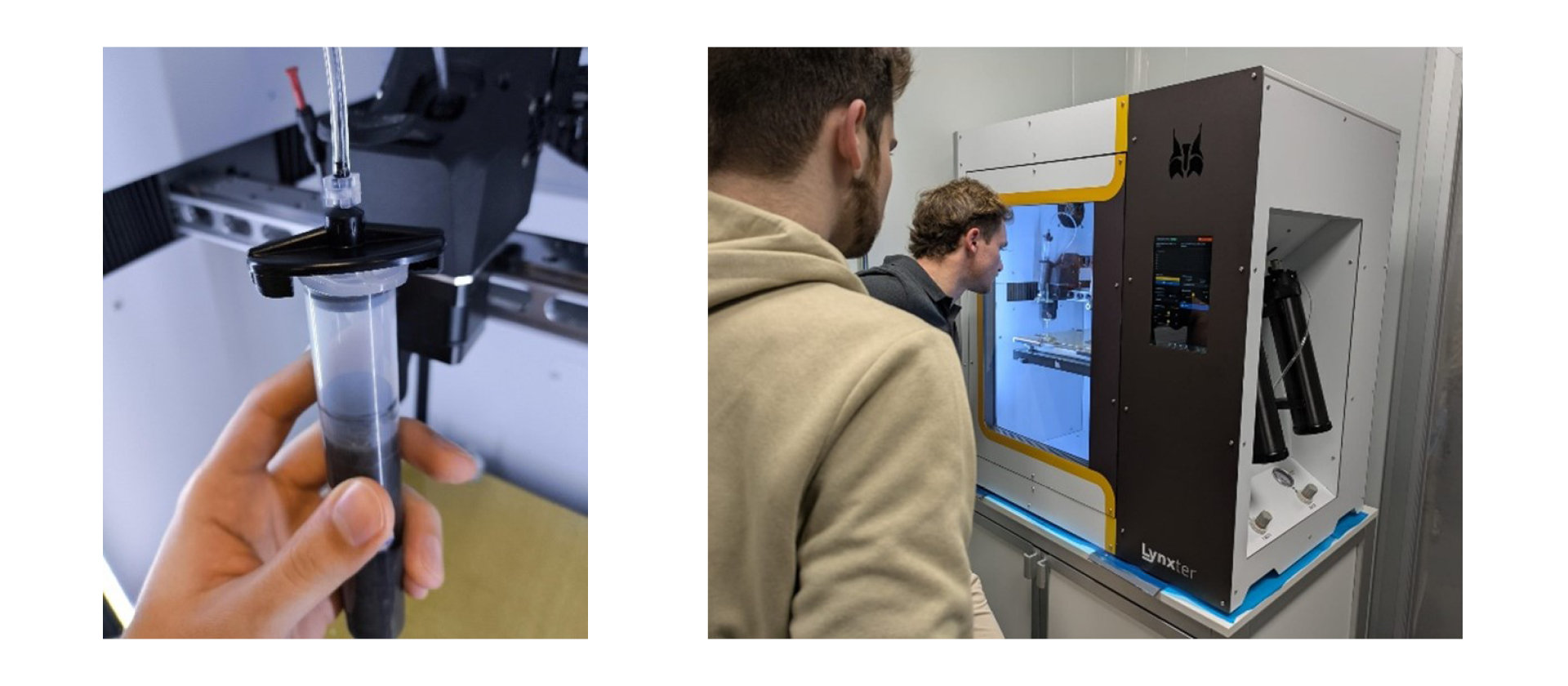

The LYNXTER S300X – PAS11 | PAS11 is easy to use and facilitates formulation iterations. CRAMIK materials are made to be thermally debinded with no dangerous solvents needed and cover a large range of industrial applications.

Lynxter’s commitment to R&D

Lynxter’s DNA remains R&D, always staying at the forefront, responding to the evolving demands of industries, and even anticipating future needs. Their laboratory is in constant search for increasingly high-performance solutions, like the ones offered by the Spanish company.

“This collaboration is all about pushing limits to introduce solutions that can resist above 1.000°C for industrial additive manufacturing”

Alberto Santana, business manager.

Lynxter’s flagship S600D and S300X printers are rockstars when it comes to handling complex, high-performance materials. Together, we’ll create slurry paste formulations optimized for stability, durability, and heat resistance—standing strong even beyond 1,600°C.

What’s on the horizon?

- Next-Level Materials: Designing advanced slurries with alumina, cordierite, and silicon carbide for extreme industrial applications.

- Unparalleled Flexibility: Opening doors to more use cases.

- Simplified Post-processing: New formulas with no need for chemical debinding agents.

“We’re thrilled to join forces and offer our users an extensive catalog of possibilities within the same open industrial ecosystem.”

Thomas Batigne, CEO of Lynxter

When people think of Lynxter, they often recall the softest and most elastic 3D-printed parts they’ve ever handled. With Cramik, they’ll now have access to the exact opposite—a sample of the hardest and stiffest 3D-printed parts they’re likely to encounter.

This remarkable range is made possible through deep collaboration and years of expertise.

Looking to develop technical ceramic 3D printing projects?

Contact us via the Lynxter Application Center or Cramik Additive Solutions.

About Cramik Additive Solutions

Cramik is based in Valencia, Spain, and leads the charge in engineering ceramics blended materials for advanced manufacturing technologies. Their innovative HYPERBINDER CRAMIO enables extreme condition resistance with confidence.

About Lynxter

Lynxter is an industrial 3D printer manufacturer and a global leader in elastomer 3D printing. Based in France with fewer than 50 employees, the company develops machines, materials, and software.

Recognized for its expertise in silicone additive manufacturing, Lynxter has received multiple innovation awards and actively contributes to scientific advancements.

Its product range includes the S600D, a modular, universal 3D printer, and various versions of the S300X, a high-performance, specialized IDEX 3D printer capable of printing silicone, polyurethane, thermoplastics, and even ceramics.

Lynxter offers an open ecosystem with industrial standards in service, quality, and performance. Operating internationally, the company serves leading industries in aerospace, healthcare, defense, luxury, and scientific research.