LA tête-outil IMPRESSION 3D céramique

La créativité vous appartient

À vous l’impression 3D céramique sur votre S600D

Notre ambition : créer un équipement permettant de conjuguer liberté, inventivité, créativité et innovation.

PAS11 s’adresse aussi bien aux projets industriels qu’aux projets artistiques et aux projets de recherche.

Alumine, Cordiérite, Zircone, Porcelaine, Grés, Argile, …

Une grande précision

Osez la fabrication additive céramique

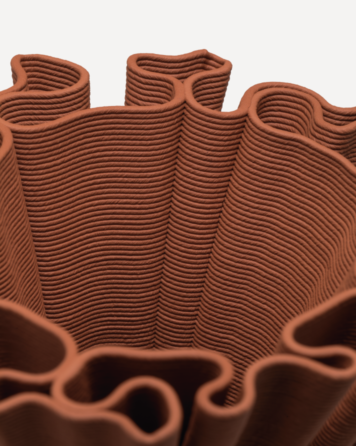

PAS11 est équipée d’une pompe de microdosage permettant de doser le matériau précisément sans le cisailler. La tête outil PAS11 pour l’impression 3D céramique, est mise sous pression afin de maintenir une extrusion constante. Les cordons déposés sont fins, précis et réguliers.

Ergonomie optimale pour l’utilisation et pour le nettoyage – Fonctionnement sécurisé

La technologie PAS11

L’impression 3D pour l’inventivité et la créativité

PAS11 instaure une norme en matière de performances techniques et révolutionne l’impression 3D céramique

- Large diversité de pâtes compatibles

- Grand volume d’impression : Ø390mm x 600mm

- Rapidité de déplacement

- Précision et netteté des cordons

- Modulable : ajout de nouvelles fonctions à votre outil PAS11 pour augmenter le champs des applications

LES MATÉriaux DE LA PAS11

Les pâtes céramiques pour l’impression 3D sont conditionnées sous seringues de 55ml.

Des matériaux profilés sur la S600D sont disponibles, mais vous pouvez aussi utiliser les pâtes céramiques de votre choix et expérimenter en toute liberté. PAS11 vous offre la liberté de choisir des céramiques variés

LES FONCTIONNALITÉS DE LA PAS11

Découvrez l’ensemble des caractéristiques techniques de PAS11

-

Ligne d'extrusion

1 ligne d'extrusion - mono composant

Viscosités

10-3 Pa.s à 2000 Pa.s

Plage de débit

0.05 à 5.50ml/min

Buses interchangeables

Ø0.69mm à Ø1.04mm

Volume de fabrication

⌀ 380mm x 600mm

Pression de départ

10 bars max.

Environnement thermique

50°C max.

Vitesse de déplacement de l'outil

150mm/s - 9000mm/min

Utilisation simplifiée

Facilement démontable et nettoyable

Sécurisation du job de fabrication

Détection fin de consommable

Rotor et stator

Grande résistance à l'abrasion