FOR CERAMIC 3D PRINTING

Get creative with PAS11 technology

3D Print ceramics on your S600D

Our aim: to design a toolhead that combines freedom with creativity and innovation.

The PAS11 toolhead suits all types of projects, from industrial to research or art.

Print with alumina, cordierite, zircon, porcelain, stoneware, clay, etc.. the list of printable materials is constantly evolving!

High precision ceramic AM

Say Yes! to high precision ceramic additive manufacturing!

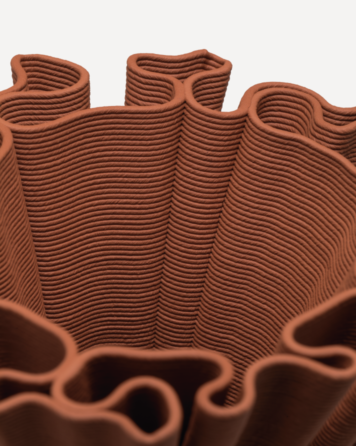

PAS11 features a microdispensing pump allowing the material to be dispensed precisely without it shearing. The PAS11 toolhead for ceramic 3D printing is pressurized in order to ensure continuous extrusion. The deposited strands of paste are fine, precise and regular.

An safe and ergonomic design for both operation and cleaning

PAS11 technology

PAS11: The perfect tool for innovation and creativity

PAS11 sets standards in terms of technical performance and is revolutionizing ceramic 3D printing

- Wide variety of compatible pastes

- Wide variety of compatible pastes

Large build volume: Ø390mm x 600mm - High-speed movement

- Precise and accurate strands

- Modular: add extra functions to the PAS11 toolhead to widen the field of applications

MATERIALS

Ceramic pastes for 3D printing are packaged in 55ml syringes.

Materials with pre-configured profiles on the S600D are available, or you can use the ceramic paste of your choice and experiment freely! PAS11 gives you the freedom to choose from a wide range of different ceramics.

PAS11 TOOLHEAD FEATURES

Technical specifications

-

Extruder

Single component

Viscosities

10-3 Pa.s to 2000 Pa.s

Volumetric flow rate

0.05 to 5.50ml/min

Interchangeable nozzles

Ø0.69mm to Ø1.04mm

Printing volume

⌀ 380mm x 600mm

Maximum dispensing pressure

Max 10 bars

Maximum speed of the tool

150mm/s - 9000mm/min

Thermal environment

40° C max

Pump rotor and stator

Abrasion resistance

Print job protection

Precise flow start and end points